Are you gearing up for an interview for a Pumping Station Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pumping Station Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

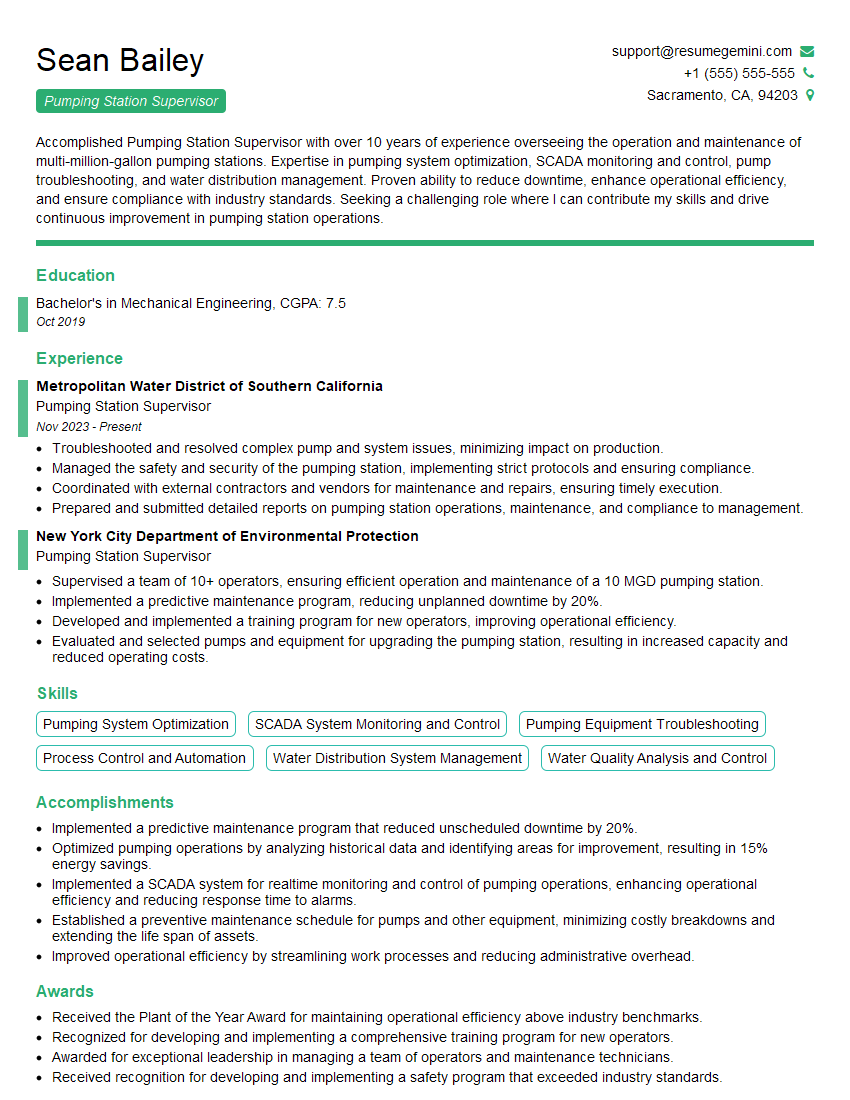

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pumping Station Supervisor

1. Describe the key responsibilities of a Pumping Station Supervisor?

The key responsibilities of a Pumping Station Supervisor include:

- Overseeing the operation and maintenance of pumping stations

- Ensuring that pumping stations are operating efficiently and in compliance with all applicable regulations

- Supervising and motivating a team of operators and maintenance technicians

- Troubleshooting and resolving any issues that arise with pumping station equipment

- Preparing and submitting reports on pumping station operations and maintenance

2. What are the different types of pumps used in pumping stations, and what are their advantages and disadvantages?

Centrifugal pumps

- Advantages: High efficiency, low maintenance, can handle a wide range of liquids

- Disadvantages: Can be expensive to purchase and install, can be noisy

Positive displacement pumps

- Advantages: Can handle viscous liquids, can create high pressures

- Disadvantages: Lower efficiency than centrifugal pumps, can be more expensive to maintain

Axial flow pumps

- Advantages: Can handle large volumes of liquid at low pressures

- Disadvantages: Less efficient than centrifugal pumps, can be more expensive to purchase and install

3. How do you calculate the head and flow rate of a pump?

The head of a pump is the height to which it can pump liquid, and the flow rate is the volume of liquid it can pump per unit time.

The head and flow rate of a pump can be calculated using the following formulas:

- Head (H) = (P2 – P1) / (ρ * g)

- Flow rate (Q) = V * A

where:

- P2 is the pressure at the outlet of the pump

- P1 is the pressure at the inlet of the pump

- ρ is the density of the liquid

- g is the acceleration due to gravity

- V is the velocity of the liquid

- A is the cross-sectional area of the pipe

4. What are the common problems that can occur with pumping stations, and how do you troubleshoot them?

Some of the common problems that can occur with pumping stations include:

- Clogged pumps

- Leaking pipes

- Electrical problems

- Mechanical problems

To troubleshoot these problems, you can follow the following steps:

- Inspect the pump for any clogs or debris

- Check the pipes for any leaks

- Inspect the electrical system for any loose connections or damaged wires

- Inspect the mechanical components of the pump for any wear or damage

5. What are the safety precautions that must be taken when working in a pumping station?

When working in a pumping station, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hard hat

- Be aware of the location of all emergency exits and shut-off valves

- Never work alone in a pumping station

- Follow all safety procedures and guidelines

6. What is your experience with managing a team of operators and maintenance technicians?

In my previous role as a Pumping Station Supervisor, I was responsible for managing a team of 10 operators and maintenance technicians. I developed and implemented a training program to ensure that all team members were properly trained on all aspects of pumping station operations and maintenance.

I also established a system for tracking employee performance and providing feedback. This system helped to improve the performance of the team and ensure that all team members were meeting expectations.

7. How do you handle a situation where a team member is not performing up to expectations?

If a team member is not performing up to expectations, I would first try to identify the root cause of the problem. This may involve talking to the team member directly, observing their work, or reviewing their performance records.

Once I have identified the root cause of the problem, I would work with the team member to develop a plan to improve their performance. This plan may include additional training, coaching, or mentoring.

If the team member is still not performing up to expectations after following the improvement plan, I may need to take disciplinary action.

8. What are your goals for the future in this role?

My goals for the future in this role are to:

- Improve the efficiency and reliability of the pumping stations under my supervision

- Reduce the cost of operating and maintaining the pumping stations

- Develop and implement new training programs for my team

- Promote a culture of safety and excellence within my team

9. What is your experience with working with SCADA systems?

In my previous role, I was responsible for the operation and maintenance of a SCADA system that monitored and controlled all of the pumping stations in the city. I was also responsible for developing and implementing new SCADA applications.

I am proficient in using a variety of SCADA software programs, including Wonderware, InTouch, and Rockwell Automation.

10. What is your understanding of the environmental regulations that apply to pumping stations?

I am familiar with the environmental regulations that apply to pumping stations, including the Clean Water Act, the Safe Drinking Water Act, and the Resource Conservation and Recovery Act.

I am also familiar with the National Pollutant Discharge Elimination System (NPDES) permit program, which regulates the discharge of pollutants from pumping stations into surface waters.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pumping Station Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pumping Station Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pumping Station Supervisor is responsible for overseeing the efficient and safe operation and maintenance of pumping stations, ensuring the continuous supply of water or wastewater services.

1. Supervision and Management

Supervises and leads a team of operators and maintenance personnel, providing training, guidance, and support.

- Creates and implements work schedules, assigns tasks, and monitors performance.

- Conducts performance evaluations and provides feedback to improve staff skills and efficiency.

2. Operations and Maintenance

Ensures the smooth and efficient operation of pumps, motors, and associated equipment.

- Monitors system performance, identifies any issues or potential problems, and takes corrective actions.

- Performs routine maintenance and repairs, including equipment inspection, lubrication, and troubleshooting.

- Maintains accurate records of maintenance activities, repairs, and equipment performance.

3. Emergency Response

Responds promptly to emergencies, such as equipment failures, power outages, or flooding.

- Assesses the situation, identifies the root cause of the problem, and takes immediate action to mitigate risks.

- Coordinates with emergency responders, utilities, and other stakeholders to ensure a swift and effective response.

4. Regulatory Compliance

Ensures compliance with all applicable regulations and industry standards.

- Monitors and interprets changing regulations and guidelines, and implements necessary changes in operations.

- Maintains accurate documentation and records to demonstrate compliance with regulatory requirements.

Interview Tips

Preparing for an interview for a Pumping Station Supervisor position requires thorough research, practice, and confidence. Consider the following tips to enhance your chances of success:

1. Research the Company and Position

Gather information about the company’s history, values, and current projects. Understanding their specific needs and the role’s responsibilities will help you tailor your answers effectively.

- Visit the company’s website, read industry news, and explore social media platforms for insights.

- Review the job description carefully and identify the key skills and experience required.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses that showcase your qualifications. Practice delivering your answers clearly and concisely.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your abilities.

- Seek feedback from friends, family, or a career counselor to refine your answers and improve your delivery.

3. Highlight Your Relevant Experience

Emphasize your experience in pump operations, maintenance, and emergency response. Quantify your accomplishments and provide specific examples of how you have contributed to successful outcomes.

- Discuss your involvement in major projects or initiatives that demonstrate your leadership and problem-solving skills.

- Mention any certifications or training programs you have completed to enhance your knowledge and expertise.

4. Demonstrate Your Commitment to Safety

Safety is paramount in pumping station operations. Highlight your understanding of industry best practices and your commitment to maintaining a safe work environment.

- Describe your experience in implementing safety protocols, conducting risk assessments, and responding to emergencies.

- Discuss your knowledge of regulatory compliance and your role in ensuring a safe and efficient operation.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pumping Station Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!