Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hot Dip Plating Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

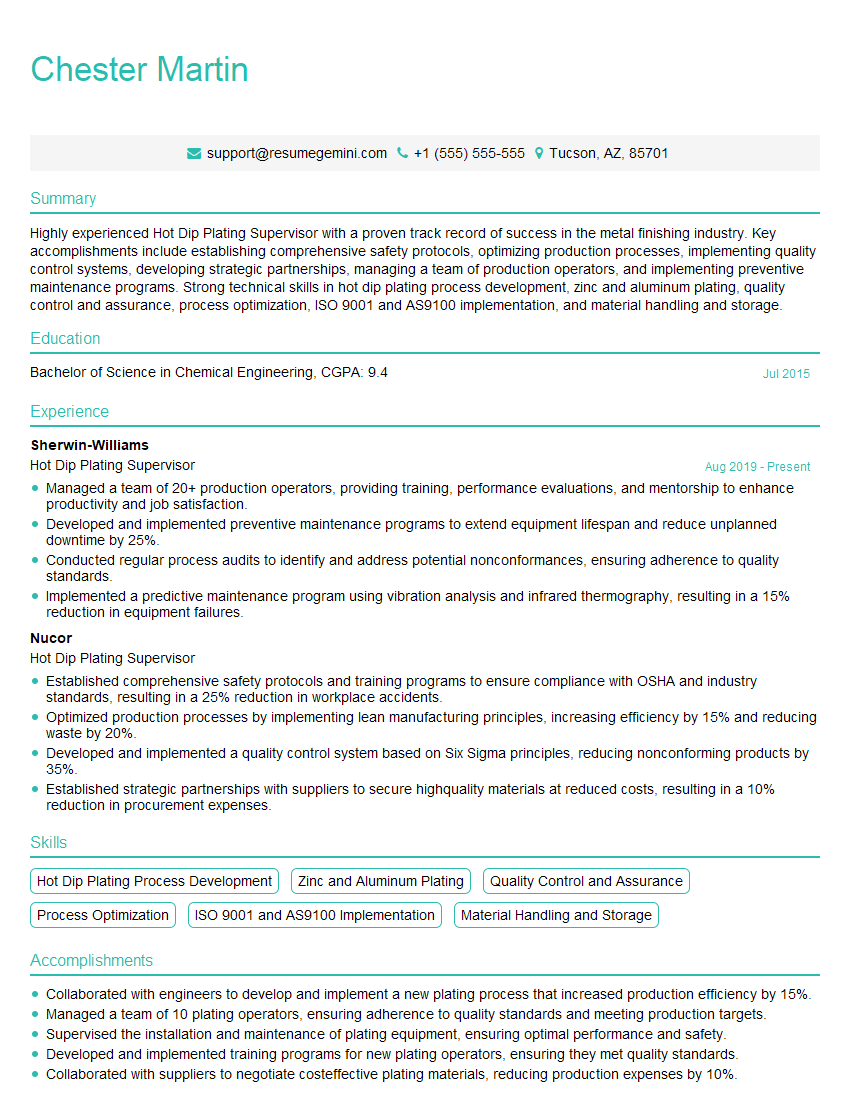

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Dip Plating Supervisor

1. Describe the process of Hot Dip Plating?

Hot Dip Plating is a metal coating process in which a metal is coated with a thin layer of a different metal by dipping the metal into a molten bath of the coating metal. The process involves the following steps:

- Surface preparation: The metal to be coated is cleaned and prepared to ensure a good bond between the coating and the base metal.

- Fluxing: The metal is dipped into a flux solution to remove any oxides or impurities from the surface.

- Dipping: The metal is dipped into a molten bath of the coating metal. The coating metal adheres to the base metal, forming a thin layer.

- Cooling: The coated metal is cooled to room temperature.

2. What are the advantages and disadvantages of Hot Dip Plating?

Advantages

- Excellent corrosion resistance

- Long service life

- Uniform coating thickness

- Cost-effective

Disadvantages

- Can be limited to certain metals

- May require additional treatments to improve adhesion

- Can be hazardous if not handled properly

3. What are the key factors to consider when selecting a Hot Dip Plating process?

- The metal to be coated

- The desired coating thickness

- The corrosion resistance required

- The cost of the process

4. What are the common defects associated with Hot Dip Plating?

- Blisters

- Peeling

- Cracking

- Discoloration

5. How do you ensure the quality of Hot Dip Plated products?

- Visual inspection

- Thickness testing

- Corrosion testing

- Adhesion testing

6. What are the safety precautions that need to be taken when working with Hot Dip Plating processes?

- Wear appropriate personal protective equipment (PPE)

- Handle molten metals with care

- Ensure proper ventilation

- Follow established safety protocols

7. What are the emerging trends in Hot Dip Plating technology?

- The use of new coating materials

- The development of more environmentally friendly processes

- The automation of Hot Dip Plating lines

8. How do you stay up-to-date with the latest developments in Hot Dip Plating?

- Attend industry conferences and trade shows

- Read technical journals and articles

- Network with other professionals in the field

9. What is your experience in managing a Hot Dip Plating operation?

- I have been managing a Hot Dip Plating operation for the past 5 years.

- I am responsible for all aspects of the operation, including production, quality control, and safety.

- I have a proven track record of meeting and exceeding production targets while maintaining high quality standards.

10. What are your strengths and weaknesses as a Hot Dip Plating Supervisor?

Strengths

- Strong technical knowledge of Hot Dip Plating processes

- Excellent problem-solving skills

- Proven ability to lead and motivate a team

Weaknesses

- I am sometimes too detail-oriented

- I can be impatient at times

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Dip Plating Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Dip Plating Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Hot Dip Plating Supervisor holds a crucial role in ensuring the efficient operation of a hot dip plating facility. The key responsibilities of this position encompass:

1. Production Supervision

Overseeing the entire plating process, including employee guidance, production monitoring, and quality control

- Leading and motivating a team of plating operators and related personnel

- Establishing and maintaining high standards of production efficiency and product quality

- Ensuring compliance with all applicable safety and environmental regulations

2. Process Optimization

Continuously improving and optimizing plating processes to enhance efficiency and minimize waste

- Identifying and addressing bottlenecks in the production process

- Implementing process improvements based on data analysis and industry best practices

- Collaborating with engineers and technicians to develop new or improved plating techniques

3. Equipment Maintenance

Ensuring the proper functioning and maintenance of all plating equipment and machinery

- Conducting regular inspections and preventative maintenance on equipment

- Identifying and troubleshooting equipment malfunctions promptly

- Working closely with maintenance personnel to resolve equipment issues and minimize downtime

4. Inventory Management

Managing the inventory of raw materials, chemicals, and consumables used in the plating process

- Maintaining accurate inventory records and forecasting future needs

- Coordinating with suppliers to ensure timely delivery of materials

- Minimizing waste and maximizing material utilization

Interview Tips

To ace your interview for the Hot Dip Plating Supervisor position, here are some crucial tips:

1. Research the Company and Industry

Gather information about the company’s history, products or services, and industry trends. This demonstrates your interest and enthusiasm for the role.

- Study the company’s website, annual reports, and industry publications

- Identify the company’s key competitors and market position

2. Practice Your Answers

Prepare for common interview questions by rehearsing your responses aloud. This will boost your confidence and ensure you articulate your skills and experience clearly.

- Read up on common interview questions related to hot dip plating

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

3. Showcase Your Technical Expertise

Highlight your in-depth knowledge of hot dip plating processes, techniques, and equipment. Use specific examples to demonstrate your technical proficiency.

- Discuss your experience with different plating metals and alloys

- Explain the principles of surface preparation, cleaning, and post-treatment

4. Emphasize Your Leadership Abilities

Hot Dip Plating Supervisors are responsible for leading and motivating a team. Share examples of your leadership style, conflict resolution skills, and ability to inspire and empower others.

- Describe how you handle challenging situations and manage team dynamics

- Provide specific instances where you successfully led teams to achieve production targets

5. Dress Professionally and Arrive Prepared

Present yourself professionally, both in terms of attire and punctuality. Arrive on time for the interview and bring any necessary documents or portfolio.

- Wear business formal or business casual attire

- Bring a copy of your resume, references, and any relevant certifications

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hot Dip Plating Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!