Are you gearing up for an interview for a Mold Making Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Mold Making Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

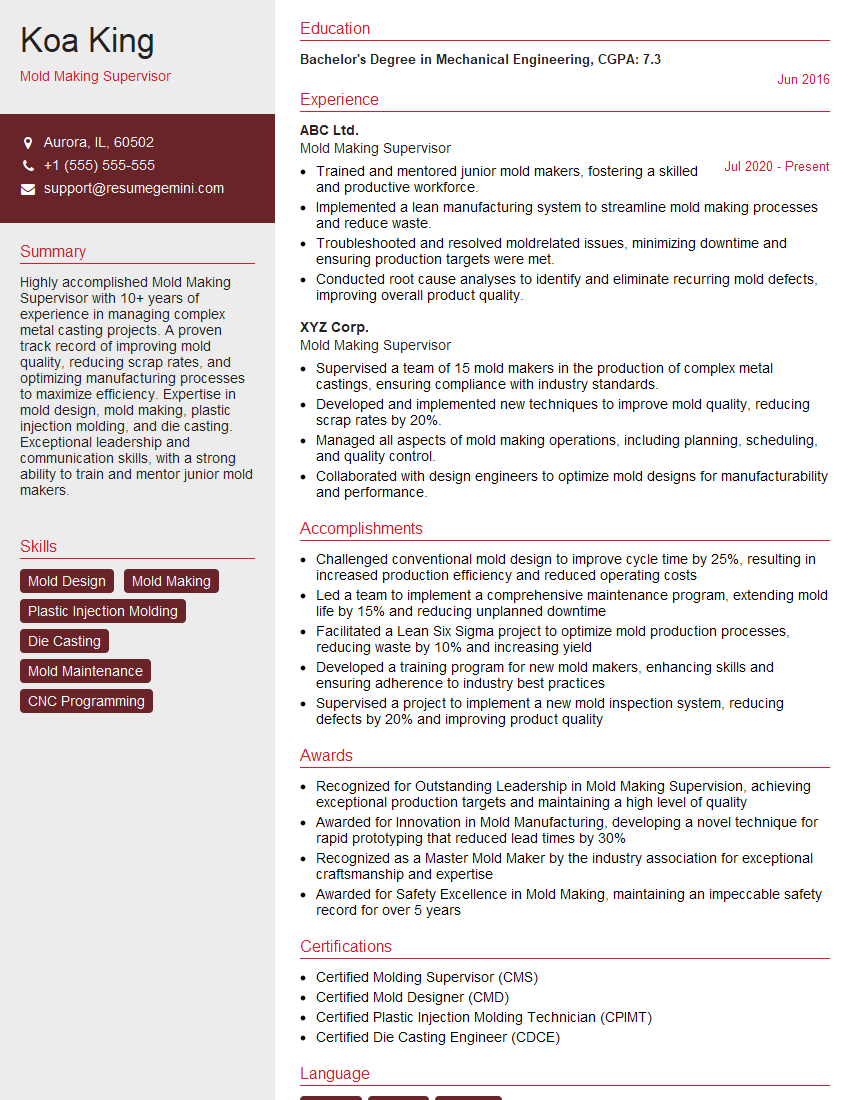

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Making Supervisor

1. Explain the steps involved in mold making.

Mold making involves several key steps:

- Design: Creating a 3D model of the desired object.

- Pattern Making: Carving or shaping a physical pattern based on the 3D model.

- Mold Creation: Using the pattern to create a mold that will produce the final object.

- Casting: Pouring molten material into the mold to form the object.

- Finishing: Removing the object from the mold and performing any necessary post-processing, such as polishing.

2. Describe the different types of materials used in mold making.

Metals

- Aluminum

- Iron

- Steel

Plastics

- Polyurethane

- Epoxy

- Silicone

Rubber

- Natural rubber

- Synthetic rubber

Wood

- Mahogany

- Oak

- Pine

3. How do you ensure the accuracy and quality of molds?

– Quality control measures are crucial for ensuring mold accuracy and quality:

- Inspection: Regularly checking molds for defects and wear.

- Calibration: Ensuring measurement equipment is up-to-date and accurate.

- Process Control: Monitoring environmental factors that can affect mold quality, such as temperature and humidity.

- Feedback: Gathering feedback from production teams and customers to identify areas for improvement.

4. What is the role of communication in mold making?

Communication is vital in mold making, involving various stakeholders:

- Design Team: Understanding their requirements and providing feedback on design feasibility.

- Production Team: Ensuring they have the necessary instructions and support to produce high-quality molds.

- Quality Control: Communicating quality issues and working together to resolve them.

- Customers: Keeping them informed about mold progress and addressing any concerns.

5. How do you handle production delays in mold making?

– Handling production delays requires a proactive and systematic approach:

- Identify Root Cause: Investigating the source of the delay to implement effective solutions.

- Reprioritize Tasks: Adjusting production schedules to prioritize urgent molds.

- Communicate with Stakeholders: Keeping everyone informed of delays and potential impact.

- Explore Alternative Options: Considering alternative materials or suppliers to minimize disruptions.

6. What are the common challenges faced in mold making?

- Defects: Imperfections or inconsistencies in molds that can affect part quality.

- Material Selection: Choosing the appropriate material for the specific application and production environment.

- Precision: Meeting demanding precision requirements for complex parts.

- Time Constraints: Balancing quality with timely delivery.

- Collaboration: Coordinating effectively with various departments and external stakeholders.

7. How do you ensure the sustainability of mold making operations?

Sustainability considerations are becoming increasingly important in mold making:

- Material Selection: Choosing environmentally friendly materials that minimize environmental impact.

- Waste Reduction: Implementing practices to reduce waste and promote recycling.

- Energy Efficiency: Optimizing production processes to minimize energy consumption.

- Supplier Management: Partnering with suppliers that share sustainability values.

8. What are the emerging trends in mold making?

- Additive Manufacturing: Utilizing 3D printing to create complex molds more efficiently.

- Automation: Implementing automated systems to streamline mold production.

- Advanced Materials: Developing new materials with improved properties and durability.

- Simulation: Using simulation software to optimize mold designs and reduce production time.

9. What is your approach to managing a team of mold makers?

My approach to managing a team of mold makers involves a combination of leadership and collaboration:

- Communication: Setting clear expectations, providing regular feedback, and fostering open communication channels.

- Motivation: Recognizing and rewarding achievements, creating a positive work environment, and providing opportunities for professional development.

- Delegation: Empowering team members to take ownership of their tasks and make informed decisions.

- Skill Development: Identifying skill gaps and providing training opportunities to enhance the team’s capabilities.

10. What are your career goals and how do you see this role contributing to your growth?

My career goals are to continue developing my expertise in mold making and to take on leadership responsibilities within the industry.

- This role would provide me with the opportunity to manage a team of skilled mold makers and contribute to the production of high-quality molds.

- It would also allow me to work on complex projects and learn from experienced professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Making Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Making Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Mold Making Supervisor is a crucial role in a manufacturing environment, responsible for overseeing the molding process, maintaining quality standards, and ensuring efficient operations. Key job responsibilities include:

1. Mold Production Management

- Supervise and direct the production of molds, ensuring adherence to design specifications and quality requirements.

- Monitor and control production schedules to meet deadlines and maintain productivity.

- Resolve production issues and implement corrective actions to minimize downtime.

2. Quality Control

intro paragraph

- Ensure that molds meet customer specifications and industry standards.

- Conduct regular inspections and audits to maintain quality levels.

- Implement and enforce quality control procedures throughout the manufacturing process.

3. Team Management

intro paragraph

- Lead and motivate a team of mold makers, ensuring their safety and productivity.

- Train and develop team members to improve their skills and knowledge.

- Foster a positive and collaborative work environment.

4. Process Improvement

intro paragraph

- Identify and implement process improvements to increase efficiency and reduce costs.

- Stay up-to-date with industry best practices and technology advancements.

- Collaborate with other departments to optimize the overall production process.

Interview Tips

To ace an interview for a Mold Making Supervisor position, candidates should prepare thoroughly. Here are some tips and hacks:

1. Research the Company and Industry

intro paragraph

- Visit the company website to learn about their products, services, and culture.

- Research the industry to understand current trends, challenges, and best practices.

2. Practice Common Interview Questions

intro paragraph

- Prepare for questions about your experience, qualifications, and leadership abilities.

- Practice answering behavioral questions using the STAR method (Situation, Task, Action, Result).

3. Highlight Quantifiable Achievements

intro paragraph

- Use specific examples to demonstrate your impact on previous roles.

- Quantify your accomplishments using metrics, such as increased productivity or reduced defects.

4. Be Enthusiastic and Professional

intro paragraph

- Show your passion for the industry and your eagerness to learn and grow.

- Dress professionally and arrive on time for the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Mold Making Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Mold Making Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.