Feeling lost in a sea of interview questions? Landed that dream interview for Production Department Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Production Department Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

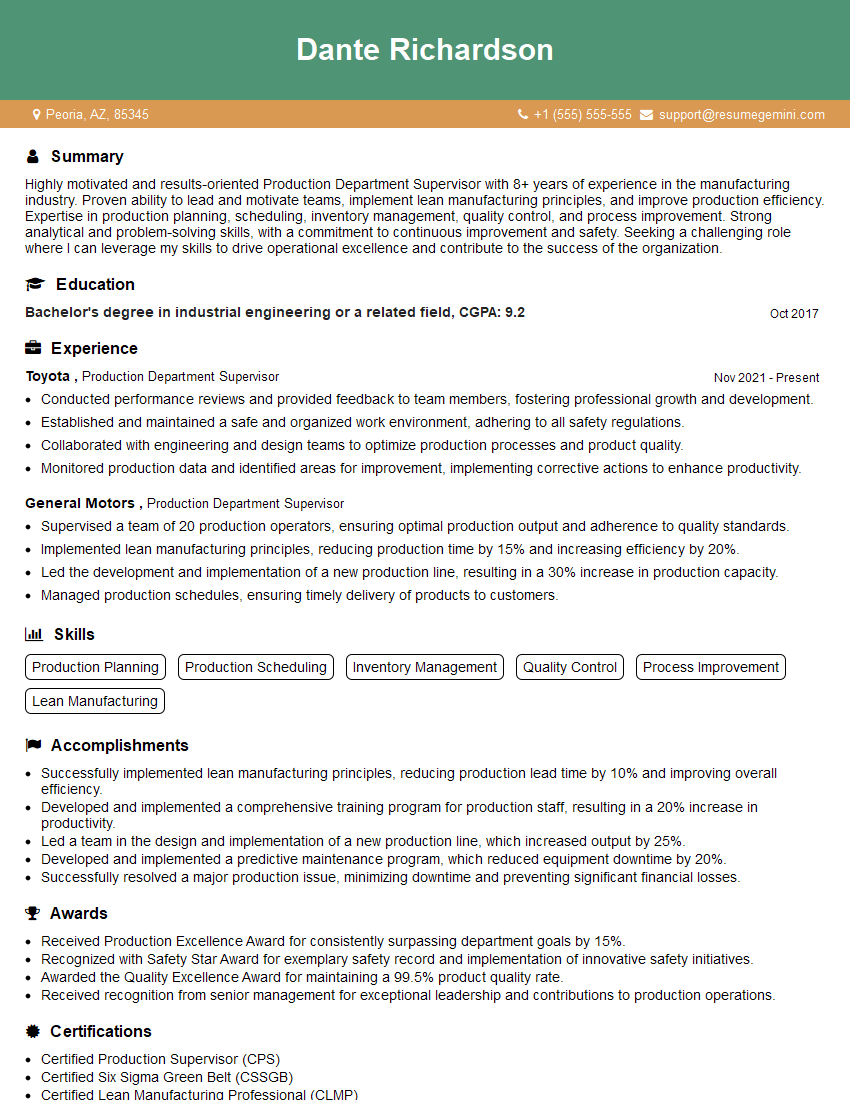

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Department Supervisor

1. Describe the key performance indicators (KPIs) you use to measure the effectiveness of a production department?

- Production output: Quantity of products produced compared to targets.

- Quality rate: Percentage of products meeting quality standards.

- Efficiency rate: Ratio of actual production time to standard time.

- Lead time: Time from order placement to product delivery.

- Cost per unit: Total production costs divided by the number of units produced.

2. How do you ensure that production schedules are met while maintaining quality standards?

Coordination and Planning

- Collaborate with other departments to align production schedules with sales forecasts.

- Establish realistic schedules based on capacity, lead times, and resources.

Monitoring and Adjustment

- Regularly track progress against schedules and identify potential bottlenecks.

- Implement corrective actions, such as adjusting schedules or allocating additional resources, to prevent delays.

Quality Control

- Establish clear quality standards and implement inspection procedures.

- Train staff on quality control techniques and provide feedback to ensure adherence.

3. What are the most common challenges you face in managing a production department and how do you overcome them?

- Resource constraints: Effectively allocate resources, prioritize tasks, and explore outsourcing options.

- Equipment breakdowns: Establish preventive maintenance schedules, have backup equipment available, and cross-train staff for multiple roles.

- Quality issues: Implement rigorous quality control measures, provide training, and empower employees to address quality concerns.

- Unexpected fluctuations in demand: Adjust production schedules, collaborate with sales and marketing to forecast demand, and build relationships with suppliers to ensure material availability.

4. How do you motivate and engage your production team to achieve high performance?

- Clear communication: Establish clear expectations and provide regular feedback.

- Recognition and rewards: Acknowledge and reward achievements to foster motivation.

- Training and development: Provide opportunities for staff to enhance their skills and grow professionally.

- Empowerment: Delegate decision-making to team members and encourage problem-solving.

- Team building activities: Promote collaboration and create a positive work environment.

5. How do you manage inventory levels to optimize production and minimize costs?

- Forecasting and demand planning: Collaborate with sales and marketing to accurately forecast customer demand.

- Just-in-time (JIT) inventory: Reduce storage costs by ordering materials and components as needed.

- Economic Order Quantity (EOQ): Determine the optimal order quantity to minimize total inventory costs.

- ABC analysis: Categorize inventory items based on usage and value to prioritize management.

6. How do you ensure continuous improvement in production processes?

- Performance monitoring: Track key performance indicators and identify areas for improvement.

- Employee feedback: Gather input from team members and implement suggestions to enhance efficiency.

- Technology adoption: Explore and implement new technologies to automate tasks and improve accuracy.

- Lean manufacturing principles: Eliminate waste, optimize processes, and reduce costs.

7. How do you handle the introduction of new products or changes to production lines?

- Planning and coordination: Collaborate with engineering, design, and sales teams to plan the introduction.

- Equipment and tooling evaluation: Assess the need for new or modified equipment and tools.

- Process development: Establish production processes that meet quality standards and optimize efficiency.

- Training and documentation: Provide thorough training to staff and update documentation to reflect changes.

8. Describe your experience in implementing quality management systems in a production environment.

- ISO 9001 certification: Led the implementation and maintenance of an ISO 9001 quality management system.

- Six Sigma methodology: Utilized Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) to identify and eliminate process defects.

- Process mapping and documentation: Created and maintained detailed process maps and documentation to ensure compliance.

- Continuous improvement: Initiated and implemented quality improvement initiatives to enhance processes and reduce waste.

9. How do you leverage data to drive decision-making and improve production efficiency?

- Data collection and analysis: Utilize production data, such as machine performance and quality metrics, to identify trends and patterns.

- Predictive analytics: Employ statistical models to predict future outcomes and optimize production schedules.

- Visual dashboards: Create interactive dashboards to visualize data and provide insights for decision-makers.

- Data-driven decision-making: Use data to make informed decisions that improve production efficiency and minimize risks.

10. What are the emerging technologies and trends that you believe will shape the future of production management?

- Industry 4.0 and automation: Increased adoption of automation, robotics, and AI to enhance efficiency and reduce labor costs.

- Cloud computing and IoT: Utilization of cloud-based platforms and IoT devices to monitor and control production processes remotely.

- Additive manufacturing (3D printing): Growing use of 3D printing for prototyping, customization, and small-scale production.

- Sustainability and circular economy: Focus on reducing environmental impact and promoting sustainable practices in production.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Department Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Department Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Production Department Supervisor is responsible for overseeing all aspects of production, ensuring smooth operations and meeting production goals. Key responsibilities include:

1. Production Planning and Execution

Plan and schedule production activities, including material procurement, resource allocation, and quality control.

- Develop and execute production plans to meet customer orders and delivery deadlines.

- Manage and coordinate production resources, such as equipment, materials, and labor.

2. Quality Control and Assurance

Establish and maintain quality standards throughout the production process.

- Inspect and monitor production processes to ensure adherence to specifications and regulations.

- Identify and resolve quality issues promptly to prevent defects and ensure product integrity.

3. Team Management and Development

Lead and motivate a team of production workers.

- Train, supervise, and evaluate production team members.

- Foster a positive and productive work environment, promoting teamwork and collaboration.

4. Cost Optimization and Efficiency

Analyze production processes and identify areas for improvement.

- Implement cost-effective measures to reduce waste and increase efficiency.

- Maximize resource utilization and optimize production schedules to minimize production costs.

Interview Tips

To ace your interview for a Production Department Supervisor position, consider the following tips:

1. Research the Company and Industry

Thoroughly research the company and industry to demonstrate your understanding of the market and operations.

- Visit the company’s website and social media pages to learn about their culture, values, and products/services.

- Read industry news and reports to stay informed about trends and best practices.

2. Practice Answering Common Interview Questions

Prepare for common interview questions by brainstorming and practicing your responses. Anticipate questions about your production management experience, leadership skills, and problem-solving abilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

- Consider potential situational questions and demonstrate your critical thinking and decision-making skills.

3. Highlight Your Leadership Abilities

Emphasize your experience in leading and motivating production teams. Showcase your ability to set clear expectations, delegate effectively, and resolve conflicts.

- Provide examples of how you have inspired and empowered your team to achieve production goals.

- Discuss your strategies for building a strong and productive work environment.

4. Demonstrate Your Problem-Solving Skills

Interviewers are keen on assessing your problem-solving abilities. Share examples of how you have identified and resolved production issues, implemented improvements, and optimized processes.

- Use the STAR method to describe a specific production challenge you faced and how you overcame it.

- Explain your analytical approach and the steps you took to resolve the issue.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Show passion for your field and demonstrate your commitment to contributing to the company’s success.

- Express your eagerness to join the team and contribute your expertise.

- Be respectful and professional in your interactions with the interviewers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Department Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!