Feeling lost in a sea of interview questions? Landed that dream interview for Porcelain Enameling Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Porcelain Enameling Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

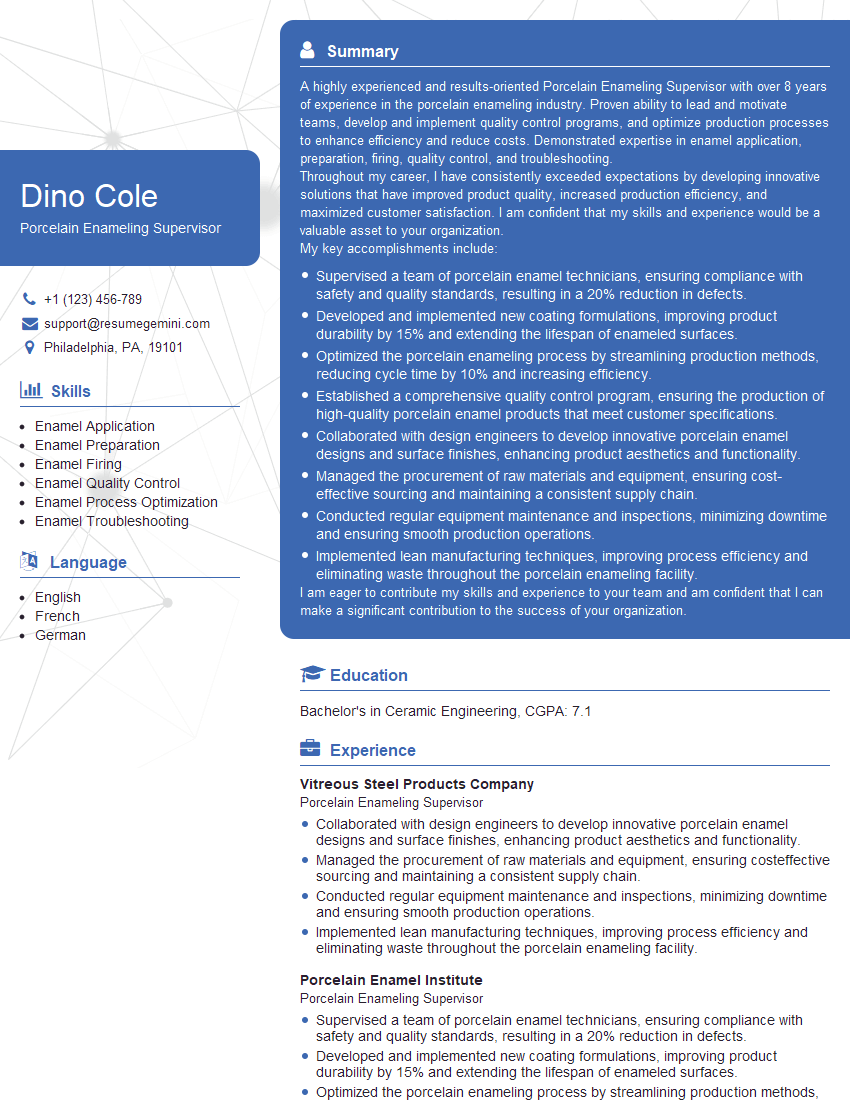

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Porcelain Enameling Supervisor

1. What are the critical aspects of porcelain enamel mixing and application?

Critical aspects of porcelain enamel mixing and application include:

- Raw material selection and preparation: Ensuring the purity and particle size distribution of raw materials to achieve desired enamel properties.

- Slurry preparation: Achieving the optimal consistency, viscosity, and suspension properties for proper enamel application.

- Application techniques: Controlling dipping, spraying, or electrostatic deposition processes to ensure uniform coating thickness and adherence.

- Drying and firing: Optimizing temperature profiles and firing atmosphere to attain the desired enamel microstructure and properties.

- Quality control: Implementing testing procedures to evaluate enamel properties and ensure adherence to specifications.

2. Describe the different types of porcelain enamel defects and their causes.

of the answer: Enamel Defects Related to Substrate

- Blisters and bubbles: Caused by gas entrapment during firing due to improper cleaning, surface contamination, or trapped moisture.

- Warpage: Resulting from uneven heating, thermal expansion mismatch, or insufficient support during firing.

Subheading of the answer: Enamel Defects Related to Application

- Pitting and pinholes: Caused by trapped air or gas during application, improper firing, or insufficient enamel coverage.

- Crazing: Fine cracks in the enamel due to thermal expansion mismatch, uneven cooling, or substrate contamination.

- Chipping and spalling: Resulting from poor adhesion, mechanical stress, or improper firing schedules.

3. What methods are used to test the durability and performance of porcelain enamels?

Methods to test the durability and performance of porcelain enamels include:

- Adhesion testing: Evaluating the bond strength between the enamel and the substrate using techniques like pull-off testing or scratch testing.

- Thermal cycling testing: Assessing enamel resistance to repeated heating and cooling cycles, mimicking real-world conditions.

- Chemical resistance testing: Determining enamel stability in various corrosive environments, such as acidic or alkaline solutions.

- Gloss and color measurement: Evaluating the optical properties of the enamel surface using spectrophotometers.

- Abrasion resistance testing: Measuring the durability of the enamel under abrasive forces using taber abraser or sandblasting.

4. What factors influence the choice of frit for a particular porcelain enamel application?

Factors influencing the choice of frit for a porcelain enamel application include:

- Substrate type and composition: Ensuring compatibility between the enamel and the substrate material.

- Intended use and service conditions: Considering factors such as temperature, chemical exposure, and wear resistance.

- Enamel properties required: Selecting frits that provide the desired opacity, gloss, texture, and color.

- Manufacturing process: Optimizing frit selection for specific application techniques such as dipping or spraying.

- Cost and availability: Considering factors related to frit production and market availability.

5. Describe the role of quality control in porcelain enameling operations.

Quality control in porcelain enameling operations plays a critical role in ensuring product consistency and meeting specifications:

- Raw material inspection: Verifying the quality and consistency of incoming raw materials.

- Process monitoring: Monitoring enamel mixing, application, and firing parameters to maintain optimal conditions.

- Enamel testing: Conducting regular tests on enamel properties such as adhesion, durability, and appearance.

- Defects analysis: Investigating enamel defects, identifying their causes, and implementing corrective actions.

- Documentation and record-keeping: Maintaining detailed records of production parameters, test results, and any deviations from specifications.

6. Describe your experience with troubleshooting common porcelain enamel defects.

In my previous role as a Porcelain Enameling Supervisor, I have encountered and resolved various common enamel defects:

- Blistering: Identified trapped air or moisture in the enamel slurry and implemented measures to improve mixing and application techniques.

- Crazing: Detected thermal expansion mismatch between the enamel and substrate and adjusted firing schedules to minimize stress.

- Chipping: Determined insufficient adhesion due to substrate contamination and implemented improved cleaning processes.

- Discoloration: Traced the issue to impurities in the raw materials and worked with suppliers to ensure material quality.

7. How do you ensure the safety of your team while working with porcelain enamel materials?

Ensuring team safety is a top priority in my approach:

- Personal Protective Equipment (PPE): Enforcing the use of appropriate PPE, including gloves, respirators, and protective clothing.

- Hazard Communication: Providing comprehensive training on potential hazards and safe handling procedures.

- Ventilation and Air Quality: Ensuring proper ventilation and monitoring air quality to minimize exposure to harmful fumes.

- Emergency Preparedness: Establishing emergency protocols and providing training on spill containment and response.

- Regular Safety Inspections: Regularly inspecting work areas and equipment to identify and address potential safety hazards.

8. What are the latest advancements in porcelain enameling technology that you are aware of?

I stay updated with the latest advancements in porcelain enameling technology:

- Digital Printing: Exploring the use of digital printing techniques to create intricate designs and patterns on porcelain enamel surfaces.

- Nanocomposite Enamels: Researching nanocomposite enamels that offer enhanced properties such as durability and antimicrobial resistance.

- Sustainable Enameling: Investigating environmentally friendly enameling processes that reduce waste and emissions.

- Automation and Process Control: Implementing automation and advanced process control techniques to improve efficiency and consistency.

- Smart Coatings: Developing smart coatings with self-cleaning, anti-fouling, or energy-efficient properties.

9. How do you manage production schedules and prioritize tasks to meet customer deadlines?

I effectively manage production schedules and prioritize tasks to meet customer deadlines through the following approaches:

- Production Planning: Collaborating with the production team to develop detailed production schedules based on customer orders and lead times.

- Task Prioritization: Using prioritization techniques such as the Eisenhower Matrix to identify and focus on the most critical tasks.

- Resource Allocation: Optimizing resource allocation to ensure timely completion of tasks, considering factors such as availability and skills.

- Communication and Coordination: Maintaining open communication with customers and production staff to manage expectations and address any changes in schedule.

- Continuous Improvement: Regularly reviewing production processes to identify areas for improvement and enhance efficiency.

10. Can you provide an example of a successful project that you led in porcelain enameling?

In my previous role, I led a project to implement a new porcelain enamel production line, which significantly improved efficiency and reduced production costs:

- Equipment Selection: Researched and selected state-of-the-art equipment to optimize production speed and quality.

- Process Optimization: Developed and implemented new enameling processes to minimize waste and improve enamel properties.

- Training and Development: Provided comprehensive training to the production team on the new equipment and processes.

- Quality Control: Established a rigorous quality control system to ensure adherence to specifications and customer requirements.

- Collaboration and Communication: Fostered collaboration and open communication among the team, leading to a successful project implementation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Porcelain Enameling Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Porcelain Enameling Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Porcelain Enameling Supervisor plays a crucial role in overseeing the porcelain enameling process, ensuring the production of high-quality enameled products. Their key responsibilities include:

1. Production Management

Supervising and coordinating all aspects of porcelain enameling operations, including scheduling, staffing, and resource allocation.

2. Quality Control

Establishing and maintaining quality standards for porcelain enameling processes, inspecting finished products, and implementing corrective actions to address any deviations.

3. Process Optimization

Identifying and implementing process improvements to enhance efficiency, reduce waste, and improve product quality.

4. Troubleshooting and Problem-Solving

Diagnosing and resolving production issues, equipment malfunctions, and quality defects, ensuring timely and effective problem resolution.

5. Training and Development

Providing training to team members on porcelain enameling techniques and best practices, fostering a skilled and knowledgeable workforce.

6. Health and Safety Management

Ensuring compliance with health and safety regulations, maintaining a safe work environment, and promoting employee well-being.

Interview Tips

To ace an interview for a Porcelain Enameling Supervisor position, candidates should prepare thoroughly and demonstrate their knowledge and skills.

1. Research the Company and Industry

ознакомьтесь с компанией, ее рынком и отраслевыми тенденциями, чтобы продемонстрировать свою осведомленность и интерес к позиции.

2. Highlight Relevant Experience

подчеркните свой релевантный опыт в области фарфоровой эмалирования, контроля качества и управления производством, приводя конкретные примеры ваших достижений.

3. Prepare for Technical Questions

изучите технические аспекты фарфоровой эмали, такие как типы эмалей, процессы нанесения и методы контроля качества, чтобы уверенно отвечать на вопросы интервьюера.

4. Emphasize Problem-Solving Skills

опишите ситуации, в которых вы успешно диагностировали и решили проблемы, связанные с эмалированием, демонстрируя свои аналитические и критически мыслящие способности.

5. Show Leadership Qualities

продемонстрируйте свои лидерские навыки, обсудив примеры, когда вы мотивировали, наставляли и обучали команду для достижения целей.

6. Prepare Questions

подготовьте вдумчивые вопросы для интервьюера, которые покажут вашу заинтересованность в позиции и компании.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Porcelain Enameling Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!