Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Reverberatory Furnace Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

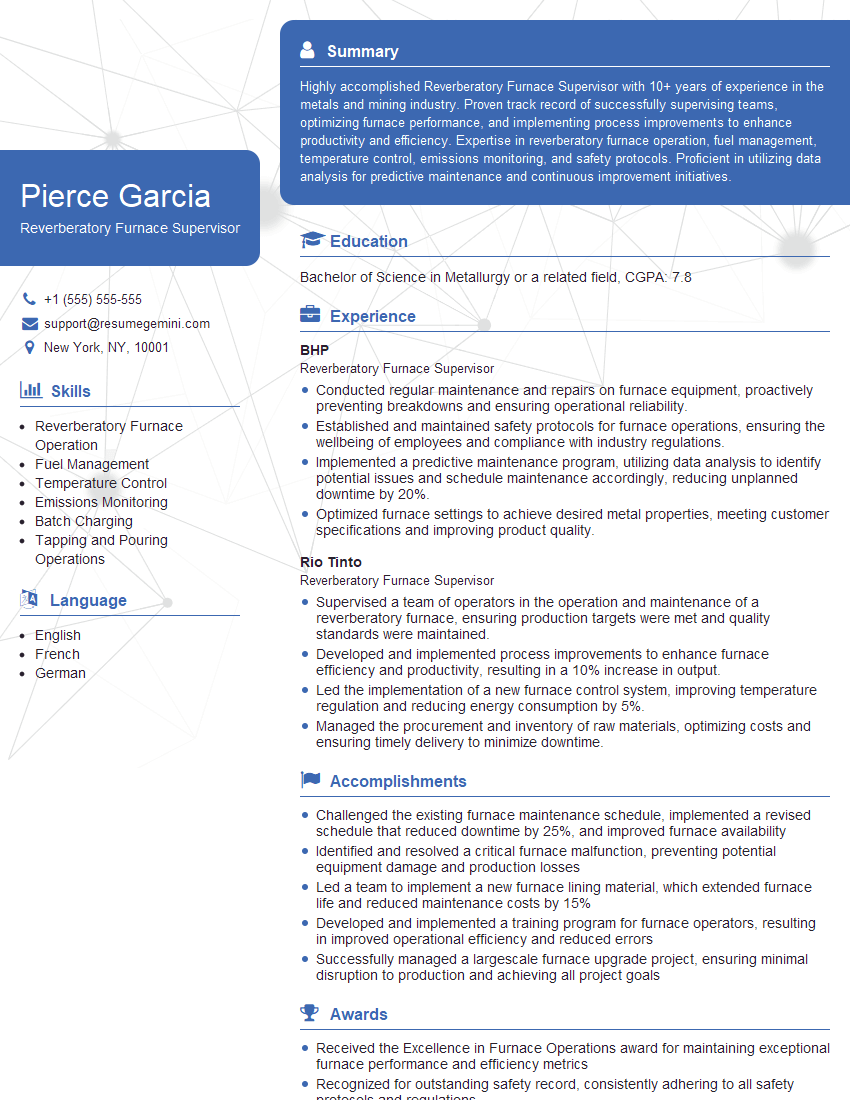

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reverberatory Furnace Supervisor

1. Describe the key responsibilities of a Reverberatory Furnace Supervisor?

As a Reverberatory Furnace Supervisor, my primary responsibilities include:

- Overseeing the operation and maintenance of reverberatory furnaces

- Monitoring furnace performance and adjusting process parameters to optimize production

- Ensuring adherence to safety protocols and environmental regulations

- Supervising and training furnace operators

- Troubleshooting and resolving operational issues

2. Explain the principles of reverberatory furnace operation?

Heat Transfer

- Heat is transferred from the combustion zone to the charge through radiation

- The arched roof of the furnace acts as a radiant heat exchanger

Fuel Combustion

- Burners are located at one end of the furnace

- Fuel and air are mixed to create a flame that impinges on the charge

Charge Processing

- Charge is typically introduced through a charging door

- Material is heated and melted by the radiant heat

3. What are the common challenges faced in reverberatory furnace operations?

Some common challenges include:

- Maintaining optimal furnace temperature

- Controlling slag formation and accumulation

- Preventing refractory damage

- Minimizing emissions and environmental impact

- Ensuring safety and minimizing downtime

4. How do you optimize reverberatory furnace performance?

Key strategies for optimization include:

- Monitoring and adjusting fuel flow and air ratio

- Controlling furnace temperature and residence time

- Minimizing slag buildup through fluxing and tapping

- Regular maintenance and inspection of equipment

- Implementing energy-efficient practices

5. Explain the importance of safety in reverberatory furnace operations?

Safety is paramount due to the following risks:

- High temperatures and molten metal

- Flammable fuels and gases

- Potential for explosions and fires

- Toxic emissions and fumes

Safety measures include:

- Adhering to operating procedures

- Wearing appropriate personal protective equipment

- Maintaining a clean and organized work area

- Training and educating employees

- Regular safety inspections and audits

6. Describe the role of refractory materials in reverberatory furnaces?

Refractory materials are essential for:

- Containing molten metal and slag

- Protecting the furnace shell from heat damage

- Minimizing heat loss

- Preventing contamination of molten metal

Common refractory materials include:

- Magnesia-chrome bricks

- Fireclay bricks

- Castable refractories

7. Explain how you troubleshoot common reverberatory furnace problems?

Troubleshooting steps typically include:

- Identifying the problem and its symptoms

- Reviewing operating conditions and logs

- Inspecting the furnace and its components

- Consulting with technical experts or manufacturers

- Implementing corrective actions and monitoring results

8. Describe the maintenance procedures for reverberatory furnaces?

Regular maintenance tasks include:

- Inspecting and repairing refractory linings

- Cleaning and calibrating burners

- Replacing worn or damaged components

- Lubricating moving parts

- Monitoring and repairing electrical and instrumentation systems

9. How do you train and develop furnace operators?

Training programs typically cover:

- Furnace operating principles and procedures

- Safety protocols and emergency response

- Equipment maintenance and troubleshooting

- Process monitoring and quality control

- Environmental regulations and compliance

10. Explain your understanding of industry best practices for reverberatory furnace operations?

Best practices include:

- Adhering to manufacturer’s guidelines and industry standards

- Implementing energy-efficient technologies

- Minimizing environmental impact

- Continuous process improvement and optimization

- Regular training and certification of operators

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reverberatory Furnace Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reverberatory Furnace Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Reverberatory Furnace Supervisor is responsible for overseeing the safe and efficient operation of a reverberatory furnace. The key responsibilities of this role include:

1. Furnace Operations

Ensuring that the furnace is operating within safe operating parameters

- Monitoring furnace temperatures, pressures, and other process variables

- Adjusting furnace settings to maintain optimal operating conditions

- Troubleshooting and resolving furnace operational issues

2. Raw Material Management

Ensuring that the furnace is supplied with the correct raw materials in the correct quantities

- Inspecting raw materials for quality and quantity

- Preparing raw materials for furnace charging

- Managing raw material inventory

3. Product Quality Control

Ensuring that the furnace is producing products that meet the required specifications

- Sampling and testing furnace products

- Analyzing product test results and taking corrective action as needed

- Maintaining product quality records

4. Equipment Maintenance

Ensuring that the furnace and associated equipment is properly maintained

- Inspecting and servicing equipment on a regular basis

- Performing minor repairs and maintenance tasks

- Coordinating major repairs and maintenance activities

5. Safety and Environmental Compliance

Ensuring that the furnace is operated in a safe and environmentally compliant manner

- Following all safety procedures

- Monitoring environmental emissions and taking corrective action as needed

- Maintaining environmental compliance records

Interview Tips

To ace your interview for a Reverberatory Furnace Supervisor position, it is important to:

1. Research the company and the position

This will show the interviewer that you are serious about the job and that you have taken the time to learn about the company. Research the following details:

- The company’s history, products, and services

- The specific role of a Reverberatory Furnace Supervisor within the company

- Any recent news or developments related to the company or the industry

2. Quantify your accomplishments

When describing your experience and accomplishments, be sure to use specific numbers and metrics. This will help the interviewer to understand the impact of your work and how you have contributed to the success of your previous employers.

- Example: Instead of saying “I managed a team of furnace operators,” say “I managed a team of 10 furnace operators and increased productivity by 15% while reducing downtime by 20%.”

3. Be prepared to answer technical questions

The interviewer will likely ask you questions about your technical knowledge and experience. Be prepared to discuss the following topics:

- Reverberatory furnace design and operation

- Metallurgical processes

- Quality control techniques

- Safety and environmental regulations

4. Emphasize your leadership and communication skills

A Reverberatory Furnace Supervisor is a leadership role. The interviewer will be looking for candidates who have strong leadership skills and who can effectively communicate with both technical and non-technical audiences.

- Example: Highlight your experience in motivating and leading teams, resolving conflicts, and communicating complex technical information to non-technical audiences.

5. Be yourself

The most important thing is to be yourself and let the interviewer get to know the real you. Be honest about your skills and experience, and be confident in your abilities. The interviewer will be able to tell if you are not being genuine, so it is important to be yourself and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Reverberatory Furnace Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!