Are you gearing up for an interview for a Mixing Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Mixing Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

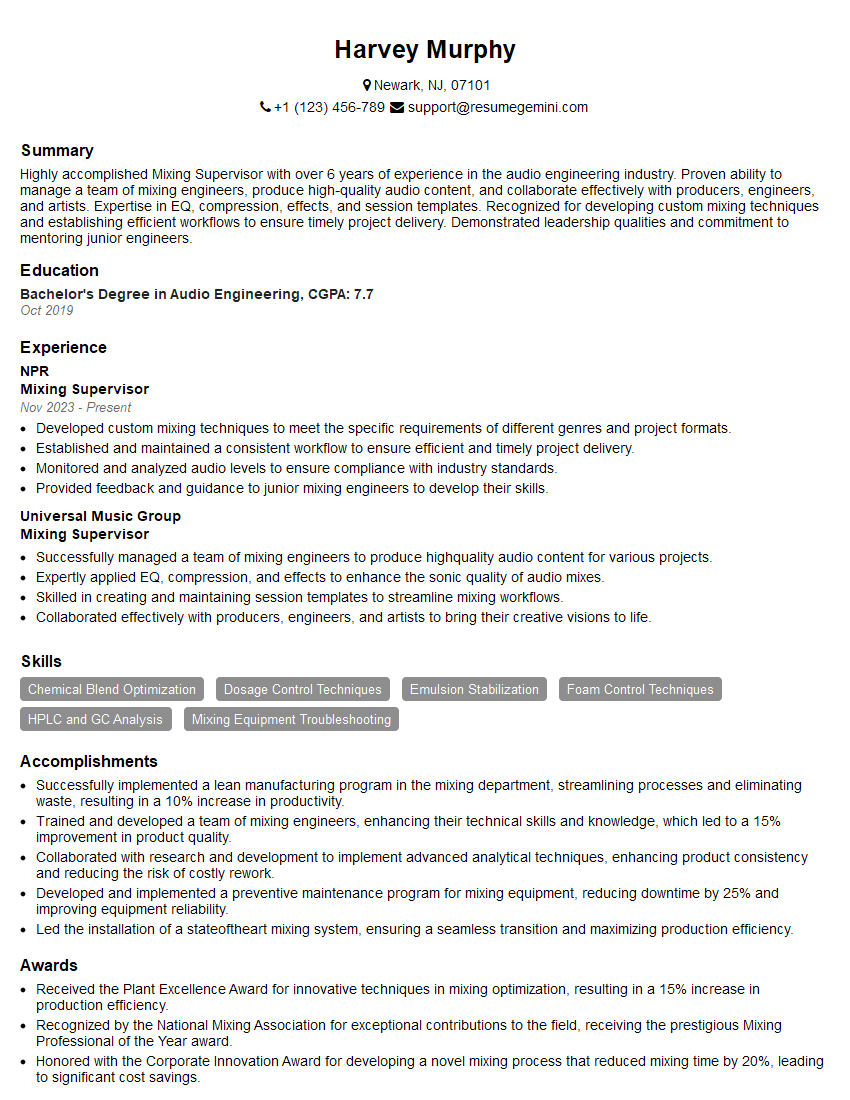

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mixing Supervisor

1. What are the key responsibilities of a Mixing Supervisor in a manufacturing setting?

- Plan, organize, and supervise the mixing of various materials to create products.

- Operate and maintain mixing equipment, ensuring optimal performance and efficiency.

2. Describe the steps involved in setting up and operating a mixer effectively.

Adhering to Specifications

- Review product specifications and determine appropriate mixing parameters.

- Calibrate equipment to ensure accurate measurements and prevent errors.

Ensuring Safety

- Follow safety protocols, wear protective gear, and ensure a safe work environment.

- Inspect equipment regularly for potential hazards and implement corrective actions.

3. How do you ensure the quality and consistency of mixed products?

- Establish mixing protocols and document procedures to maintain standards.

- Monitor mixing processes, taking samples for analysis and making adjustments as needed.

- Collaborate with quality control team to verify product specifications and identify areas for improvement.

4. How do you troubleshoot and resolve mixing-related issues that may arise during production?

- Identify the potential cause of the issue, considering factors such as equipment malfunction, incorrect ingredients, or process deviations.

- Analyze data, consult with technical experts, and implement corrective actions to resolve the problem.

- Document troubleshooting steps and implement preventive measures to minimize future occurrences.

5. What are the safety precautions that need to be followed while working with mixing equipment?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Ensure proper ventilation and exhaust systems are in place to prevent exposure to hazardous fumes or dust.

- Follow lockout-tagout procedures when servicing or cleaning equipment.

6. How do you manage a team of mixing operators and ensure their productivity and adherence to standards?

- Provide clear instructions, training, and support to team members.

- Monitor performance, offer feedback, and implement incentives to motivate and maintain productivity.

- Foster a positive and collaborative work environment that encourages teamwork and continuous improvement.

7. What are the different types of mixing equipment commonly used in manufacturing?

- Agitators: Used for blending liquids or slurries with low to moderate viscosity.

- Blenders: Designed to mix dry powders or granules with varying particle sizes.

- Mixers: Equipped with rotating blades or impellers for high-speed mixing and homogenization.

8. How do you optimize mixing processes to ensure efficiency and reduce waste?

- Analyze mixing parameters, such as speed, time, and temperature, to determine optimal settings.

- Utilize automated systems or instrumentation to control and monitor mixing processes precisely.

- Implement lean manufacturing techniques to minimize waste and improve overall productivity.

9. What are the latest advancements or trends in mixing technology that you are aware of?

- Advanced automation and data analytics for process optimization and quality control.

- Development of new mixing equipment with improved efficiency and reduced energy consumption.

- Research on nanomaterials and their applications in mixing processes.

10. How do you stay updated with the latest industry best practices and technological developments in the field of mixing?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Network with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mixing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mixing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Mixing Supervisor, you’ll be responsible for overseeing and optimizing the mixing process in a manufacturing environment. This will involve managing a team of operators, ensuring quality control, and troubleshooting any problems that may arise.

1. Managing Mixing Operations

You’ll be responsible for planning and scheduling mixing activities, as well as supervising operators and ensuring that they follow standard operating procedures. This will involve monitoring equipment performance, evaluating product quality, and taking corrective action when necessary.

2. Quality Control

You’ll be responsible for ensuring that the mixing process meets the required quality standards. This will involve conducting inspections, testing products, and maintaining records to document the quality of the products produced.

3. Troubleshooting and Problem-Solving

You’ll be the first line of defense when it comes to troubleshooting mixing problems. This will involve identifying the root cause of problems, developing corrective action plans, and implementing solutions to prevent recurrence.

4. Health and Safety

You’ll be responsible for ensuring that the mixing process is conducted in a safe and healthy manner. This will involve maintaining a clean and organized work area, following safety protocols, and providing training to operators.

Interview Tips

To ace your interview for a Mixing Supervisor position, it’s important to prepare by researching the company, practicing your answers to common interview questions, and dressing professionally.

1. Research the Company

Learn as much as you can about the company’s products, services, culture, and values. This will help you to understand the role of the Mixing Supervisor within the company and to tailor your answers to the interviewer’s questions.

2. Practice Your Answers

Take some time to think about common interview questions and prepare your answers in advance. This will help you to speak confidently and clearly during the interview.

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing a suit or business casual attire, and making sure that your clothes are clean and pressed.

Example Interview Questions and Answers

Here are some examples of interview questions that you may be asked, along with tips on how to answer them:

Question: Tell me about your experience in managing a team of operators. Answer:- In my previous role as Mixing Supervisor, I was responsible for managing a team of 10 operators. I developed and implemented training programs to ensure that my operators were well-trained and competent in their roles.

- I also established a system for monitoring operator performance and providing feedback, which helped to improve productivity and quality.

- To ensure quality control in a mixing process, I conduct inspections of incoming raw materials and finished products.

- I also maintain records of all mixing activities, including the equipment used, the process parameters, and the results of the inspections.

- This documentation helps me to track the quality of the products produced and to identify any potential problems.

- In my previous role, I was responsible for troubleshooting mixing problems on a daily basis.

- I have experience in identifying the root cause of problems, developing corrective action plans, and implementing solutions to prevent recurrence.

- For example, I once identified a problem with the mixing equipment that was causing the products to be under-mixed. I worked with the maintenance team to repair the equipment and to develop a new mixing procedure to prevent the problem from recurring.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mixing Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!