Are you gearing up for an interview for a Melt House Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Melt House Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

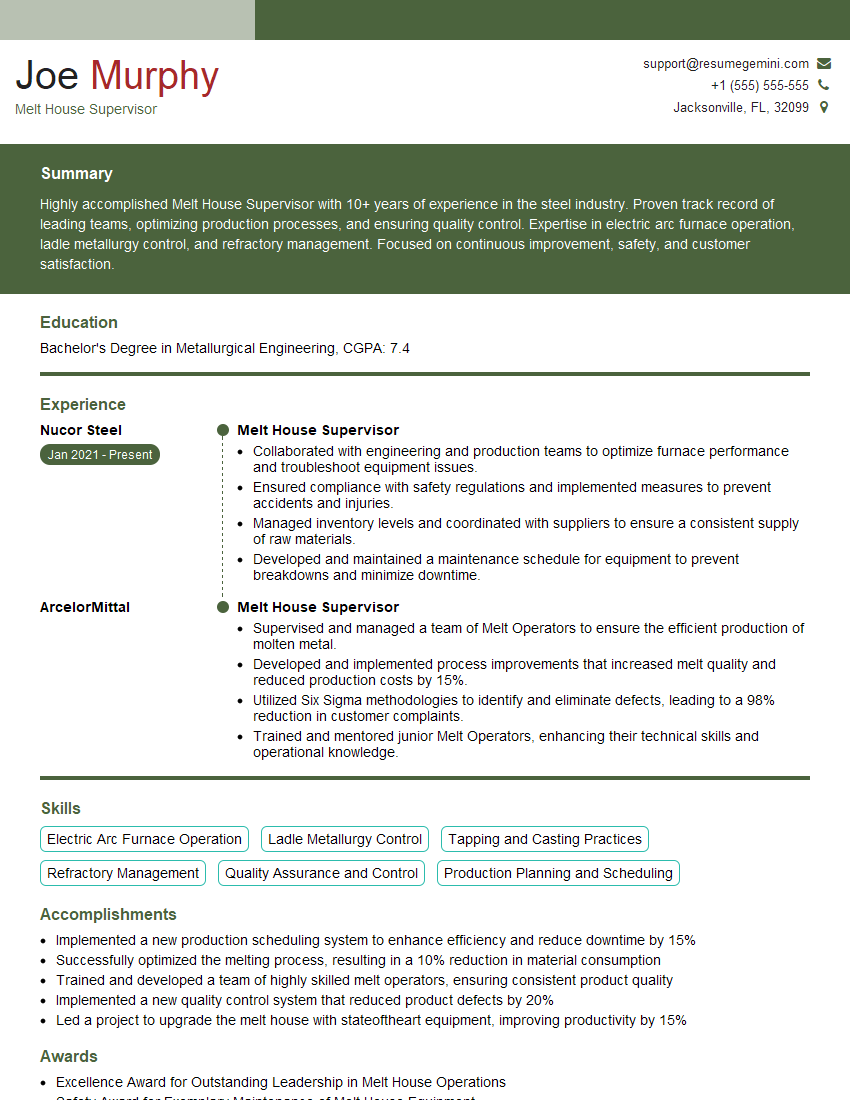

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Melt House Supervisor

1. Kindly explain the process of monitoring and controlling the melting operation?

The process of monitoring and controlling the melting operation involves:

- Regularly checking the temperature of the molten metal using pyrometers or thermocouples to ensure it’s within the specified range.

- Monitoring the flow rate of molten metal and adjusting the furnace settings accordingly.

- Observing the molten metal for any signs of contamination or impurities.

- Taking regular samples of the molten metal for chemical analysis to ensure it meets the desired specifications.

- Maintaining proper records of all monitoring and control activities.

2. Describe the safety measures you implement in the melt house?

To ensure the safety of personnel and equipment in the melt house, we implement the following measures:

Personal Protective Equipment (PPE):

- Providing and enforcing the use of appropriate PPE such as heat-resistant clothing, face shields, earplugs, and safety glasses.

Melt House Conditions:

- Maintaining a clean and organized work environment.

- Ensuring proper ventilation to control smoke and fumes.

- Inspecting equipment regularly and ensuring it’s in good working order.

- Establishing clear safety protocols and providing training to all personnel.

3. How do you handle a situation where the molten metal exceeds the desired temperature?

In the event the molten metal exceeds the desired temperature:

- I immediately notify the supervisor and other relevant personnel.

- I adjust the furnace settings to lower the temperature gradually.

- I monitor the temperature closely and take corrective actions as necessary.

- I investigate the cause of the temperature deviation and take steps to prevent it from recurring.

4. Explain how you coordinate with other departments within the organization?

To effectively coordinate with other departments, I:

- Regularly communicate with the production department to understand production schedules and adjust the melt house operations accordingly.

- Collaborate with the quality control department to ensure the molten metal meets the required specifications.

- Work with the maintenance department to maintain and repair equipment as needed.

- Participate in inter-departmental meetings to discuss safety, production, and operational issues.

5. Describe the quality control procedures you follow during the melting process?

To ensure the quality of the molten metal, I adhere to the following quality control procedures:

- Verifying the quality of the raw materials used in the melting process.

- Taking regular samples of the molten metal and analyzing them for chemical composition and physical properties.

- Monitoring the temperature and flow rate of the molten metal during the melting operation.

- Maintaining records of all quality control activities and reporting any deviations from the desired specifications.

6. What actions do you take to reduce energy consumption and improve efficiency in the melt house?

To reduce energy consumption and improve efficiency in the melt house, I:

- Implement energy-efficient melting practices, such as optimizing furnace settings and reducing idling time.

- Regularly inspect and maintain equipment to prevent energy losses.

- Monitor energy consumption and identify areas for improvement.

- Educate and train personnel on energy conservation practices.

7. Explain how you ensure the safety of personnel working in the melt house?

To ensure the safety of personnel working in the melt house, I:

- Enforce strict adherence to safety protocols and procedures.

- Conduct regular safety inspections and risk assessments.

- Provide comprehensive training to all personnel on safety hazards and emergency procedures.

- Promote a culture of safety awareness and encourage personnel to actively participate in safety initiatives.

8. Describe how you motivate and lead your team in the melt house?

To motivate and lead my team in the melt house, I:

- Set clear goals and expectations, and provide regular feedback.

- Recognize and reward achievements and contributions.

- Foster a positive and supportive work environment.

- Encourage team collaboration and problem-solving.

- Provide opportunities for professional development and growth.

9. Explain the importance of maintaining proper records and documentation in the melt house?

Maintaining proper records and documentation in the melt house is crucial for several reasons:

- It provides a detailed account of the melting process, including raw materials used, operating conditions, and quality control measures.

- It facilitates traceability of products and ensures compliance with industry regulations and standards.

- It serves as a valuable resource for troubleshooting and identifying areas for improvement.

- It provides evidence of due diligence and can be used in the event of any legal or regulatory inquiries.

10. Describe a recent project or initiative you led that improved the performance of the melt house?

In my previous role, I led a project to implement a new temperature control system in the melt house. The previous system was outdated and resulted in frequent temperature fluctuations, leading to quality issues and energy inefficiencies. The new system I implemented utilized advanced sensors and automation to precisely control the temperature of the molten metal. This resulted in improved product quality, reduced energy consumption, and increased productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Melt House Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Melt House Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Melt House Supervisor is responsible for managing the day-to-day operations of a melt house, which is a facility where metal is melted and refined. The Melt House Supervisor oversees a team of workers and is responsible for ensuring that the melt house operates safely and efficiently. Some of the key job responsibilities include:

1. Supervising a team of workers

The Melt House Supervisor is responsible for supervising a team of workers who operate the melt house equipment. The Supervisor must ensure that the workers are properly trained and that they are following all safety procedures. The Supervisor must also be able to motivate the workers and ensure that they are working together as a team.

2. Ensuring that the melt house operates safely and efficiently

The Melt House Supervisor is responsible for ensuring that the melt house operates safely and efficiently. The Supervisor must be familiar with all of the safety procedures and must be able to identify and correct any potential hazards. The Supervisor must also be able to develop and implement plans to improve the efficiency of the melt house operations.

3. Maintaining the melt house equipment

The Melt House Supervisor is responsible for maintaining the melt house equipment. The Supervisor must be able to identify and repair any problems with the equipment. The Supervisor must also be able to work with vendors to procure new equipment and parts.

4. Managing the melt house budget

The Melt House Supervisor is responsible for managing the melt house budget. The Supervisor must be able to track the melt house’s expenses and ensure that the budget is being met. The Supervisor must also be able to identify opportunities to save money.

Interview Tips

Here are some tips for candidates preparing for an interview for a Melt House Supervisor position:

1. Review the job description carefully

The job description will provide you with important information about the specific responsibilities of the Melt House Supervisor position. Make sure that you understand the key responsibilities and qualifications for the position.

2. Research the company

Researching the company will help you to understand the company’s culture and values. This will help you to answer questions about the company during the interview. You can research the company on the company’s website, social media pages, and news articles.

3. Practice answering common interview questions

There are a number of common interview questions that you may be asked during an interview for a Melt House Supervisor position. Some of the most common questions include:

- Tell me about your experience supervising a team of workers.

- What are your experience with ensuring that a work environment is operating safely and efficiently?

- What is your experience with maintaining and repairing equipment.

- What is your experience with managing a budget?

4. Be prepared to talk about your skills and experience

The interviewer will want to know about your skills and experience. Be prepared to talk about your experience in a clear and concise manner. You should also be prepared to provide examples of your work.

5. Dress professionally

The way you dress for an interview can make a big impression on the interviewer. Dress professionally and make sure that your clothes are clean and pressed.

6. Be confident

Being confident will help you to make a good impression on the interviewer. Make sure that you speak clearly and make eye contact with the interviewer. You should also be prepared to answer questions in a confident manner.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Melt House Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.