Are you gearing up for an interview for a Loading Rack Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Loading Rack Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

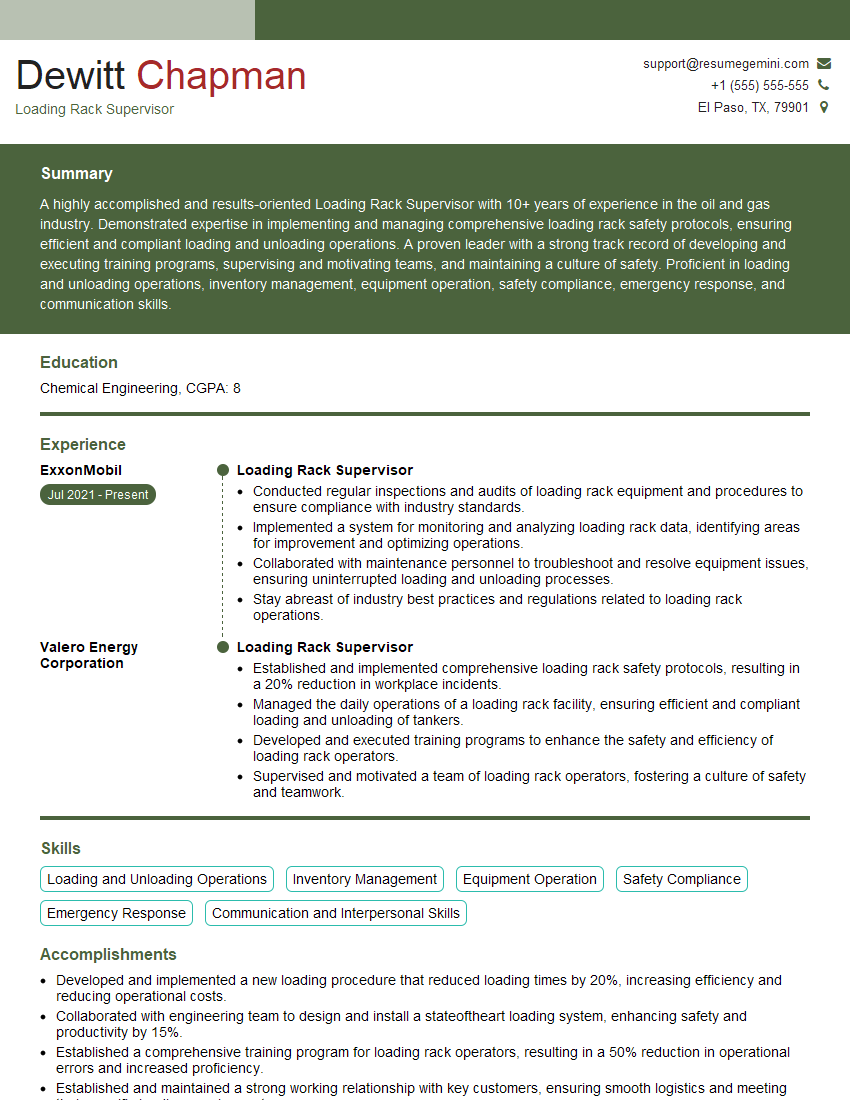

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Loading Rack Supervisor

1. What are the key technical skills and responsibilities of a Loading Rack Supervisor?

As a Loading Rack Supervisor, I am responsible for overseeing all aspects of the loading rack operations, ensuring the safe and efficient transfer of hazardous and non-hazardous materials. My key technical skills include:

- In-depth knowledge of loading rack equipment and processes, including pumps, valves, hoses, and safety systems.

- Expertise in hazardous materials handling and transportation regulations, including IMDG, ADR, and DOT.

- Proficient in monitoring and controlling loading operations, adhering to quality standards and industry best practices.

- Ability to troubleshoot and resolve technical issues related to loading equipment and material compatibility.

- Excellent communication and interpersonal skills for interacting with drivers, operators, and other stakeholders.

2. How do you ensure that loading operations comply with all applicable safety regulations and industry standards?

: Risk Assessment and Control

- Conduct thorough risk assessments to identify potential hazards and implement appropriate control measures.

- Establish and enforce clear loading procedures and work instructions, ensuring compliance with safety guidelines.

- Provide regular training and supervision to operators, emphasizing the importance of adherence to safety protocols.

Subheading: Monitoring and Auditing

- Continuously monitor loading operations for any deviations from established standards and procedures.

- Conduct regular audits of loading equipment and documentation to ensure compliance with regulatory requirements.

- Investigate any incidents or near-misses, implementing corrective actions to prevent future occurrences.

3. Describe your experience in managing and supervising a team of loading rack operators.

In my previous role as Loading Rack Supervisor, I effectively managed a team of 15 operators responsible for loading various petroleum products onto tanker trucks. My responsibilities included:

- Providing clear instructions, training, and performance feedback to ensure efficient and safe loading operations.

- Motivating and empowering the team to achieve performance targets and maintain a positive work environment.

- Handling any conflicts or issues within the team, fostering a collaborative and respectful workplace.

- Maintaining open communication channels, ensuring that all team members are aware of changes and updates.

4. How do you prioritize and manage multiple loading operations simultaneously, ensuring timely and accurate product delivery?

Effective prioritization and management of multiple loading operations are crucial to meeting delivery deadlines and avoiding delays. I utilize the following strategies:

- Establish clear loading schedules and sequencing to optimize the utilization of loading resources.

- Communicate loading priorities and deadlines to the team, ensuring alignment and efficient execution.

- Monitor the progress of each loading operation, adjusting schedules as needed to accommodate unforeseen delays.

- Collaborate with drivers and customers to provide accurate ETAs and manage expectations.

5. How do you ensure the compatibility of materials being loaded and the suitability of loading equipment for the specific products?

Ensuring material compatibility and equipment suitability is paramount for safe and effective loading operations. I follow these key steps:

- Thoroughly review product specifications and safety data sheets (SDS) to identify any potential incompatibilities.

- Verify that the loading equipment, hoses, gaskets, and seals are compatible with the materials being loaded.

- Conduct regular inspections of equipment to ensure it is in good working condition and meets industry standards.

- Train operators on the proper handling and storage of different materials to minimize risks.

6. Describe your experience in conducting quality assurance checks on loaded products, ensuring they meet the required specifications.

As part of my quality assurance responsibilities, I perform rigorous checks on loaded products to guarantee their compliance with specifications and customer requirements. My approach involves:

- Sampling and testing products in accordance with established protocols and standards.

- Reviewing documentation, including bills of lading and product certificates, to verify product characteristics.

- Calibrating and maintaining testing equipment to ensure accurate and reliable results.

- Working closely with quality control personnel to investigate any deviations from specifications and implement corrective actions.

7. How do you handle emergency situations and respond to incidents involving spills or leaks during loading operations?

In the event of an emergency, I am trained and equipped to respond swiftly and effectively to minimize risks and ensure the safety of personnel and the environment. My approach includes:

- Immediately activating the emergency response plan, alerting relevant personnel and authorities.

- Assessing the situation, identifying the source of the spill or leak, and isolating the affected area.

- Deploying appropriate containment measures, such as absorbent materials and spill kits, to minimize the spread of hazardous materials.

- Coordinating with emergency responders and cleanup crews to ensure a safe and efficient resolution.

8. Describe your experience in implementing continuous improvement initiatives to enhance the efficiency and safety of loading operations.

Continuous improvement is vital for optimizing loading operations. I actively seek opportunities to enhance efficiency and safety through the following initiatives:

- Regularly reviewing loading procedures and identifying areas for improvement.

- Consulting with operators and other stakeholders to gather feedback and suggestions.

- Evaluating new technologies and equipment that can enhance safety and productivity.

- Implementing training programs to improve operator skills and knowledge.

9. How do you motivate and engage your team to maintain a high level of productivity and safety awareness?

Motivating and engaging the team is crucial for maintaining a productive and safe work environment. I utilize the following strategies:

- Setting clear performance goals and providing regular feedback to encourage continuous improvement.

- Recognizing and rewarding employees for their contributions and achievements.

- Fostering a positive and inclusive work culture that values teamwork and collaboration.

- Empowering employees to take ownership of their roles and contribute to decision-making.

10. Describe your understanding of the latest industry trends and technological advancements related to loading rack operations.

To stay abreast of industry developments, I actively engage in the following activities:

- Attending industry conferences and workshops.

- Reading industry publications and technical journals.

- Networking with peers and experts in the field.

- Exploring emerging technologies that have the potential to improve safety and efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Loading Rack Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Loading Rack Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Loading Rack Supervisor is responsible for the safe and efficient operation of the loading rack. This includes:1. Overseeing the loading and unloading of products

The Loading Rack Supervisor is responsible for ensuring that all products are loaded and unloaded safely and efficiently. This includes:

- Scheduling and coordinating the loading and unloading of products.

- Ensuring that all products are loaded and unloaded in accordance with safety regulations.

- Monitoring the loading and unloading process to ensure that it is completed safely and efficiently.

2. Maintaining the loading rack

The Loading Rack Supervisor is responsible for maintaining the loading rack in a safe and efficient operating condition. This includes:

- Inspecting the loading rack regularly for any signs of damage or wear.

- Repairing or replacing any damaged or worn components.

- Keeping the loading rack clean and free of debris.

3. Training and supervising employees

The Loading Rack Supervisor is responsible for training and supervising employees who work on the loading rack. This includes:

- Training employees on the safe and efficient operation of the loading rack.

- Supervising employees to ensure that they are following safety regulations.

- Providing feedback to employees on their performance.

4. Enforcing safety regulations

The Loading Rack Supervisor is responsible for enforcing safety regulations on the loading rack. This includes:

- Ensuring that all employees are wearing appropriate safety gear.

- Ensuring that all equipment is being used safely.

- Investigating any safety incidents that occur on the loading rack.

Interview Tips

Here are some tips to help you ace your interview for a Loading Rack Supervisor position:1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience in loading rack operations. Be prepared to talk about your specific responsibilities and accomplishments in your previous roles. You can use the STAR method to answer questions about your experience. STAR stands for Situation, Task, Action, Result. When answering a question using the STAR method, start by describing the situation you were in, the task you were responsible for, the action you took, and the result of your actions.

4. Ask questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the job and the company culture. Some good questions to ask include:

- What are the biggest challenges facing the loading rack operation?

- What are the opportunities for advancement within the company?

- What is the company culture like?

5. Follow up after the interview

After the interview, send a thank-you note to the interviewer. In your thank-you note, reiterate your interest in the position and thank the interviewer for their time. You can also use the thank-you note to clarify any points that you may have missed during the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Loading Rack Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.