Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Distilling Department Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

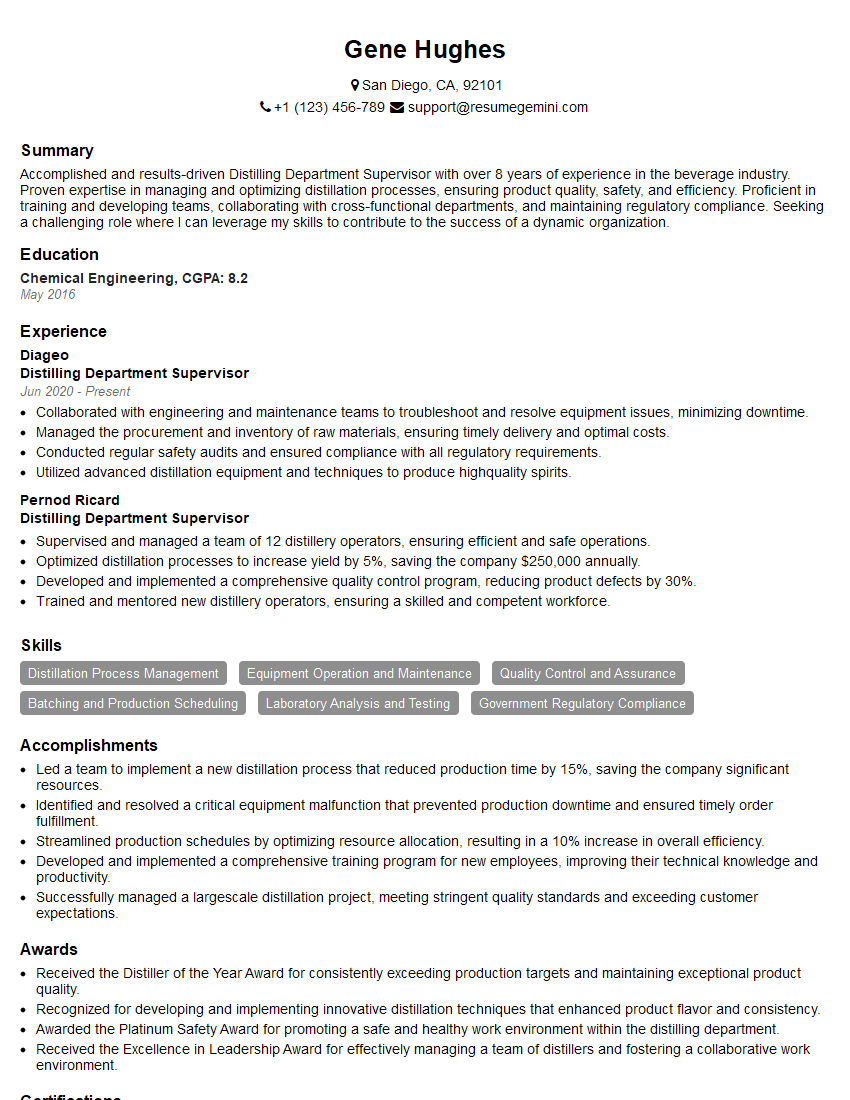

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Distilling Department Supervisor

1. What are the key responsibilities of a Distilling Department Supervisor?

- Supervise and manage all aspects of the distilling process, including the operation of equipment, maintenance of quality standards, and training of staff.

- Develop and implement distillation plans and procedures to ensure efficient and cost-effective production.

- Monitor and control the distillation process to optimize yield, quality, and efficiency.

- Troubleshoot and resolve any issues that arise during the distillation process.

- Work closely with other departments, such as production, quality control, and maintenance, to ensure smooth operations and meet production targets.

2. Describe the different types of distillation equipment and their applications.

Batch Distillation

- Used for small-scale production or for producing specialty products.

- Involves filling a still with a liquid mixture and heating it until the desired components vaporize.

- The vapors are then condensed and collected.

Continuous Distillation

- Used for large-scale production of high-purity products.

- Involves feeding a liquid mixture continuously into the still and removing the vaporized components as they are produced.

- The still is operated at a constant temperature and pressure to ensure consistent product quality.

Fractional Distillation

- Used to separate liquids with similar boiling points.

- Involves using a column with multiple trays or plates to create a series of partial condensations and vaporizations.

- The vapors rise through the column, and the components with lower boiling points condense at lower trays, while the components with higher boiling points condense at higher trays.

3. How do you ensure the quality of the distilled products?

- Establish and maintain quality control standards for all aspects of the distillation process.

- Monitor and test raw materials, in-process products, and finished products to ensure they meet specifications.

- Conduct regular equipment calibration and maintenance to ensure accurate and reliable measurements.

- Implement and follow Good Manufacturing Practices (GMPs) to ensure product safety and quality.

- Document all quality control procedures and results to maintain traceability and accountability.

4. How do you optimize the distillation process for efficiency and cost-effectiveness?

- Analyze and identify areas for improvement in the distillation process.

- Implement process improvements, such as optimizing equipment settings, reducing energy consumption, and minimizing waste.

- Monitor and track key performance indicators (KPIs) to measure the effectiveness of process improvements.

- Collaborate with other departments to identify and resolve bottlenecks and inefficiencies.

- Stay up-to-date with industry best practices and new technologies to continuously improve the distillation process.

5. What are the safety protocols and emergency procedures that must be followed in the Distilling Department?

- Identify and assess potential hazards in the Distilling Department, such as flammable liquids, high temperatures, and confined spaces.

- Develop and implement comprehensive safety protocols to minimize risks and protect employees.

- Train staff on safety procedures, including proper handling of hazardous materials, use of personal protective equipment (PPE), and emergency evacuation procedures.

- Conduct regular safety audits to ensure compliance with safety protocols and identify areas for improvement.

- Establish and maintain an emergency response plan to effectively manage any incidents or accidents.

6. How do you manage a team of distillers and ensure their productivity and motivation?

- Provide clear instructions and expectations to team members.

- Delegate tasks effectively and empower team members to make decisions within their scope of responsibility.

- Foster a positive and collaborative work environment where team members feel valued and respected.

- Recognize and reward employee achievements and contributions.

- Provide opportunities for professional development and growth.

7. What are the challenges you anticipate facing as a Distilling Department Supervisor and how would you address them?

A key challenge for a Distilling Department Supervisor is ensuring consistent product quality while optimizing production efficiency and cost-effectiveness. To address this, I would implement rigorous quality control measures throughout the distillation process, conduct regular equipment maintenance and calibration, and monitor key performance indicators (KPIs) to track process effectiveness. I would also collaborate with other departments to identify and resolve any bottlenecks or inefficiencies.

Another challenge is managing a team of distillers and ensuring their productivity and motivation. To address this, I would focus on providing clear instructions and expectations, delegating tasks effectively, and fostering a positive and collaborative work environment. I would also recognize and reward employee achievements and provide opportunities for professional development and growth.

8. How do you handle conflicts or disagreements within your team?

When conflicts or disagreements arise within my team, I prioritize open and respectful communication. I facilitate discussions to understand the perspectives of all involved parties and work towards finding mutually acceptable solutions. I encourage team members to express their concerns and ideas constructively, and I strive to create a safe and inclusive environment where diverse opinions are valued.

9. How do you stay up-to-date with industry best practices and new technologies related to distillation?

To stay up-to-date with industry best practices and new technologies related to distillation, I actively participate in industry conferences, workshops, and online forums. I also subscribe to industry publications and research journals to stay informed about the latest developments and innovations. Additionally, I seek opportunities to collaborate with experts in the field and visit other distilleries to learn from their experiences and best practices.

10. What are your strengths and weaknesses as a Distilling Department Supervisor?

Strengths:- Strong technical expertise in distillation processes and equipment.

- Proven ability to optimize production efficiency and minimize costs.

- Excellent leadership and communication skills.

- Commitment to quality and safety.

- Ability to work effectively in a fast-paced and demanding environment.

- Limited experience in managing a large team.

- Could be more proactive in identifying and resolving potential issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Distilling Department Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Distilling Department Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Distilling Department Supervisor plays a pivotal role in overseeing the distillation operations, ensuring the production of high-quality spirits and maximizing efficiency. Their responsibilities encompass the following key areas:

1. Production Management

Supervising the production process to ensure adherence to safety standards, quality protocols, and production schedules.

- Managing and scheduling production shifts, assigning tasks, and monitoring progress to optimize productivity.

- Ensuring compliance with regulatory requirements, industry best practices, and company policies.

2. Quality Control

Maintaining the highest standards of quality by conducting regular inspections and implementing quality control measures.

- Monitoring the distillation process, verifying product specifications, and conducting sensory evaluations.

- Investigating and resolving quality issues, implementing corrective actions, and refining production processes.

3. Staff Management

Leading and motivating a team of distillers, ensuring their safety, professional development, and productivity.

- Providing training, guidance, and support to staff, fostering a positive and collaborative work environment.

- Conducting performance evaluations, identifying training needs, and mentoring employees for career growth.

4. Equipment Maintenance

Maintaining the efficiency and reliability of distillation equipment, minimizing downtime and ensuring optimal performance.

- Inspecting, servicing, and repairing distillation equipment, collaborating with maintenance teams as needed.

- Participating in preventive maintenance programs and implementing strategies to extend equipment lifespan.

Interview Tips

To ace the interview for a Distilling Department Supervisor position, preparation is key. Here are some tips and hacks to help you highlight your qualifications and make a strong impression:

1. Research the Company and Industry

Demonstrate your knowledge and interest in the company and the distilling industry. Research their products, production process, and market position.

- Visit the company website and industry publications to gather information.

- Attend industry events and connect with professionals in the field.

2. Emphasize Experience and Skills

Highlight your relevant experience in distillation operations, quality control, staff management, and equipment maintenance.

- Quantify your accomplishments using specific metrics and examples.

- Explain how your skills and knowledge align with the job requirements.

3. Showcase Leadership Abilities

Emphasize your leadership qualities, ability to motivate teams, and drive results. Provide examples of successful projects or initiatives you have led.

- Describe how you have fostered a positive and productive work environment.

- Explain how you have mentored and developed your team members.

4. Prepare for Technical Questions

Expect technical questions about the distillation process, quality control protocols, and equipment maintenance. Review your technical knowledge and be prepared to discuss your problem-solving abilities.

- Study the principles of distillation and the equipment used in the industry.

- Prepare examples of how you have resolved technical challenges or implemented process improvements.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Distilling Department Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.