Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sandblasting Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

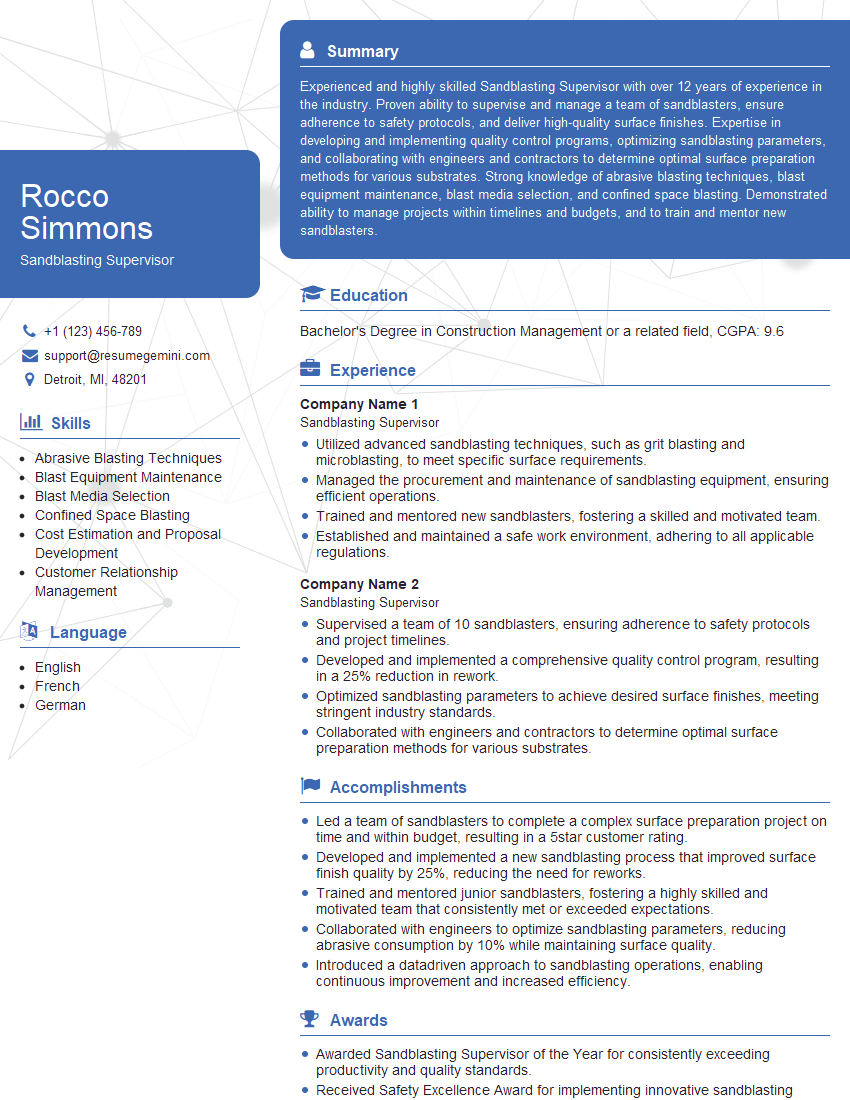

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sandblasting Supervisor

1. What are the different types of abrasive materials used in sandblasting and their applications?

- Glass beads: Used for delicate surfaces, such as fiberglass and aluminum, as they produce a fine finish.

- Sand: Commonly used for general purpose sandblasting, provides a medium-coarse finish.

- Soda: Environmentally friendly, used for removing paint, rust, and graffiti without damaging the underlying surface.

- Steel shot: Suitable for heavy-duty applications, such as removing rust and mill scale.

- Walnut shells: Biodegradable, used for sensitive surfaces, such as wood and stone.

2. Describe the factors that affect the surface finish in sandblasting?

Abrasive Media Selection

- Material, size, and shape of the abrasive

Nozzle Parameters

- Nozzle size and shape

- Distance from the surface

- Angle of impact

Air Pressure and Flow Rate

- Higher air pressure increases the impact force

- Higher air flow rate carries more abrasive particles

Surface Characteristics

- Material, hardness, and roughness of the surface

3. How do you ensure the safety of personnel and equipment during sandblasting operations?

- PPE: Provide proper personal protective equipment, including respirators, gloves, and eye/ear protection.

- Containment: Set up physical barriers or enclosures to prevent abrasive particles from escaping.

- Ventilation: Ensure adequate ventilation to remove dust and fumes generated during sandblasting.

- Equipment Maintenance: Regularly inspect and maintain sandblasting equipment to ensure safe operation.

- Training: Train operators on proper handling and safety procedures.

4. What techniques do you use to inspect and assess the quality of sandblasted surfaces?

- Visual Inspection: Examine the surface for any imperfections, such as pitting, gouging, or uneven finish.

- Surface Profile Measurement: Use a surface profile gauge to measure the roughness of the surface.

- Non-Destructive Testing: Employ techniques like ultrasonic testing or dye penetrant testing to detect скрытые дефекты or cracks.

- Adhesion Testing: Conduct tests to evaluate the bond strength between the coating and the sandblasted surface.

5. How do you handle and dispose of spent abrasive materials and blasting waste?

- Collection: Use dust collectors or containment systems to collect spent abrasive materials and blasting waste.

- Waste Characterization: Determine the characteristics of the waste to identify appropriate disposal methods.

- Disposal: Dispose of waste according to local regulations and guidelines, which may include recycling, landfilling, or incineration.

- Recordkeeping: Maintain accurate records of waste handling and disposal practices.

6. What are the potential hazards associated with sandblasting and how do you mitigate them?

- Silica Dust: Use respirators and ventilation to prevent inhalation of harmful silica dust.

- Abrasive Particles: Wear appropriate PPE to protect against impact from abrasive particles.

- Noise: Implement noise control measures, such as silencers and ear protection.

- Compressed Air: Ensure safe handling of compressed air lines and equipment.

- Electrical Hazards: Follow electrical safety guidelines and inspect equipment regularly.

7. What are the advantages of using sandblasting over other surface preparation methods?

- Efficient Removal: Effectively removes contaminants, rust, and old paint from various surfaces.

- Customizable: Allows for precise control over surface finish through the selection of abrasive materials and parameters.

- Preparation for Coatings: Creates a clean and ideal surface for subsequent coating applications, ensuring good adhesion.

- Corrosion Resistance: Removes corrosion and prepares surfaces for protective coatings, extending their lifespan.

- Aesthetic Enhancements: Can be used for decorative purposes to achieve specific surface textures and finishes.

8. How do you optimize sandblasting operations for efficiency and cost-effectiveness?

- Process Optimization: Fine-tune parameters such as air pressure, nozzle size, and abrasive flow rate to maximize efficiency.

- Equipment Selection: Choose appropriate sandblasting equipment based on the job requirements and surface area.

- Abrasive Management: Control abrasive consumption and minimize waste through proper recycling and reuse techniques.

- Labor Optimization: Train operators effectively and implement efficient work practices to reduce labor costs.

- Maintenance and Inspection: Regularly maintain equipment and conduct inspections to prevent breakdowns and ensure optimal performance.

9. What are the latest advancements in sandblasting technology?

- Automated Sandblasting: Robotic or automated systems for increased precision and efficiency.

- Environmentally Friendly Abrasives: Biodegradable and non-toxic abrasives to reduce environmental impact.

- Laser Sandblasting: Laser-guided sandblasting for high-precision and intricate designs.

- Waterjet Sandblasting: Combination of water and abrasives for reduced dust and improved surface finish.

- Advanced Nozzle Designs: Improved nozzle designs for enhanced abrasive flow control and efficiency.

10. How do you stay updated on the latest industry best practices and regulations related to sandblasting?

- Conferences and Seminars: Attend industry events to learn about new techniques and advancements.

- Trade Publications: Subscribe to industry magazines and journals for up-to-date information.

- Online Resources: Utilize online platforms and websites for research and knowledge sharing.

- Networking: Connect with other sandblasting professionals and exchange ideas.

- Regulatory Compliance: Stay informed about current regulations and guidelines to ensure compliance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sandblasting Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sandblasting Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sandblasting Supervisors oversee and manage sandblasting operations, ensuring adherence to safety protocols and project specifications.

1. Safety Management

Ensure the safety of personnel by implementing and enforcing safety protocols, providing training, and conducting regular safety inspections.

- Develop and implement safety plans and procedures.

- Conduct safety orientations and training programs.

2. Project Management

Oversee sandblasting projects, including planning, scheduling, and cost control, to ensure timely and efficient completion.

- Develop and manage project plans and schedules.

- Coordinate with project stakeholders, including clients, contractors, and engineers.

3. Quality Control

Monitor sandblasting operations to ensure adherence to specifications, inspect surfaces, and identify potential defects.

- Establish and maintain quality standards for surface preparation.

- Conduct surface inspections before and after sandblasting.

4. Equipment and Material Management

Manage sandblasting equipment and materials, including procurement, maintenance, and inventory control.

- Select and procure sandblasting equipment and materials.

- Monitor equipment performance and schedule maintenance.

Interview Tips

Preparing for a Sandblasting Supervisor interview requires thorough knowledge of the industry and key responsibilities. Here are some tips to help you ace your interview:

1. Research the Company and Position

Familiarize yourself with the company’s values, mission, and current projects. Understand the specific responsibilities and requirements of the Sandblasting Supervisor role.

2. Highlight Your Safety Expertise

Safety is paramount in sandblasting operations. Emphasize your experience in developing and implementing safety protocols, conducting training, and maintaining a safe work environment.

3. Showcase Your Project Management Skills

Highlight your ability to plan, schedule, and execute sandblasting projects efficiently. Share examples of your experience in coordinating with stakeholders and managing multiple projects simultaneously.

4. Demonstrate Your Technical Knowledge

Discuss your knowledge of sandblasting techniques, surface preparation standards, and quality control procedures. Showcase your understanding of different abrasive materials and their applications.

5. Be Prepared to Discuss Safety Regulations

Familiarity with safety regulations and industry best practices is crucial for Sandblasting Supervisors. Be prepared to discuss your understanding of OSHA regulations and relevant industry standards.

6. Practice Your Communication Skills

Sandblasting Supervisors must effectively communicate with diverse stakeholders, including clients, contractors, and engineers. Demonstrate your ability to convey technical information clearly and confidently.

7. Ask Informed Questions

Prepare insightful questions to ask the interviewer. This shows your interest in the company and the position and provides an opportunity to clarify any uncertainties.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Sandblasting Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.