Are you gearing up for a career in Metal Cans Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Metal Cans Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

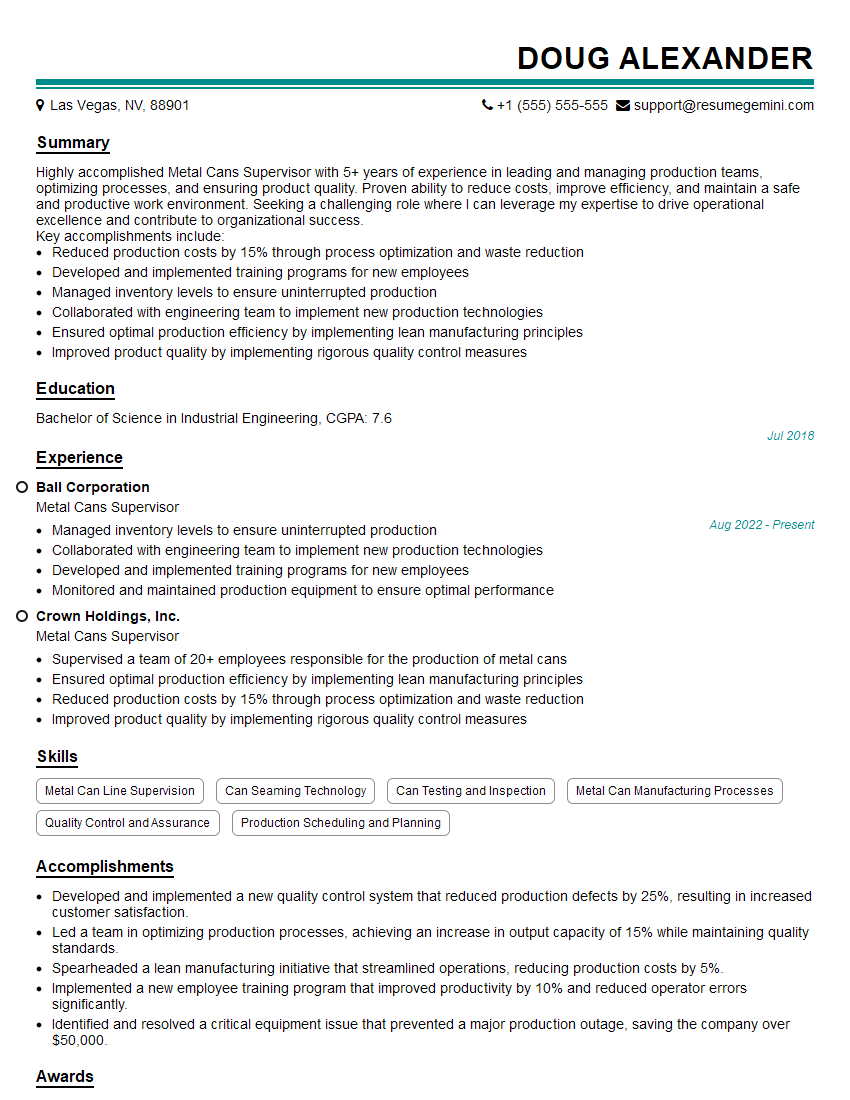

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Cans Supervisor

1. How would you ensure that the metal cans produced meet the required quality standards?

To ensure the quality of metal cans, I would implement a comprehensive quality control system that covers all stages of production. This system would include:

- Raw material inspection: Inspecting incoming raw materials to ensure they meet specifications.

- In-process inspections: Monitoring production processes at critical points to identify and correct any deviations from standards.

- Final product testing: Conducting rigorous testing on finished cans to verify their conformance with quality requirements.

- Statistical process control (SPC): Using SPC techniques to analyze production data and identify areas for improvement.

- Corrective and preventive action (CAPA): Implementing a CAPA system to address quality issues and prevent their recurrence.

2. What manufacturing processes are involved in the production of metal cans?

Raw Material Preparation

- Inspecting and preparing steel coils

- Cleaning and treating the coils to remove impurities

Can Forming

- Stamping and shaping the metal into the desired can shape

- Welding or seaming the can body

- Adding the can ends

Coating and Decoration

- Applying protective coatings to prevent corrosion

- Printing designs or labels on the cans

Quality Control and Inspection

- Inspecting cans throughout the manufacturing process

- Testing cans to ensure they meet quality standards

Packaging and Shipping

- Preparing cans for packaging

- Shipping cans to customers

3. How would you manage a team of production operators and ensure they are meeting performance targets?

To manage a team effectively and ensure performance targets are met, I would:

- Set clear expectations and goals: Communicate performance targets and expectations to the team clearly.

- Provide training and support: Ensure the team has the necessary training and resources to succeed.

- Monitor performance regularly: Track key performance indicators (KPIs) to assess progress towards targets.

- Provide feedback and coaching: Offer constructive feedback and coaching to help the team improve performance.

- Recognize and reward success: Acknowledge and reward team members for achieving or exceeding targets.

- Address performance issues promptly: If performance issues arise, address them promptly and collaboratively with the team.

4. What is your understanding of the safety protocols and regulations applicable to metal can manufacturing?

I am well-versed in the safety protocols and regulations applicable to metal can manufacturing, including:

- OSHA regulations: Occupational Safety and Health Administration (OSHA) regulations for general industry and specific hazards associated with metalworking.

- NFPA codes: National Fire Protection Association (NFPA) codes for fire prevention and protection.

- ANSI standards: American National Standards Institute (ANSI) standards for machinery safety and electrical safety.

- Company-specific safety policies and procedures: Specific safety guidelines and protocols established by the employer.

I am committed to maintaining a safe work environment and would ensure that all team members adhere to established safety protocols.

5. What are the key production metrics that you would track to measure the efficiency of the metal can production line?

- Production output: Number of cans produced per hour or shift.

- Quality yield: Percentage of cans that meet quality standards.

- Machine uptime: Percentage of time that production equipment is operational.

- Scrap rate: Percentage of raw materials or finished cans that are discarded due to defects.

- Labor efficiency: Ratio of production output to labor hours worked.

- Overall equipment effectiveness (OEE): Comprehensive measure of equipment performance that considers availability, performance, and quality.

6. How would you optimize the production process to reduce costs and increase productivity?

- Identify bottlenecks: Analyze the production process to identify areas where there are delays or inefficiencies.

- Improve equipment efficiency: Implement preventive maintenance programs and optimize equipment settings to minimize downtime and increase output.

- Reduce scrap rate: Identify and address the root causes of defects to minimize material waste and rework.

- Optimize labor allocation: Assign tasks to team members based on their skills and experience to improve efficiency.

- Implement continuous improvement initiatives: Regularly review production processes and identify areas for improvement through lean manufacturing techniques or Six Sigma.

7. What maintenance procedures are essential for ensuring the reliability and longevity of metal can production equipment?

- Regular inspections: Schedule routine inspections to identify potential issues early.

- Preventive maintenance: Perform scheduled maintenance tasks, such as lubrication, cleaning, and adjustments, to prevent failures.

- Predictive maintenance: Use condition monitoring techniques to identify and address potential issues before they cause downtime.

- Corrective maintenance: Promptly repair or replace equipment components that fail to prevent further damage or downtime.

- Training: Ensure that maintenance personnel are trained and qualified to perform maintenance tasks effectively.

8. How would you manage inventory levels of raw materials and finished goods to ensure optimal production and minimize waste?

- Establish inventory targets: Determine optimal inventory levels for raw materials and finished goods based on production schedules and demand forecasts.

- Implement inventory control systems: Use inventory management software or systems to track inventory levels and automate reordering.

- Monitor inventory levels regularly: Regularly review inventory levels and make adjustments as needed to prevent shortages or excess.

- Optimize ordering quantities: Calculate optimal ordering quantities to minimize inventory carrying costs while ensuring adequate supply.

- Reduce waste: Implement strategies such as first-in, first-out (FIFO) inventory management and quality inspections to minimize waste and spoilage.

9. What software or systems are you familiar with that are commonly used in metal can manufacturing?

- Manufacturing execution systems (MES): Software that manages and tracks production processes.

- Enterprise resource planning (ERP) systems: Software that integrates various business functions, including production planning and inventory management.

- Computer-aided design (CAD) software: Software used for designing metal can products.

- Statistical process control (SPC) software: Software used to analyze and monitor production data for quality control.

- Inventory management systems: Software used to track and manage inventory levels.

10. How would you stay up-to-date on the latest advancements and trends in the metal can manufacturing industry?

- Attend industry conferences and exhibitions: Participate in industry events to network and learn about new technologies and best practices.

- Read industry publications and trade journals: Stay informed about the latest news and trends through industry publications.

- Conduct research and development: Engage in ongoing research and development to identify opportunities for innovation and improvement.

- Collaborate with industry experts: Network with other professionals in the field to exchange ideas and share knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Cans Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Cans Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Cans Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!