Are you gearing up for a career in Plating and Point Assembly Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Plating and Point Assembly Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

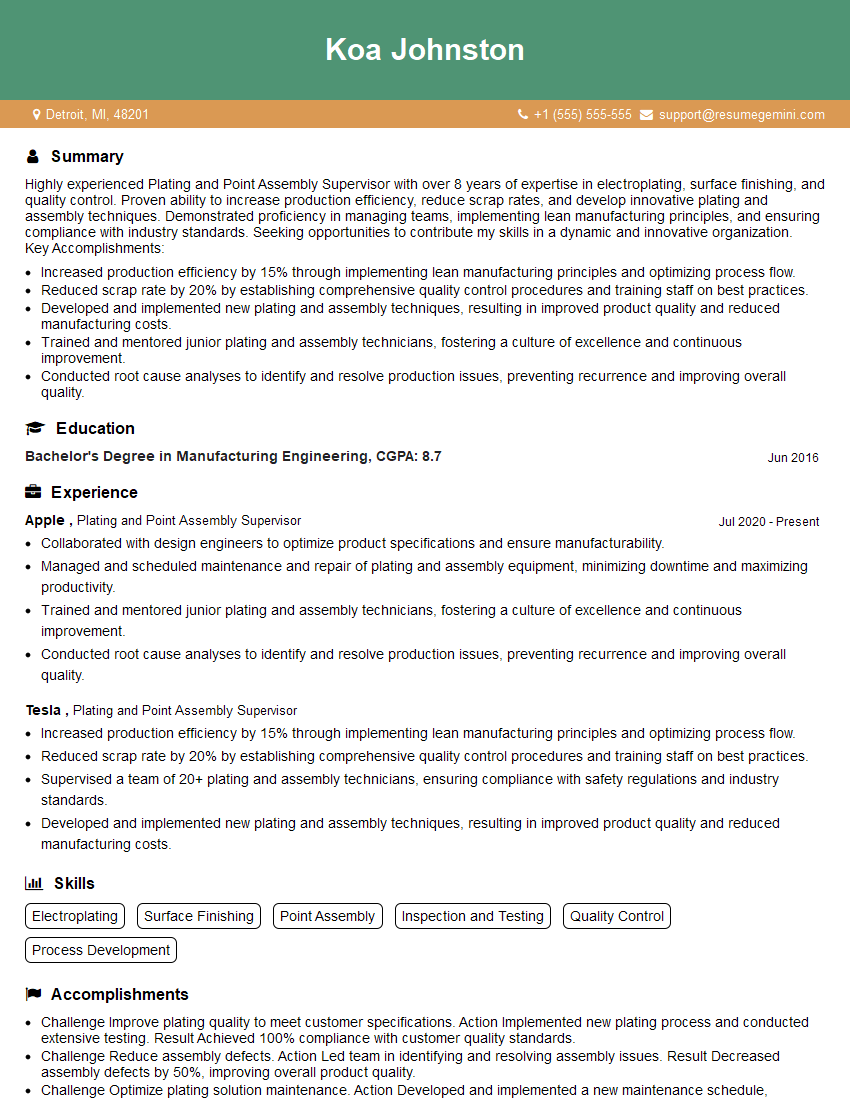

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plating and Point Assembly Supervisor

1. What are the key steps involved in the plating process?

The key steps involved in the plating process are:

- Cleaning and preparing the surface

- Applying a conductive coating

- Electroplating the desired metal

- Post-treatment

2. What are the different types of plating processes and their applications?

Electroplating

- Used to deposit a layer of metal onto a surface

- Applications: automotive parts, jewelry, electronics

Electroless plating

- Used to deposit a metal layer without the use of electricity

- Applications: Printed circuit boards, semiconductors

Vapor deposition

- Used to deposit a metal layer in a vacuum environment

- Applications: Optical coatings, cutting tools

3. What are the important factors to consider when selecting a plating process?

Important factors to consider when selecting a plating process include:

- The material to be plated

- The desired thickness and uniformity of the plating

- The cost and availability of the plating process

- The environmental impact of the plating process

4. What are the quality control measures that need to be implemented in a plating operation?

Quality control measures for a plating operation include:

- Testing the thickness and uniformity of the plating

- Inspecting the plated surface for defects

- Monitoring the plating solution

- Calibrating the plating equipment

5. What are the common problems that can occur in a plating operation and how can they be resolved?

Common problems in plating operations include:

- Poor adhesion: Can be caused by improper surface preparation or contamination. Solution: Clean and prepare the surface properly.

- Pitting: Can be caused by impurities in the plating solution or improper operating conditions. Solution: Filter the plating solution and adjust the operating conditions.

- Blistering: Can be caused by hydrogen gas entrapment in the plating. Solution: Use a brightener or leveler in the plating solution.

6. What are the safety precautions that need to be taken when working with plating chemicals?

Safety precautions for working with plating chemicals include:

- Wearing protective clothing and equipment

- Working in a well-ventilated area

- Properly disposing of plating chemicals

- Being aware of the hazardous properties of plating chemicals

7. What are the different types of point assembly operations?

Types of point assembly operations include:

- Manual assembly: Performed by hand

- Automated assembly: Performed by machines

- Hybrid assembly: Combination of manual and automated assembly

8. What are the factors to consider when designing a point assembly process?

Factors to consider when designing a point assembly process include:

- The product design

- The materials used

- The assembly sequence

- The assembly equipment

- The quality control requirements

9. What are the common problems that can occur in a point assembly operation and how can they be resolved?

Common problems in point assembly operations include:

- Misalignment: Can be caused by improper fixturing or assembly equipment. Solution: Calibrate the assembly equipment and use fixtures to ensure proper alignment.

- Defective components: Can be caused by poor quality control in the component manufacturing process. Solution: Implement a robust quality control system to prevent defective components from entering the assembly process.

- Assembly errors: Can be caused by human error or improper assembly training. Solution: Provide proper training to assembly operators and implement visual aids to prevent errors.

10. What are the key performance indicators (KPIs) for a point assembly operation?

KPIs for a point assembly operation include:

- Throughput: The number of assemblies produced per hour

- Yield: The percentage of assemblies that pass quality inspection

- First-pass yield: The percentage of assemblies that pass quality inspection on the first pass

- Defect rate: The percentage of assemblies that fail quality inspection

- Cycle time: The time it takes to assemble a single product

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plating and Point Assembly Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plating and Point Assembly Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Plating and Point Assembly Supervisor is a vital role in ensuring the efficient and effective operation of a plating and assembly department. Key responsibilities include:

1. Production and Quality Management

Supervising and managing the production and assembly processes, ensuring adherence to quality standards

- Establishing and implementing production schedules and quality control measures

- Monitoring production lines to identify potential issues and implement corrective actions

2. Team Leadership and Development

Leading, motivating, and training a team of plating and assembly technicians

- Providing clear instructions and guidance, fostering a positive and productive work environment

- Identifying and developing team members’ skills and capabilities

3. Process Optimization and Troubleshooting

Optimizing plating and assembly processes to enhance efficiency and quality

- Analyzing production data to identify areas for improvement and implementing solutions

- Troubleshooting and resolving technical issues that arise during the plating and assembly process

4. Inventory and Equipment Management

Managing inventory levels of raw materials, parts, and equipment

- Ordering materials and supplies to ensure uninterrupted production

- Maintaining and calibrating equipment to ensure accuracy and safety

Interview Tips

Preparing thoroughly for an interview is essential to showcase your skills and experience and increase your chances of success.

1. Research the Company and Position

Gather information about the company, its products, and the specific role you’re applying for. This will help you understand the company’s culture and demonstrate your interest in the position.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about the latest trends.

2. Practice Your Answers

Prepare thoughtful and articulate answers to common interview questions. Practice delivering your answers clearly and concisely.

- Example Outline:

- Tell us about your experience supervising a plating and assembly team.

- Situation: Describe a specific team project or initiative you led, highlighting your leadership style and results achieved.

- Task: Explain the challenges or obstacles you faced and how you overcame them.

- Action: Showcase the specific actions you took to improve team performance or optimize the production process.

- Result: Quantify the positive outcomes of your efforts, such as increased productivity or improved quality.

3. Dress Professionally and Be Punctual

First impressions matter. Dress appropriately for the interview and arrive on time to demonstrate your respect for the interviewer and the company.

- Consider wearing business attire, such as a suit or a dress shirt and slacks.

- Be punctual, as arriving late can reflect negatively on your professionalism.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the role.

- Inquire about the company’s growth plans or industry outlook.

- Ask about the training and development opportunities available.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plating and Point Assembly Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!