Are you gearing up for an interview for a Head Sulfide Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Head Sulfide Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

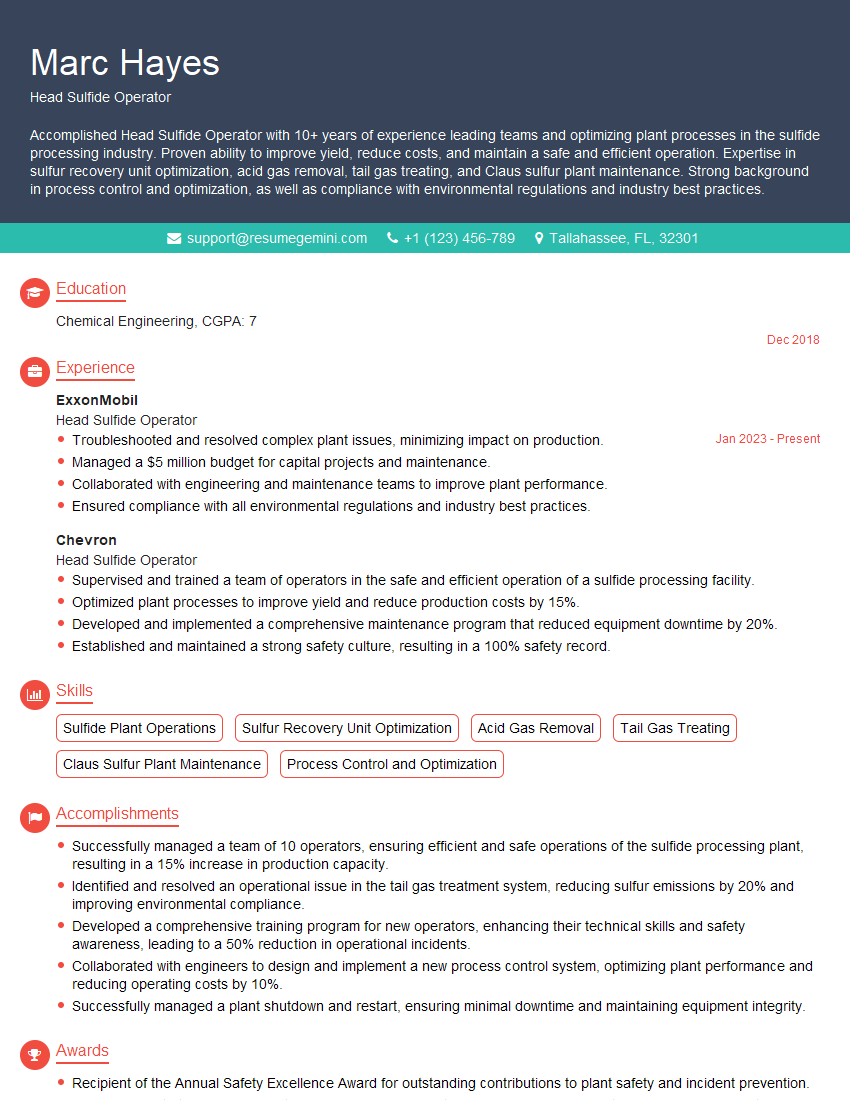

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Head Sulfide Operator

1. What are the key responsibilities of a Head Sulfide Operator?

As a Head Sulfide Operator, I would be responsible for:

- Leading and supervising a team of sulfide operators

- Monitoring and controlling the sulfide production process

- Ensuring that the sulfide production meets the required quality standards

- Troubleshooting and resolving any problems that may arise during the production process

- Maintaining a safe and efficient work environment

2. What are the different types of sulfide production processes?

Claus Process

- Uses thermal decomposition to convert hydrogen sulfide (H2S) to elemental sulfur

- Involves burning H2S with a controlled amount of air in a reaction furnace

Stretford Process

- Uses an aqueous solution of sodium carbonate and anthraquinone disulfonate to absorb H2S

- H2S is oxidized to elemental sulfur, which is then separated from the solution

3. What are the key factors that affect the efficiency of a sulfide production process?

- Temperature

- Pressure

- Residence time

- Concentration of H2S in the feed gas

- Type of catalyst used

4. What are the safety hazards associated with working in a sulfide production plant?

- Exposure to H2S gas, which can be toxic and corrosive

- Exposure to sulfur dioxide (SO2) gas, which can irritate the respiratory system

- Exposure to other hazardous chemicals, such as ammonia and chlorine

- Fire and explosion hazards

- Slip and fall hazards

5. What are the environmental regulations that apply to sulfide production plants?

- The Clean Air Act

- The Clean Water Act

- The Resource Conservation and Recovery Act

- The Occupational Safety and Health Act

6. What are the key maintenance tasks that are required for a sulfide production plant?

- Regular inspection and cleaning of equipment

- Replacement of worn or damaged parts

- Calibration of instruments

- Lubrication of moving parts

- Preventive maintenance

7. What are the different types of training that are required for sulfide operators?

- Safety training

- Process training

- Equipment training

- Environmental training

8. What are the career advancement opportunities for sulfide operators?

- Supervisor

- Manager

- Process engineer

- Environmental engineer

- Safety engineer

9. What are the key skills and qualities that are required for success as a sulfide operator?

- Strong technical skills

- Excellent communication skills

- Ability to work independently and as part of a team

- Strong work ethic

- Commitment to safety

10. What are the future trends in the sulfide production industry?

- Increased demand for sulfur

- Development of more efficient and environmentally friendly production processes

- Increased use of sulfur in renewable energy applications

- Continued focus on safety and environmental protection

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Head Sulfide Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Head Sulfide Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Head Sulfide Operator plays a vital role in the organization, overseeing all aspects of the sulfide operation. Their responsibilities encompass a wide range of duties, ensuring the smooth functioning and efficiency of the plant.

1. Operational Management

Directs and coordinates the activities of the sulfide operating team, assigning tasks and responsibilities to optimize production and efficiency.

- Schedules and assigns shifts to ensure adequate staffing levels and avoid disruptions.

- Ensures compliance with all safety regulations and environmental standards, minimizing risks and maintaining a safe work environment.

2. Process Monitoring and Control

Continuously monitors and adjusts process parameters to optimize the production of sulfide and minimize waste.

- Interprets data from sensors and instruments to identify and address any deviations from the desired operating conditions.

- Troubleshoots and resolves process issues to ensure uninterrupted operation and maintain production targets.

3. Equipment Maintenance and Inspection

Supervises the maintenance and repair of all equipment within the sulfide operation, ensuring optimal performance and preventing breakdowns.

- Conducts regular inspections and schedules preventive maintenance to minimize potential equipment failures.

- Coordinates with maintenance personnel to ensure timely repairs and minimize downtime.

4. Production Reporting and Optimization

Tracks and records production data, identifying trends and areas for improvement.

- Prepares reports and presentations on sulfide production and performance metrics for management and stakeholders.

- Analyzes data to identify opportunities for process optimization and increase efficiency.

Interview Tips

Preparing for an interview for the position of Head Sulfide Operator requires a combination of technical knowledge and soft skills. Here are some effective tips to help candidates ace the interview:

1. Research the Company and Position

Candidates should thoroughly research the company and the specific role to gain a deep understanding of the organization’s goals, culture, and the responsibilities of the Head Sulfide Operator.

- Visit the company website to learn about its history, products, and services.

- Review industry publications and news articles to stay informed about the latest trends and advancements in sulfide production.

2. Highlight Relevant Experience and Skills

Candidates should tailor their resume and interview responses to emphasize their relevant experience and skills that align with the job requirements.

- Quantify accomplishments whenever possible, using specific metrics to demonstrate the impact of their work.

- Practice describing their experience and skills using the STAR method (Situation, Task, Action, Result).

3. Prepare for Technical Questions

Interviewers will likely ask technical questions to assess the candidate’s knowledge and understanding of sulfide production processes and equipment.

- Review the basics of sulfide production, including the chemical reactions and process control principles.

- Be prepared to discuss their experience with specific equipment used in sulfide operations, such as reactors, scrubbers, and instrumentation.

4. Demonstrate Leadership and Management Skills

The Head Sulfide Operator is a leadership role, so candidates should be prepared to highlight their leadership and management style.

- Describe their experience in motivating and leading teams, and their ability to resolve conflicts and build consensus.

- Discuss their approach to performance management and their strategies for developing and mentoring team members.

5. Be Confident and Enthusiastic

Interviewers are looking for candidates who are confident in their abilities and enthusiastic about the role. Candidates should maintain eye contact, speak clearly, and convey a positive attitude throughout the interview.

- Practice answering questions aloud to build confidence and fluency.

- Prepare questions to ask the interviewer, which demonstrates interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Head Sulfide Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.