Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Remelt Furnace Expediter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

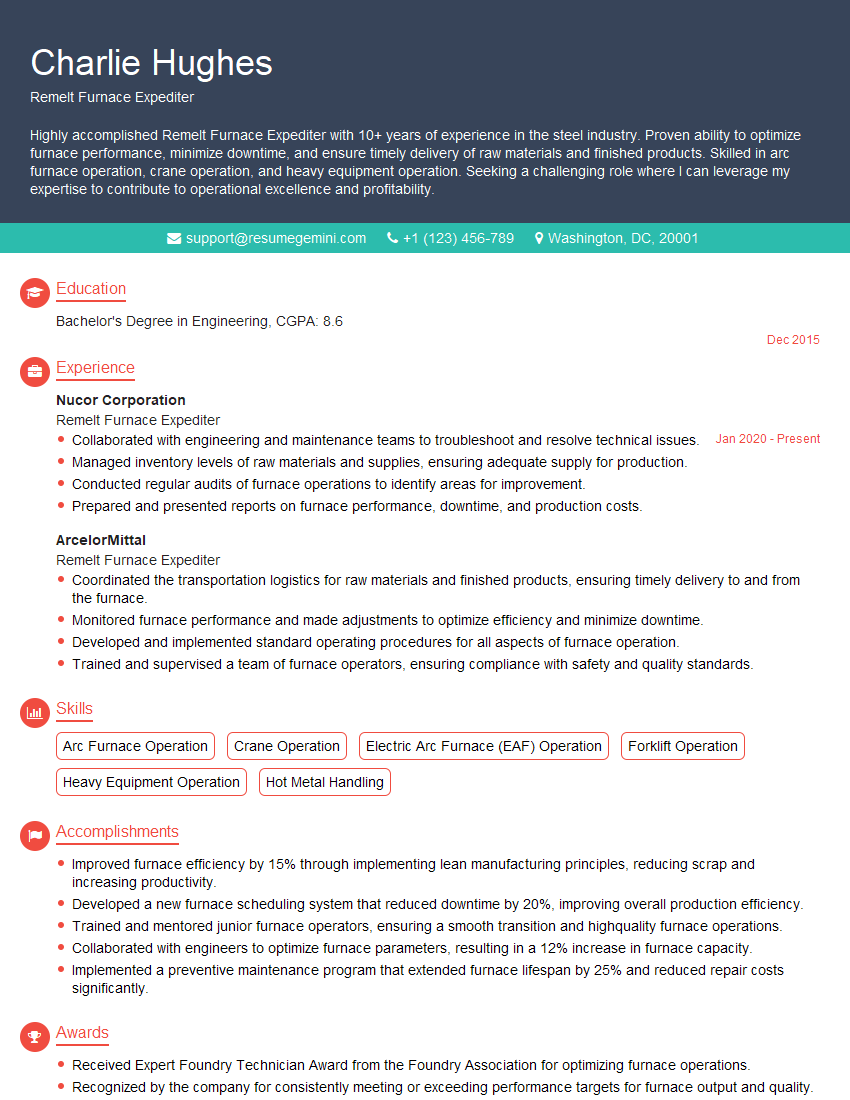

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Remelt Furnace Expediter

1. What is the role of a Remelt Furnace Expediter?

The Remelt Furnace Expediter is responsible for ensuring the smooth operation of the remelt furnace, coordinating activities to maximize productivity and minimize downtime.

- Monitor the furnace operation and identify any potential problems.

- Coordinate with the production team to ensure that materials are available and the furnace is operating at optimal capacity.

- Troubleshoot and resolve any issues that arise during the remelt process.

- Maintain records of furnace operation and performance.

2. What are the key technical skills required for a Remelt Furnace Expediter?

- A thorough understanding of the remelt furnace operation and process.

- Expertise in troubleshooting and resolving furnace issues.

- Strong communication and interpersonal skills.

- Ability to work effectively in a team environment.

- Knowledge of industry-standard safety protocols.

3. How do you prioritize tasks when multiple issues arise simultaneously?

When multiple issues arise simultaneously, I prioritize tasks based on the following criteria:

- Safety concerns.

- Potential impact on production.

- Urgency of the issue.

- Availability of resources.

4. Describe a situation where you successfully resolved a complex issue with the remelt furnace.

- Identify the issue and its potential impact.

- Describe the steps you took to troubleshoot and resolve the issue.

- Explain the outcome and any lessons learned.

5. How do you ensure that the remelt furnace is operating at optimal efficiency?

- Monitor furnace performance and identify any areas for improvement.

- Work with the production team to optimize material flow and minimize downtime.

- Implement preventive maintenance measures to reduce the risk of breakdowns.

- Stay up-to-date on industry best practices and new technologies.

6. What are your strategies for minimizing downtime during the remelt process?

- Implement preventive maintenance schedules.

- Train operators on proper furnace operation and troubleshooting.

- Maintain a stock of critical spare parts.

- Coordinate with the production team to minimize material delays.

7. How do you maintain effective communication with the production team?

- Establish clear communication channels.

- Hold regular meetings to discuss production goals and challenges.

- Provide timely updates on furnace operation and any issues that arise.

- Foster a collaborative and supportive work environment.

8. What safety protocols are essential for operating a remelt furnace?

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures.

- Monitor furnace temperature and pressure.

- Maintain a clean and organized work area.

- Be aware of potential hazards and take appropriate precautions.

9. How do you stay updated on industry best practices and new technologies related to remelt furnaces?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Connect with other professionals in the field.

- Research and evaluate new technologies that may improve furnace efficiency.

10. What are your career goals and how does this role align with them?

My career goal is to become a highly skilled and experienced Remelt Furnace Expediter. This role aligns with my goals because it provides me with the opportunity to develop my technical skills, gain valuable experience in the industry, and contribute to the success of the organization.

- I am eager to learn more about the remelt furnace process and contribute to the optimization of furnace operations.

- I believe that my skills and experience make me a suitable candidate for this role.

- I am confident that I can add value to your team and contribute to the success of your organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Remelt Furnace Expediter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Remelt Furnace Expediter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Remelt Furnace Expediter is a pivotal role in the seamless operation of a manufacturing facility, ensuring efficient coordination and timely delivery of raw materials and products within the remelting process. Key job responsibilities encompass:

1. Material Management and Logistics

The Remelt Furnace Expediter serves as the liaison between various departments, suppliers, and carriers, maintaining open communication to facilitate the smooth flow of materials.

- Coordinating the timely delivery of scrap metal, alloys, and other raw materials to the remelting furnace

- Monitoring inventory levels and initiating purchase orders as needed

2. Furnace Operation Coordination

The expediter plays a crucial role in ensuring the efficient operation of the remelting furnace, coordinating with operators to optimize production.

- Scheduling and prioritizing melt jobs based on production requirements

- Monitoring furnace performance, identifying and addressing any issues

3. Quality Control

Maintaining product quality is paramount, and the Remelt Furnace Expediter contributes to this by monitoring the remelting process and ensuring adherence to quality standards.

- Sampling and testing molten metal to verify chemical composition

- Identifying and isolating non-conforming products

4. Documentation and Reporting

Accurate and timely documentation is essential in manufacturing. The Remelt Furnace Expediter generates and maintains:

- Remelting furnace logs, capturing production data and quality control information

- Reports on material usage, furnace performance, and product quality

Interview Preparation Tips

Thoroughly preparing for an interview can significantly enhance your chances of success. Here are some tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, services, and industry trends. This demonstrates your genuine interest and prepares you to answer questions about the company’s goals.

- Visit the company’s website and LinkedIn page

- Explore industry-related news and publications

- Network with professionals in the field

2. Practice Answering Common Interview Questions

Review common interview questions and prepare thoughtful responses. Consider using the STAR method (Situation-Task-Action-Result) to structure your answers and provide specific examples:

- Tell me about a time you had to solve a complex problem.

- How do you prioritize your workload when faced with multiple deadlines?

- Can you give an example of a time when you went above and beyond in a previous role?

3. Highlight Relevant Skills and Experience

Carefully review the job description and identify the skills and experience that are most relevant to the position. Emphasize these in your resume, cover letter, and during the interview.

- Quantify your accomplishments with specific metrics

- Use industry-specific jargon and technical terms

- Prepare examples of your work that showcase your proficiency

4. Be Prepared to Ask Questions

Asking thoughtful questions demonstrates your enthusiasm and engagement. Prepare questions about the company, the role, and the industry.

- What are the company’s growth plans for the future?

- What are the specific challenges that this role is expected to address?

- How does the company invest in employee development?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Remelt Furnace Expediter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!