Are you gearing up for a career in Pot Room Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pot Room Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

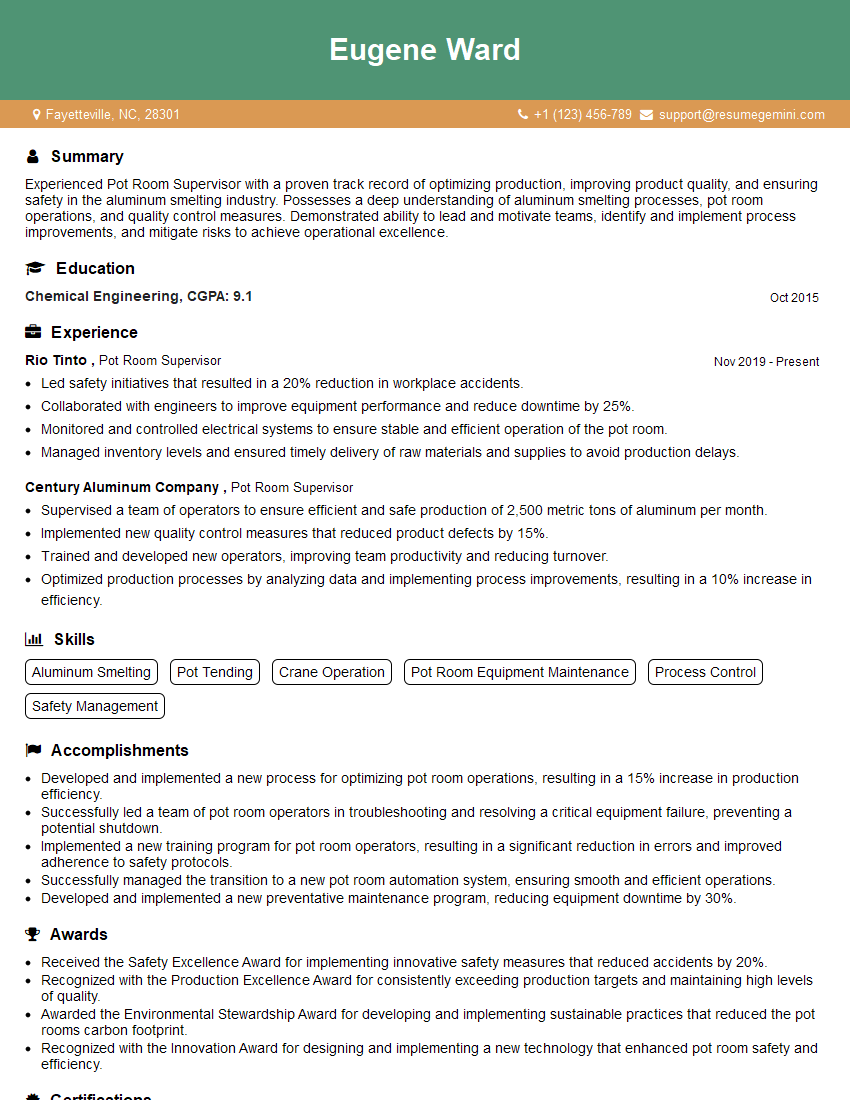

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pot Room Supervisor

1. What are the key aspects of pot room operations that you would focus on to optimize production efficiency?

– Implement a comprehensive maintenance program to ensure equipment reliability. – Optimize scheduling and workforce allocation to minimize downtime and maximize production capacity. – Monitor and control process parameters to maintain optimal operating conditions and minimize losses. – Train and empower operators to identify and resolve issues promptly, minimizing production disruptions.

2. How would you address a sudden increase in potroom temperature that could potentially impact production?

Immediate Actions:

- Identify the root cause of the temperature increase (e.g., equipment malfunction, ventilation issues).

- Implement immediate measures to cool down the potroom, such as increasing ventilation and adjusting operating parameters.

Long-Term Measures:

- Conduct a thorough investigation to determine the underlying issue and develop corrective actions.

- Review maintenance schedules and identify areas for improvement to prevent similar incidents in the future.

3. What are the critical safety measures that you would enforce in a pot room environment?

- Enforce the use of personal protective equipment (PPE) such as fire-resistant clothing, gloves, and safety glasses.

- Establish clear operating procedures and ensure operators are trained on proper handling of molten metal and other hazardous materials.

- Conduct regular safety audits and inspections to identify potential hazards and implement corrective actions.

- Provide emergency response training and maintain a well-equipped first aid station.

4. How would you monitor and control the quality of the produced aluminum?

– Establish and maintain a quality assurance program that includes regular sampling and testing of the molten metal. – Monitor key process parameters such as temperature, voltage, and current to ensure optimal conditions for metal quality. – Implement statistical process control techniques to identify trends and minimize variability in production. – Train operators on quality control procedures and empower them to make necessary adjustments based on test results.

5. What are the key indicators of a well-performing pot room?

- High production efficiency and minimal downtime.

- Consistent production of high-quality aluminum with low impurity levels.

- Effective maintenance practices that minimize equipment breakdowns and prolong asset life.

- Strong safety record and compliance with all applicable regulations.

- Low operating costs and high profitability.

6. How would you motivate and develop your team in a pot room environment?

- Create a positive and inclusive work culture that values teamwork and collaboration.

- Provide clear performance expectations and regular feedback to help employees understand their roles and areas for improvement.

- Offer opportunities for training and development to enhance skills and knowledge.

- Recognize and reward employee achievements to foster a sense of accomplishment.

- Encourage open communication and employee involvement in decision-making processes.

7. What are the potential challenges in managing a pot room operation, and how would you overcome them?

– Equipment breakdowns and maintenance issues: Implement a rigorous maintenance program, train operators on basic troubleshooting, and maintain a stock of critical spare parts. – Fluctuations in aluminum prices: Develop a flexible production plan that can adjust to market conditions and minimize financial impact. – Workforce shortages: Invest in employee training and development, offer competitive compensation and benefits, and foster a positive work environment to attract and retain skilled workers. – Environmental regulations: Stay up-to-date on environmental laws and regulations, invest in pollution control technologies, and promote sustainable practices.

8. How do you stay abreast of the latest advancements in pot room technology?

- Attend industry conferences and exhibitions.

- Read technical journals and research papers.

- Collaborate with equipment manufacturers and technology providers.

- Implement a continuous improvement program to identify and evaluate potential improvements.

9. What are the key performance indicators (KPIs) that you would track to measure the effectiveness of a pot room operation?

- Production efficiency (tons of aluminum produced per day).

- Metal quality (purity levels and impurity content).

- Equipment uptime and maintenance costs.

- Safety record (lost time injuries).

- Cost of production per ton of aluminum.

10. How would you ensure a smooth handover of operations in the event of an emergency or absence?

- Establish clear lines of succession and responsibilities for key roles.

- Document all critical procedures and operating guidelines.

- Conduct regular training and cross-training to ensure all employees are familiar with different aspects of the operation.

- Maintain open communication and information sharing among team members.

- Develop a comprehensive emergency response plan and conduct regular drills to ensure preparedness.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pot Room Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pot Room Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Pot Room Supervisor is responsible for overseeing the safe and efficient operation of the pot room, ensuring that production targets are met and quality standards are maintained.

1. Production Management

Directing and coordinating pot room operations to ensure smooth production workflow.

- Scheduling and assigning tasks to operators.

- Monitoring production output and identifying areas for improvement.

2. Quality Control

Establishing and maintaining quality standards for pot room products.

- Inspecting raw materials and finished products.

- Implementing quality control procedures and ensuring compliance.

3. Safety Management

Prioritizing the safety of employees and maintaining a safe working environment.

- Enforcing safety regulations and conducting safety training.

- Identifying and eliminating potential hazards.

4. Equipment Maintenance

Ensuring the proper functioning of pot room equipment.

- Scheduling and overseeing equipment maintenance.

- Coordinating with maintenance personnel for repairs and replacements.

Interview Tips

To prepare for your Pot Room Supervisor interview, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, operations, and culture. Study the job description thoroughly to understand the specific responsibilities and qualifications required.

- Visit the company website and social media pages.

- Read industry publications and articles.

2. Highlight Your Experience and Skills

Emphasize your relevant experience in pot room operations, quality control, safety management, and equipment maintenance. Quantify your accomplishments with specific examples and data whenever possible.

- Describe how you improved production efficiency or reduced waste.

- Share examples of successful safety initiatives you implemented.

3. Demonstrate Leadership and Communication Skills

Supervisors are responsible for leading and motivating a team. Showcase your leadership abilities, including how you effectively manage and inspire others. Highlight your communication skills and how you build strong relationships with colleagues and superiors.

- Mention instances where you successfully resolved conflicts or provided guidance to team members.

- Describe how you effectively communicated production targets, quality standards, and safety procedures.

4. Be Prepared for Technical Questions

Anticipate technical questions related to pot room operations, quality control methods, and safety regulations. Review the fundamentals of these topics and prepare examples of how you have applied them in previous roles.

- Explain the principles of electrolysis and how it is used in pot room operations.

- Discuss different quality control techniques used in pot room environments.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pot Room Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pot Room Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.