Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Production Welding Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

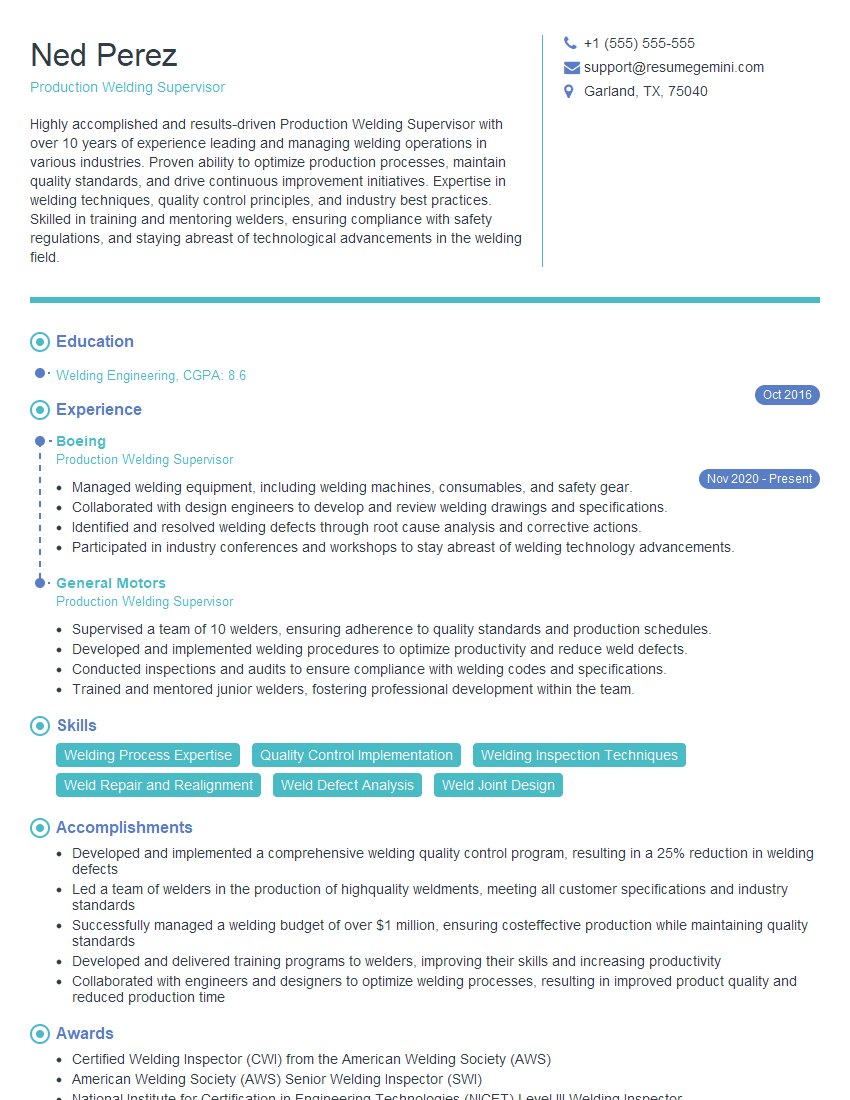

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Welding Supervisor

1. What are the different types of welding processes used in your previous role and which one do you consider to be the most efficient?

- Gas Metal Arc Welding (GMAW) or MIG welding: This process uses a continuously fed wire electrode and a shielding gas to create an arc between the electrode and the workpiece.

- Gas Tungsten Arc Welding (GTAW) or TIG welding: This process uses a non-consumable tungsten electrode and a shielding gas to create an arc between the electrode and the workpiece.

- Shielded Metal Arc Welding (SMAW) or stick welding: This process uses a consumable electrode covered with a flux to create an arc between the electrode and the workpiece.

- Flux-Cored Arc Welding (FCAW): This process uses a continuously fed tubular wire electrode that contains flux to create an arc between the electrode and the workpiece.

2. How do you ensure that weld quality meets the required standards and specifications?

subheading of the answer

- Visual inspection: This involves examining the weld for any visible defects, such as cracks, porosity, or undercut.

- Dye penetrant testing: This involves applying a dye to the weld and then removing it to reveal any surface defects.

- Magnetic particle testing: This involves applying magnetic particles to the weld and then magnetizing it to reveal any subsurface defects.

- Ultrasonic testing: This involves using sound waves to detect any internal defects in the weld.

- Radiographic testing: This involves using X-rays or gamma rays to create an image of the weld and reveal any internal defects.

subheading of the answer

- Following the welding procedures and specifications.

- Using qualified welders.

- Inspecting welds regularly.

- Taking corrective action when necessary.

3. In terms of welding equipment, what are the key factors that contribute to achieving optimal weld quality?

- The type of welding machine.

- The welding power source.

- The welding torch or gun.

- The welding consumables.

- The welding environment.

4. How do you handle situations where there are discrepancies between welding specifications and actual production conditions?

- Communicate with the engineering or design team to clarify the specifications.

- Conduct tests or trials to determine the feasibility of meeting the specifications under the actual production conditions.

- Propose alternative welding methods or parameters that can meet the specifications while considering the production constraints.

- Document the deviations from the specifications and obtain approval from the relevant authorities.

5. What techniques do you use to minimize welding defects and ensure product quality?

- Proper joint preparation.

- Using the correct welding parameters.

- Weld sequencing.

- Post-weld heat treatment.

- Non-destructive testing.

6. How do you stay updated with the latest welding technologies and advancements?

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Participating in online forums and discussion groups.

- Seeking training and certification from recognized organizations.

7. What are the key factors to consider when selecting welding consumables?

- The type of metal being welded.

- The welding process being used.

- The desired weld properties.

- The cost of the consumables.

- The availability of the consumables.

8. How do you manage a team of welders and ensure their productivity and quality of work?

- Providing clear instructions and expectations.

- Monitoring their progress and providing feedback.

- Recognizing and rewarding their achievements.

- Creating a positive and supportive work environment.

- Empowering them to make decisions and take ownership of their work.

9. What is your approach to ensuring safety in the welding workplace?

- Enforcing the use of personal protective equipment.

- Maintaining a clean and organized work area.

- Providing proper ventilation.

- Training welders on safety procedures.

- Conducting regular safety inspections.

10. How do you prioritize and manage multiple welding projects simultaneously?

- Developing a clear project plan.

- Assigning tasks and responsibilities to team members.

- Monitoring progress and adjusting the plan as needed.

- Communicating regularly with stakeholders.

- Delegating authority and empowering team members to make decisions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Welding Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Welding Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Production Welding Supervisor is responsible for overseeing the welding operations of a manufacturing facility. They ensure that all welding is performed in accordance with the company’s quality standards and safety regulations. The key job responsibilities of a Production Welding Supervisor include:1. Managing and directing welding activities

Supervises a team of welders and ensures that they are properly trained and equipped to perform their jobs safely and efficiently.

- Assigns work to welders, including the type of weld, the materials to be welded, and the equipment to be used.

- Inspects welds to ensure that they meet the required quality standards.

2. Ensuring that welding is performed in accordance with safety regulations

Ensures that all welding operations are performed in a safe manner and in accordance with OSHA and other applicable safety regulations.

- Conducts safety inspections of welding equipment and work areas.

- Develops and implements safety procedures for welding operations.

3. Providing technical support to welders

Provides technical support to welders, including training on new welding techniques and equipment.

- Answers questions from welders about welding techniques and equipment.

- Assists welders in troubleshooting welding problems.

4. Maintaining welding equipment

Ensures that all welding equipment is properly maintained and calibrated.

- Conducts regular inspections of welding equipment.

- Performs basic maintenance on welding equipment.

5. Monitoring welding production

Monitors welding production to ensure that it meets quality and productivity goals.

- Tracks welding production data, including the number of welds produced, the quality of the welds, and the time it takes to complete welds.

- Identifies areas for improvement in welding production.

Interview Tips

To effectively prepare for an interview for a Production Welding Supervisor position, consider the following tips:Practice answering common interview questions. Some of the most common interview questions for Production Welding Supervisors include:

1. What is your experience in welding?

Highlight experience in welding, including the types of welding you have performed, the materials you have welded, and the equipment you have used.

2. What is your experience in supervising a team of welders?

Discuss experience in supervising a team of welders, including the size of the team, the types of projects you have worked on, and the challenges you have faced.

3. What is your experience in implementing safety procedures for welding operations?

Describe any experience in implementing safety procedures for welding operations, including the specific procedures you have implemented and the results you have achieved.

4. What is your experience in monitoring welding production?

Highlight any experience in monitoring welding production, including the metrics you have tracked and the improvements you have made.

5. What are your strengths and weaknesses as a Production Welding Supervisor?

Be honest about your strengths and weaknesses, and focus on how your strengths can benefit the company. For example, you might mention your experience in welding, your ability to supervise a team, or your commitment to safety.

6. What are your salary expectations?

Research the average salary for Production Welding Supervisors in your area. When asked about your salary expectations, be prepared to give a range that is in line with the market rate.

7. Do you have any questions for me?

At the end of the interview, ask the interviewer questions about the company, the position, or the industry. This shows that you are interested in the position and that you have done your research.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Welding Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.