Are you gearing up for an interview for a Grinding Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Grinding Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

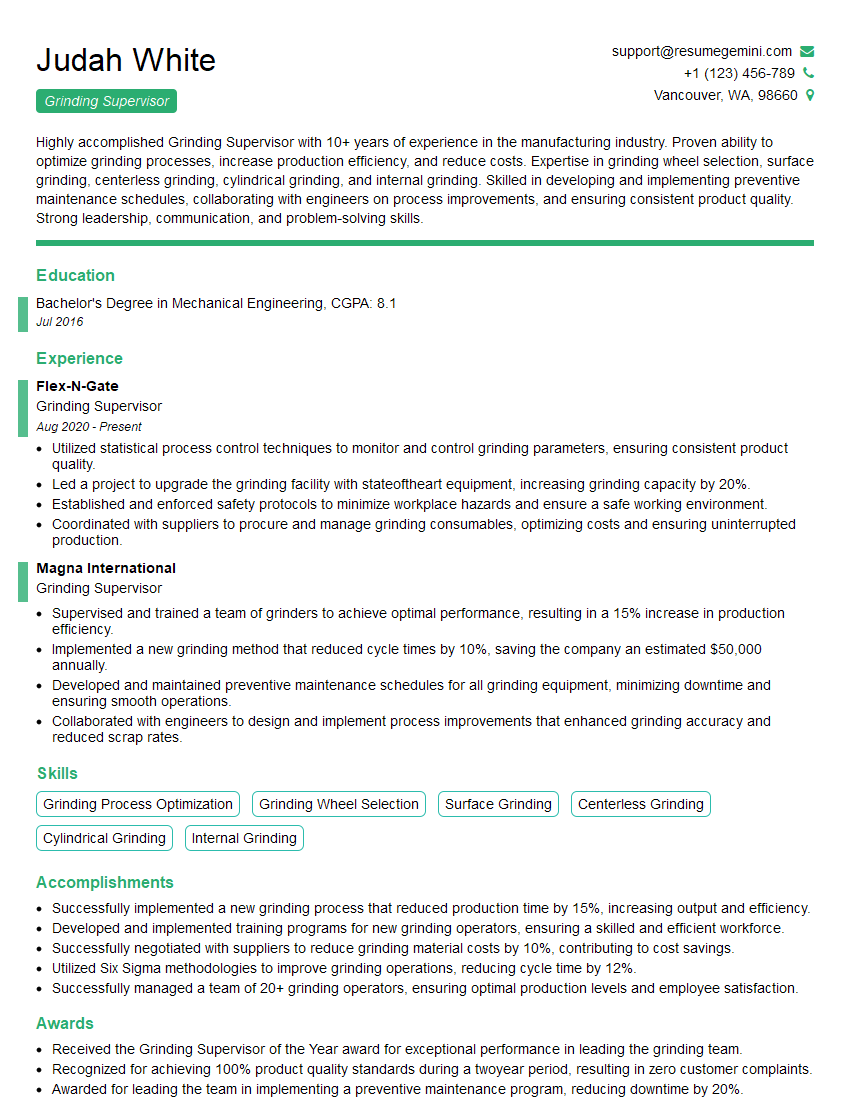

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grinding Supervisor

1. How do you ensure that the grinding process meets the required specifications and quality standards?

- Establish clear specifications and tolerances for the grinding process.

- Develop and implement inspection and testing procedures to monitor and control the quality of the ground materials.

- Calibrate and maintain grinding equipment regularly to ensure accuracy and precision.

- Provide operators with training and support to ensure they follow proper grinding techniques.

- Use statistical process control (SPC) techniques to analyze data and identify areas for improvement.

2. What are the common types of grinding machines used in industry and their respective applications?

Surface grinding machines

- Used to produce flat, smooth surfaces on various materials.

- Applications include: automotive parts, aerospace components, medical devices.

Cylindrical grinding machines

- Used to grind cylindrical surfaces, such as shafts, gears, and bearings.

- Applications include: heavy equipment, machine tools, automotive engines.

Centerless grinding machines

- Used to grind external and internal cylindrical surfaces without the use of centers.

- Applications include: automotive valves, medical needles, ball bearings.

3. How do you handle situations where the grinding process is not performing as expected?

- Identify the root cause of the problem through troubleshooting and analysis.

- Develop and implement corrective action plans to address the issue.

- Monitor the results of the corrective actions to ensure they are effective.

- Communicate with management and other stakeholders to keep them informed of the situation and any potential delays.

- Document the corrective actions and lessons learned for future reference.

4. What methods do you use to optimize the grinding process and improve efficiency?

- Optimize grinding wheel selection and dressing techniques to maximize grinding performance.

- Establish optimal cutting parameters (speed, feed, depth) based on material properties and grinding requirements.

- Implement automated systems to reduce setup times and improve production flow.

- Conduct regular maintenance and calibration of grinding equipment to prevent breakdowns and ensure accuracy.

- Monitor and analyze grinding data using SPC techniques to identify areas for improvement.

5. How do you ensure the safety of operators and maintain a safe work environment in the grinding area?

- Establish and enforce safety protocols and procedures for all grinding operations.

- Provide operators with proper personal protective equipment (PPE) and ensure its correct use.

- Maintain a clean and organized work area to minimize hazards and slips/falls.

- Provide adequate ventilation to remove dust and fumes generated during grinding.

- Train operators on proper grinding techniques and emergency procedures.

6. How do you stay updated on the latest advancements and best practices in grinding technology?

- Attend industry conferences, workshops, and seminars.

- Read technical journals and publications related to grinding.

- Consult with grinding equipment manufacturers and suppliers.

- Participate in online forums and discussion groups.

- Network with other grinding professionals to exchange knowledge and experiences.

7. How do you motivate and lead a team of grinding operators to achieve high performance?

- Establish clear performance goals and expectations for the team.

- Provide regular feedback and recognition to acknowledge and reward good performance.

- Empower operators to take ownership of their work and contribute ideas for improvement.

- Foster a positive and collaborative work environment where operators feel valued and respected.

- Lead by example and demonstrate a commitment to safety, quality, and continuous improvement.

8. What is your approach to training and developing grinding operators?

- Identify training needs based on job requirements and performance gaps.

- Develop and deliver training programs that cover both technical and safety aspects of grinding.

- Provide hands-on training and supervised practice to reinforce learning.

- Monitor operator progress and provide additional support as needed.

- Encourage operators to seek continuous improvement opportunities through certification programs or workshops.

9. How do you manage inventory and minimize downtime in the grinding area?

- Implement an inventory management system to track grinding wheels, abrasives, and other materials.

- Establish minimum inventory levels and reorder points to prevent shortages.

- Work with suppliers to secure timely delivery of materials.

- Maintain backup equipment to minimize downtime in case of breakdowns.

- Train operators on basic maintenance and troubleshooting to reduce the need for external repairs.

10. How do you measure and evaluate the effectiveness of your grinding operations?

- Track key performance indicators (KPIs) such as production output, quality rejects, and machine uptime.

- Compare actual performance to established targets and identify areas for improvement.

- Conduct regular audits to assess compliance with safety procedures and quality standards.

- Seek feedback from customers and internal stakeholders to gather insights into the effectiveness of the grinding process.

- Use data analysis techniques to identify trends, patterns, and opportunities for optimization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grinding Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grinding Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grinding Supervisors play a pivotal role in the smooth functioning of grinding operations within a manufacturing facility. Their responsibilities encompass a wide range of tasks that ensure the efficient production of high-quality ground materials.

1. Production Management

Supervisors oversee the production process, ensuring that grinding machines are operating optimally to meet production targets. They monitor machine performance, adjust settings, and troubleshoot issues to maximize efficiency and minimize downtime.

- Plan and schedule grinding operations, optimizing machine utilization and workflow

- Monitor machine performance, including cycle times, tool wear, and grinding quality

- Adjust machine settings and parameters to optimize grinding efficiency, reduce scrap, and improve product quality

2. Quality Control

Grinding Supervisors ensure the quality of ground materials by establishing and maintaining quality standards. They inspect finished products, monitor grinding processes, and implement quality control measures to prevent defects and ensure compliance with specifications.

- Establish and implement quality control standards for ground products

- Conduct regular inspections of ground materials and grinding processes to ensure compliance with specifications

- Identify and resolve quality issues, implementing corrective actions to improve grinding processes

3. Team Management

Supervisors lead and motivate a team of grinding operators, providing guidance, training, and support. They create a positive work environment, fostering collaboration and teamwork to achieve production goals.

- Lead and motivate a team of grinding operators, assigning tasks, providing training, and evaluating performance

- Create a positive and supportive work environment, promoting teamwork and collaboration

- Establish and enforce safety protocols, ensuring a safe working environment for all team members

4. Maintenance and Equipment Management

Grinding Supervisors maintain grinding equipment, ensuring it is in good working condition and operating at peak performance. They perform routine maintenance tasks, troubleshoot problems, and coordinate repairs to minimize downtime.

- Perform routine maintenance and inspection of grinding equipment, ensuring it is in good working condition

- Troubleshoot and resolve equipment problems, coordinating repairs and replacements as needed

- Monitor and control grinding tool inventory, ensuring availability of necessary tools

Interview Tips

Preparing for an interview for a Grinding Supervisor position requires thorough knowledge of the job responsibilities and industry-specific skills. Here are some tips to help candidates excel in the interview:

1. Research the Company and Industry

Before the interview, candidates should thoroughly research the company and the grinding industry. This will help them understand the company’s culture, values, and specific grinding processes used. Knowledge of industry trends and advancements will also demonstrate a proactive approach.

2. Highlight Relevant Experience

Candidates should emphasize their experience in grinding operations, particularly in areas related to production management, quality control, team leadership, and equipment maintenance. Providing specific examples and quantifying accomplishments will add credibility to their claims.

3. Demonstrate Problem-Solving Skills

Grinding Supervisors often encounter unexpected challenges in the workplace. Candidates should prepare to discuss their problem-solving abilities, explaining how they have successfully resolved issues related to machine performance, quality defects, or team dynamics.

4. Prepare for Technical Questions

Interviewers may ask technical questions about grinding processes, machine operation, and quality control techniques. Candidates should review grinding principles, machine settings, and quality standards to answer these questions confidently.

5. Show Enthusiasm and Professionalism

Candidates should convey their enthusiasm for the position and the grinding industry. They should dress professionally, maintain eye contact, and ask insightful questions to demonstrate their interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grinding Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!