Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Puttying and Calking Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

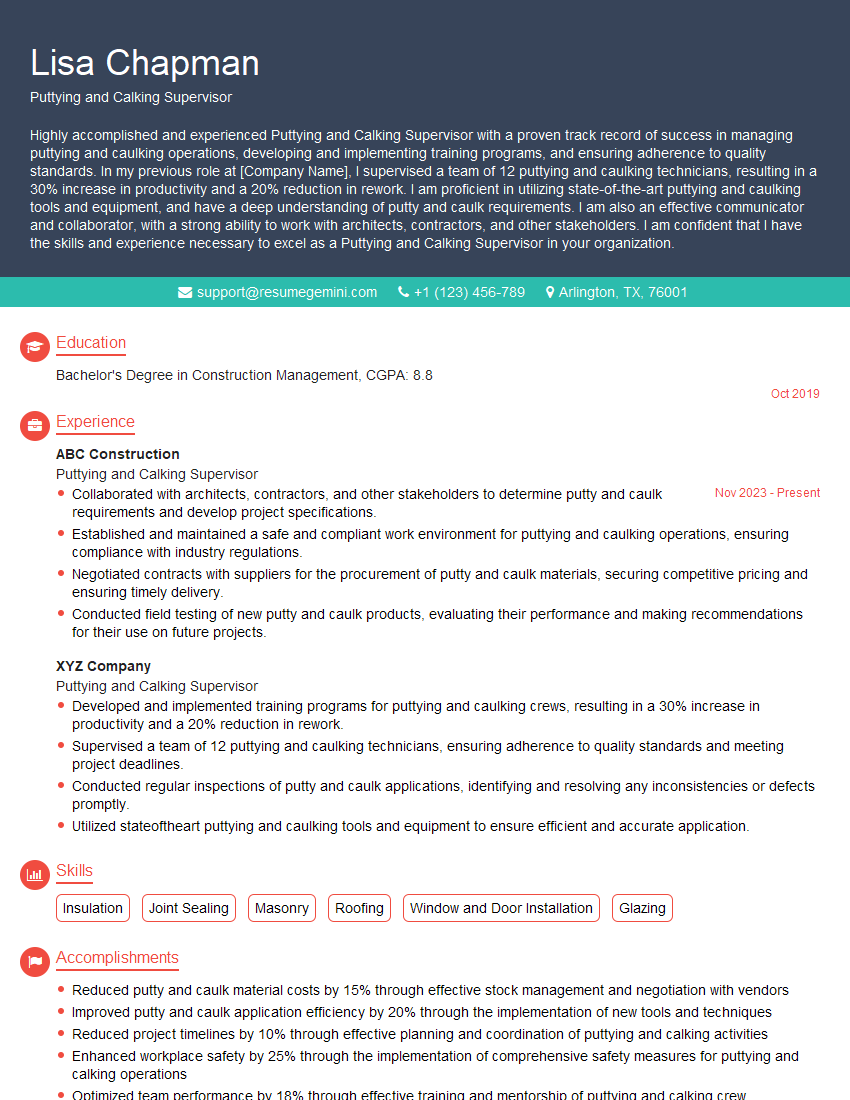

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Puttying and Calking Supervisor

1. What are the key responsibilities of a Puttying and Calking Supervisor?

As a Puttying and Calking Supervisor, I am responsible for:

- Supervising a team of puttying and calking professionals.

- Planning and scheduling work to ensure deadlines are met.

- Training and developing staff to enhance their skills and productivity.

- Inspecting work quality, adherence to specifications, and safety standards.

- Coordinating with other trades to ensure seamless project execution.

- Maintaining a safe and organized work environment.

2. How do you ensure the quality of puttying and calking work?

I follow a comprehensive quality assurance process that includes:

Inspection and Verification

- Inspecting materials for compliance with specifications.

- Verifying surface preparation and joint preparation.

- Evaluating application techniques and adherence to industry standards.

Documentation and Monitoring

- Maintaining detailed records of inspections and test results.

- Monitoring work progress and identifying areas for improvement.

- Providing feedback to the team to enhance quality and productivity.

3. What are the common challenges faced in puttying and calking and how do you overcome them?

Some common challenges include:

- Adhesive selection for specific substrates and environmental conditions.

- Overcoming surface imperfections or irregularities.

- Working in extreme temperatures or weather conditions.

To overcome these challenges, I:

- Thoroughly research and select appropriate materials for the job.

- Provide clear instructions and training to the team on proper techniques.

- Implement quality control measures throughout the process.

- Stay updated on industry best practices and technological advancements.

4. How do you stay updated on the latest industry standards and best practices?

- Attending industry conferences and workshops.

- Subscribing to trade publications and newsletters.

- Participating in online forums and discussions.

- Seeking out opportunities for professional development and training.

- Collaborating with industry experts and vendors.

5. How do you motivate and lead a team of puttying and calking professionals?

- Foster a positive and supportive work environment.

- Set clear goals and expectations.

- Provide regular feedback and recognition for good work.

- Empower team members to make decisions and take ownership.

- Encourage professional development and growth opportunities.

6. What safety measures do you implement on a puttying and calking project?

- Ensure proper ventilation and respiratory protection.

- Wear appropriate safety gear such as gloves, eye protection, and protective clothing.

- Use fall protection equipment when working at heights.

- Train team members on safe work practices and emergency procedures.

- Regularly inspect equipment and tools for safety hazards.

7. How do you handle difficult clients or project owners?

- Stay calm and professional at all times.

- Actively listen to their concerns and try to understand their perspective.

- Present solutions that meet their needs while adhering to industry standards.

- Maintain open communication and provide regular updates.

- Seek support or guidance from senior management when necessary.

8. What is your experience with different types of sealants and adhesives?

I have extensive experience with various types of sealants and adhesives, including:

- Silicone sealants

- Polyurethane sealants

- Acrylic sealants

- Butyl sealants

- Epoxies

- Polyurethanes

I am familiar with their properties, applications, and suitability for different substrates.

9. How do you ensure that puttying and calking work is done according to specifications and building codes?

- Thoroughly review project specifications and building codes.

- Develop detailed work plans and procedures.

- Provide clear instructions to the team.

- Inspect work regularly to ensure compliance.

- Work closely with architects and engineers to address any design or technical issues.

10. How do you manage project budgets and timelines?

- Develop detailed project budgets and timelines.

- Monitor progress and track expenses regularly.

- Identify potential risks and develop mitigation strategies.

- Communicate with stakeholders on budget and schedule updates.

- Seek approval for any necessary budget adjustments or timeline extensions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Puttying and Calking Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Puttying and Calking Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Puttying and Calking Supervisors are responsible for leading and supervising a team of construction workers specialized in applying putty and calk to buildings, structures, or other surfaces.

1. Plan and Organize

Develop and implement work schedules, allocate resources, and coordinate with other trades to ensure timely project completion.

- Prepare estimates and specifications for putty and calking materials and labor.

- Plan the sequence of work and determine the appropriate techniques and materials to use.

2. Supervise and Monitor

oversees the work of puttying and calking crews, providing instruction and technical guidance

- Conduct regular inspections to ensure quality and adherence to specifications.

- Monitor progress and identify potential problems or delays.

3. Train and Develop

Provide training and development opportunities to improve the skills and knowledge of puttying and calking workers.

- Develop training programs and materials to enhance workers’ skills and techniques.

- Stay updated on industry best practices and advancements in putty and calking techniques.

4. Safety and Compliance

Ensure compliance with all applicable safety regulations and industry standards.

- Maintain a safe working environment and enforce safety protocols.

- Inspect equipment and materials regularly to ensure they meet safety requirements.

Interview Tips

Preparing for an interview is critical to increase your chances of success. Here are some tips:

1. Research the Company

Learn about the company’s history, culture, and current projects. This will help you understand the company’s needs and tailor your answers accordingly.

- Visit the company’s website and read about its mission, values, and projects.

- Check industry news and articles to stay informed about the company’s latest developments.

2. Practice Your Answers

Anticipate common interview questions and prepare your responses in advance. Practice delivering your answers out loud to improve clarity and confidence.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills and experience.

- Focus on highlighting your strengths and how they align with the job requirements.

3. Ask Questions

Asking thoughtful questions at the end of the interview is an opportunity to demonstrate your interest and engagement. Prepare a few questions to ask the interviewer about the company, the position, or the industry.

- Show that you are curious about the company’s future plans and growth prospects.

- Ask about the opportunities for professional development and advancement within the organization.

4. Dress Professionally.

First impressions matter, so make sure to dress appropriately for the interview. Business casual attire is typically a safe choice.

- Choose clean, pressed clothes that are comfortable and allow you to move freely.

- Consider the company culture and industry norms when selecting your outfit.

Next Step:

Now that you’re armed with the knowledge of Puttying and Calking Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Puttying and Calking Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini