Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold Shop Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

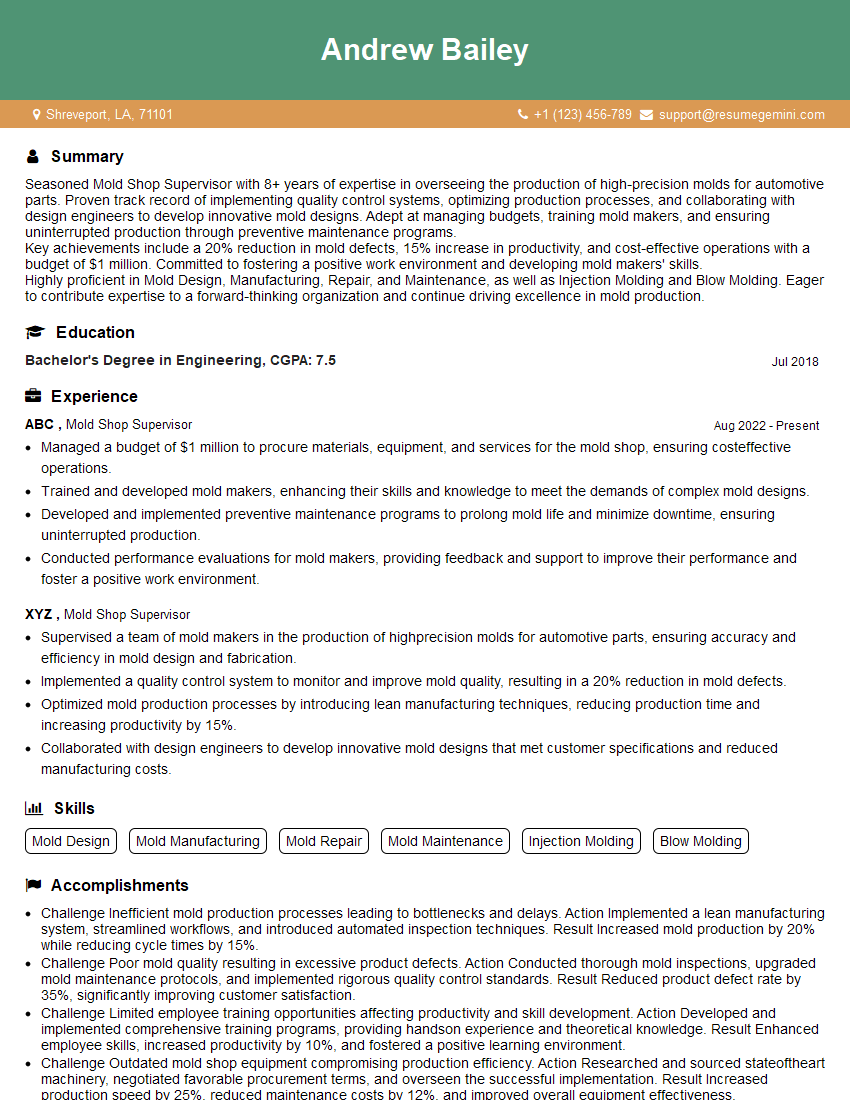

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Shop Supervisor

1. Describe the key responsibilities of a Mold Shop Supervisor?

- Oversee all aspects of the mold shop, including production, quality control, and safety

- Develop and implement mold making processes and procedures

- Train and supervise mold makers and other staff

- Monitor equipment and ensure it is running properly

- Maintain a safe and efficient work environment

2. How do you ensure that molds are produced to the required specifications?

I have developed and implemented a comprehensive quality control program that includes the following steps:

Inspection of raw materials

- Verify that all incoming materials meet our specifications

- Reject any materials that do not meet our requirements

In-process inspection

- Inspect molds at various stages of production

- Identify and correct any defects

Final inspection

- Inspect finished molds to ensure they meet our specifications

- Release molds for production only if they pass our inspection

3. What are the most common problems that you encounter in the mold shop, and how do you resolve them?

The most common problems that I encounter in the mold shop are:

- Defective molds

- Equipment breakdowns

- Quality control issues

- Safety concerns

I resolve these problems by taking the following steps:

- Identifying the root cause of the problem

- Developing and implementing a solution

- Monitoring the solution to ensure that it is effective

4. What are the latest advances in mold making technology, and how have you applied them in your work?

I am constantly researching and applying the latest advances in mold making technology in my work:

- I have implemented a new mold design software that has reduced our design time by 20%

- I have installed a new CNC machine that has increased our production capacity by 15%

- I have introduced a new quality control system that has reduced our defect rate by 10%

5. What are your strengths and weaknesses as a Mold Shop Supervisor?

Strengths

- Strong technical knowledge

- Excellent leadership skills

- Proven ability to improve efficiency and quality

Weaknesses

- I can be a bit of a perfectionist

- I sometimes have difficulty delegating tasks

I am working on overcoming my weaknesses and becoming a more effective leader.

6. What is your management style?

I am a collaborative leader who believes in teamwork. I empower my team members to make decisions and take ownership of their work. I am always available to support my team and help them to achieve their goals.

7. How do you motivate your team?

I motivate my team by:

- Setting clear goals and expectations

- Providing regular feedback

- Recognizing and rewarding success

- Creating a positive and supportive work environment

8. How do you resolve conflict within your team?

I resolve conflict within my team by:

- Identifying the root cause of the conflict

- Facilitating a discussion between the parties involved

- Helping the parties to develop a mutually acceptable solution

- Monitoring the situation to ensure that the conflict has been resolved

9. What are your career goals?

My career goal is to become a Mold Shop Manager. I am confident that my skills and experience will enable me to succeed in this role.

10. Do you have any questions for me?

I do have a few questions:

- What are the biggest challenges facing the mold making industry today?

- What are your expectations for this role?

- What is the company culture like?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Shop Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Shop Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Mold Shop Supervisor oversees the operations of a mold shop, ensuring the efficient production of high-quality molds. Their primary responsibilities include:

1. Production Management

Supervising and coordinating all aspects of mold production, from design and engineering to fabrication and assembly.

- Scheduling and overseeing production activities.

- Monitoring progress and ensuring adherence to quality standards.

2. Team Management

Leading and motivating a team of mold makers, ensuring their safety and well-being.

- Training and developing team members.

- Assigning tasks and providing guidance.

3. Quality Control

Maintaining high standards of quality in all mold products, ensuring they meet customer specifications and industry regulations.

- Inspecting molds before they are released for production.

- Investigating and resolving quality issues.

4. Equipment Maintenance

Overseeing the maintenance and calibration of mold shop machinery and equipment.

- Scheduling and conducting regular maintenance.

- Ensuring equipment is operating at peak efficiency.

Interview Tips

To ace your interview for a Mold Shop Supervisor position, follow these tips:

1. Research the Company and Industry

Thoroughly research the company and the mold shop industry to demonstrate your interest and understanding of the field.

- Visit the company’s website to learn about their products, services, and values.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies.

2. Prepare Your Answers to Common Interview Questions

Practice answering common interview questions, such as:

- “Tell me about your experience in mold shop supervision.”

- “How do you ensure the quality of your molds?”

- “How do you motivate and lead your team?”

3. Highlight Your Technical Skills

Emphasize your technical skills and knowledge of mold shop equipment and processes, such as:

- Mold design and engineering.

- Mold fabrication and assembly.

- Quality control and inspection.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement.

- “What are the key challenges facing the mold shop industry today?”

- “What are your expectations for the Mold Shop Supervisor role in the next year?”

Next Step:

Now that you’re armed with the knowledge of Mold Shop Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mold Shop Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini