Feeling lost in a sea of interview questions? Landed that dream interview for Fabrication Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fabrication Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

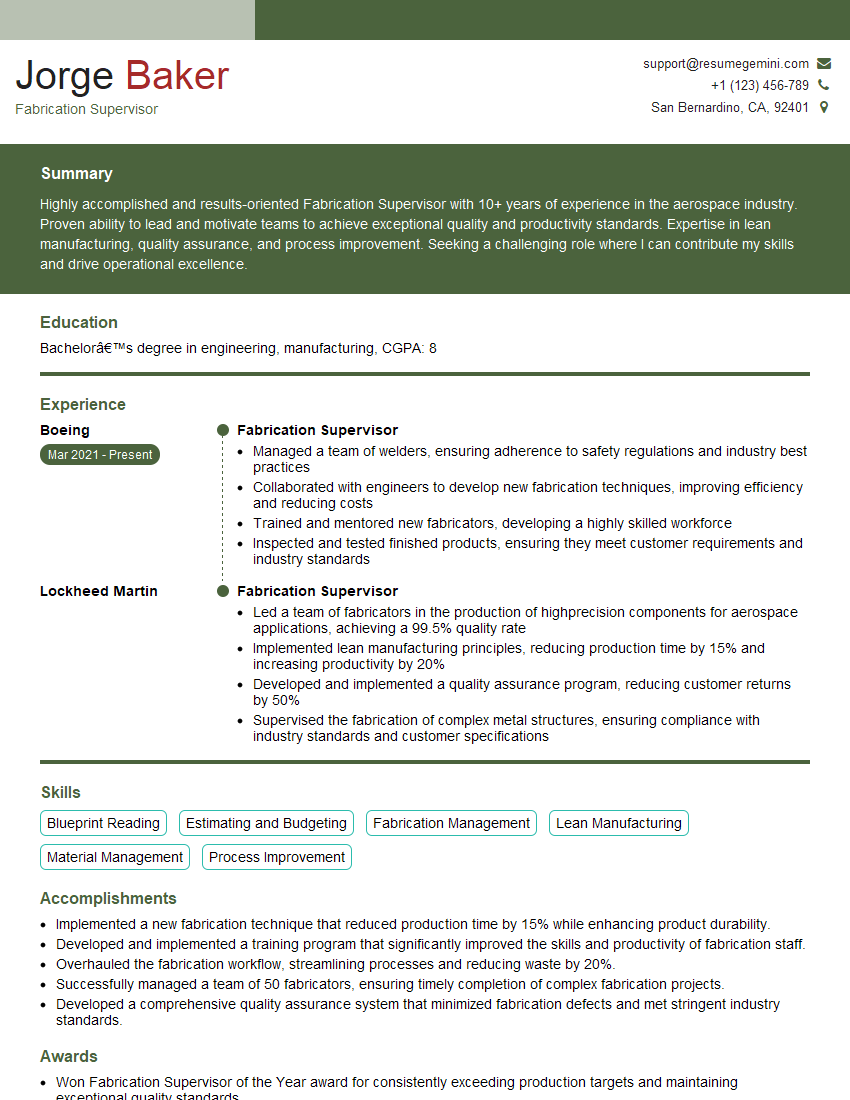

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fabrication Supervisor

1. Explain the process of welding dissimilar metals?

When joining dissimilar metals, several challenges must be considered to ensure a successful weld. Here’s an outline of the process:

- Material Selection: Choose compatible metals that can be welded together. Consider their melting points, thermal conductivity, and coefficient of thermal expansion.

- Joint Design: Determine the appropriate joint type (e.g., butt joint, edge joint) based on the metals and their properties.

- Welding Technique: Select a suitable welding process, such as MIG, TIG, or laser welding, depending on the materials and joint design.

- Filler Metal: Use a filler metal that is compatible with both base metals and provides the desired strength and corrosion resistance.

- Welding Parameters: Optimize welding parameters (e.g., heat input, travel speed) to minimize distortion, cracking, and other defects.

- Post-Weld Treatment: Apply heat treatment or other post-weld processes to enhance the weld’s properties, such as strength and toughness.

2. What are the common welding defects and how do you prevent them?

Types of Welding Defects

- Porosity: Gas bubbles trapped in the weld metal.

- Cracking: Fractures in the weld metal or base metal.

- Incomplete Penetration: Lack of fusion between the weld metal and base metal.

- Undercut: Grooves melted into the base metal adjacent to the weld.

- Slag Inclusions: Non-metallic particles trapped in the weld metal.

Prevention Techniques

- Use clean welding materials and surfaces.

- Select appropriate welding parameters and techniques.

- Properly prepare the joint and use backing materials.

- Shield the weld from contaminants (e.g., oxygen, moisture).

- Perform post-weld inspections and repairs as necessary.

3. How do you ensure the quality of welded joints?

To ensure the quality of welded joints, several measures are taken:

- Welding Procedures: Establish and follow standardized welding procedures.

- Welder Certification: Qualify welders to demonstrate their skills and knowledge.

- Inspection and Testing: Perform visual inspections, non-destructive testing (e.g., ultrasonic, radiography), and mechanical testing to verify weld quality.

- Quality Control: Implement a quality control system to monitor and improve welding processes.

- Continuous Improvement: Regularly review and update welding practices based on feedback and industry best practices.

4. Describe the safety precautions to be taken while welding?

Welding involves potential hazards, so safety precautions are paramount:

- Personal Protective Equipment: Wear protective clothing, helmet, gloves, and respiratory mask.

- Work Area Ventilation: Ensure adequate ventilation to remove fumes and gases.

- Fire Prevention: Clear the work area of flammable materials and have fire extinguishers nearby.

- Electrical Safety: Ground welding equipment properly and check for electrical hazards.

- Eye Protection: Use welding helmets with appropriate filters to protect eyes from harmful radiation.

5. How do you motivate and manage a team of fabricators?

Effective team management and motivation are crucial:

- Communication: Establish clear communication channels and provide regular updates.

- Delegation: Assign tasks and responsibilities based on skills and experience.

- Recognition: Acknowledge and reward contributions to boost morale.

- Training and Development: Provide opportunities for professional growth and skill enhancement.

- Feedback: Offer constructive feedback to improve performance and foster a positive work environment.

6. How do you handle conflicts within the fabrication team?

Conflict resolution is essential to maintain a harmonious work environment:

- Open Communication: Encourage open dialogue and provide a platform for team members to express concerns.

- Objectivity: Approach conflicts impartially and focus on finding solutions rather than assigning blame.

- Mediation: Facilitate discussions between conflicting parties to reach mutually acceptable outcomes.

- Documentation: Document conflicts and resolutions to prevent recurrence and provide a reference point.

- Follow-Up: Monitor the situation after resolving conflicts to ensure effective outcomes.

7. Describe your experience with lean manufacturing principles?

Lean manufacturing aims to eliminate waste and improve efficiency:

- Value Stream Mapping: Identify and analyze material and information flow to identify inefficiencies.

- 5S: Implement organization, orderliness, and cleanliness in the workplace.

- Kanban: Use visual signals to manage production flow and reduce overproduction.

- Single-Piece Flow: Produce items one at a time to minimize lead times and improve quality.

- Continuous Improvement: Foster a culture of ongoing improvement and innovation.

8. How do you ensure that fabrication processes meet customer requirements?

Customer satisfaction is paramount:

- Clear Specifications: Define and communicate customer requirements thoroughly.

- Process Control: Implement quality control measures to ensure consistency and adherence to specifications.

- Customer Feedback: Regularly gather feedback from customers to identify areas for improvement.

- Continuous Evaluation: Monitor and evaluate fabrication processes to identify and address any deviations from requirements.

- Corrective Action: Promptly implement corrective actions to address any non-conformances and prevent recurrence.

9. How do you manage inventory and minimize waste in the fabrication process?

Efficient inventory management is crucial:

- Inventory Control System: Implement a robust inventory control system to track materials and optimize stock levels.

- Just-in-Time Delivery: Coordinate with suppliers to deliver materials as needed, reducing waste due to overstocking.

- Material Repurposing: Explore ways to repurpose or recycle scrap materials to minimize waste.

- Regular Audits: Conduct regular inventory audits to identify obsolete or excess materials.

- Collaboration: Foster collaboration between departments to minimize material waste through effective communication and coordination.

10. How do you stay updated with the latest advancements in fabrication techniques?

Continuous learning is essential:

- Industry Events: Attend industry conferences, trade shows, and workshops to learn about new technologies.

- Technical Journals and Publications: Subscribe to industry publications and stay informed about advancements.

- Online Courses:Enroll in online courses or certifications to enhance knowledge and skills.

- Networking: Connect with professionals in the field to exchange ideas and learn about best practices.

- Innovation: Encourage innovation and experimentation within the fabrication team to drive continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fabrication Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fabrication Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fabrication Supervisors are responsible for overseeing the fabrication process, ensuring that products are manufactured according to specifications and within budget.

1. Plan and Schedule Fabrication

Develop and implement fabrication plans and schedules.

- Determine resource requirements, including materials, equipment, and labor.

- Coordinate with production planning and control to ensure timely delivery of materials and components.

2. Manage Fabrication Process

Supervise and direct fabrication activities, including cutting, welding, assembling, and finishing.

- Monitor progress and ensure adherence to quality standards.

- Troubleshoot and resolve production issues.

3. Ensure Safety and Compliance

Maintain a safe and compliant work environment.

- Enforce safety regulations and procedures.

- Conduct safety inspections and audits.

4. Manage Fabrication Team

Supervise and lead a team of fabricators.

- Provide training and development opportunities.

- Motivate and support team members.

Interview Tips

Preparing effectively for an interview can increase your chances of success. Here are some tips to help you ace your interview for a Fabrication Supervisor position:

1. Research the Company and Role

Familiarize yourself with the company’s website, industry news, and recent projects. This demonstrates your interest and helps you understand the company’s culture and goals.

- Read the job description carefully, noting the key responsibilities and qualifications.

- Identify specific examples from your experience that align with the job requirements.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses. Practice delivering your answers clearly and concisely.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific details.

- Consider behavioral questions that ask about your problem-solving skills, teamwork abilities, and handling of pressure.

3. Showcase Your Skills and Experience

Highlight your relevant skills and experience in your resume and during the interview. Quantify your accomplishments with specific metrics whenever possible.

- Emphasize your technical expertise in fabrication techniques, quality control, and safety.

- Provide examples of your leadership and management abilities, such as motivating teams and resolving conflicts.

4. Be Enthusiastic and Professional

Demonstrate your enthusiasm for the role and the company. Maintain a positive attitude and dress professionally.

- Be respectful of the interviewer’s time and respond to questions honestly and thoroughly.

- Ask thoughtful questions at the end of the interview to show your engagement and interest.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Fabrication Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.