Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sewing Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sewing Supervisor so you can tailor your answers to impress potential employers.

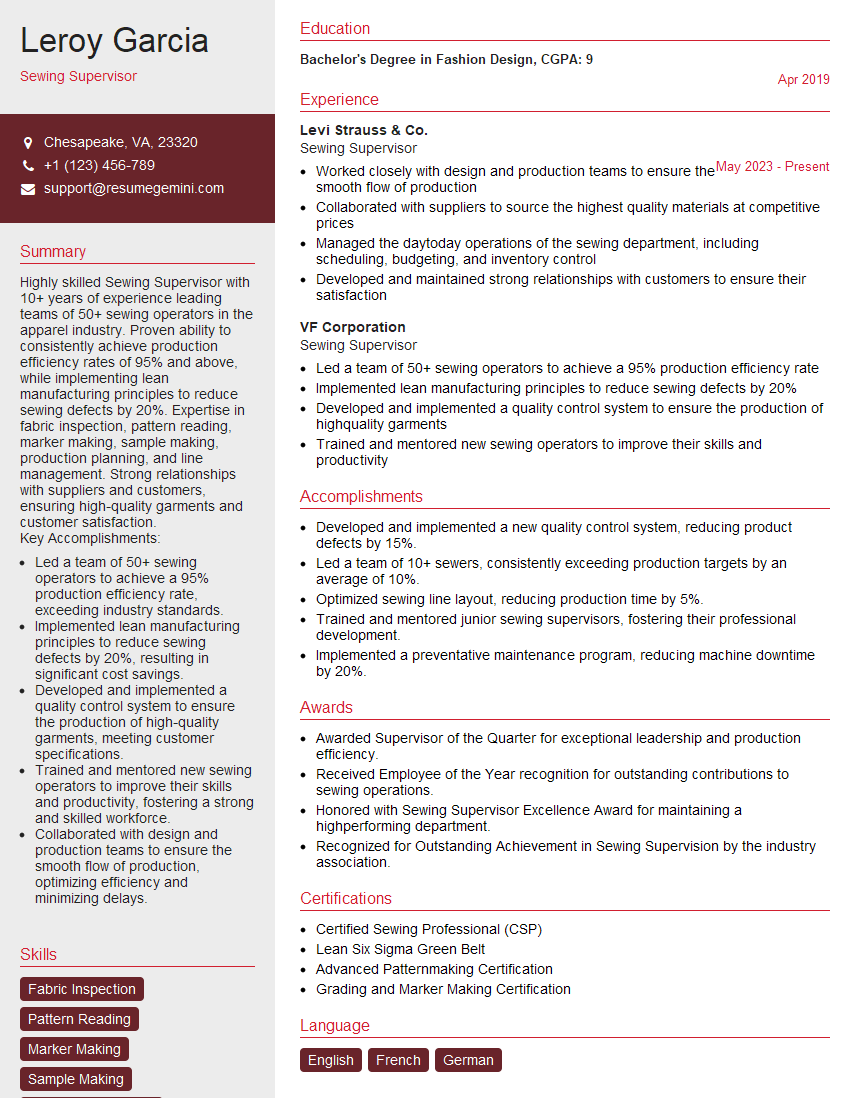

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sewing Supervisor

1. What is the significance of effective fabric utilization in garment manufacturing?

Effective fabric utilization is crucial in garment manufacturing as it directly impacts:

- Cost-saving: Minimizing fabric waste reduces overall production costs.

- Waste reduction: Proper utilization promotes environmental sustainability by reducing fabric disposal.

- Improved efficiency: Optimized fabric cutting and planning result in more efficient production processes.

- Increased profitability: By reducing waste and optimizing fabric usage, manufacturers can increase their profit margins.

2. Explain the key elements of a garment specification sheet.

Technical Specifications

- Fiber content and fabric properties

- Stitch specifications and seam allowances

- Garment measurements and tolerances

- Buttons, zippers, and hardware details

Design Specifications

- Style and silhouette

- Neckline, sleeve, and hem details

- Color swatches and prints

- Target market and intended user

Quality Control Standards

- Inspection criteria and acceptable defect levels

- Testing requirements (e.g., shrinkage, colorfastness)

- Packaging and labeling specifications

3. How do you ensure the quality of sewing operations on the production floor?

To ensure sewing quality, I implement various measures:

- Training and skill assessment: Train and assess operators regularly to maintain high standards.

- Standard operating procedures (SOPs): Establish clear SOPs for each sewing operation to minimize errors.

- Regular quality checks: Conduct random and scheduled inspections to identify and rectify any quality issues promptly.

- Employee empowerment: Encourage operators to report quality concerns and engage them in continuous improvement initiatives.

- Equipment maintenance: Ensure sewing machines and equipment are regularly serviced and calibrated for optimal performance.

4. Describe your experience in managing a team of sewing operators.

In my previous role, I successfully managed a team of 50+ sewing operators:

- Delegation and accountability: I effectively delegated tasks and held operators accountable for their assignments.

- Motivation and recognition: I fostered a positive and motivating work environment by recognizing achievements and providing feedback.

- Conflict resolution: I skillfully handled conflicts and disputes within the team to maintain a harmonious and productive atmosphere.

- Skill development: I organized training programs to enhance operators’ skills and knowledge.

- Performance monitoring: I regularly tracked and evaluated operator performance to identify areas for improvement.

5. How do you optimize production efficiency in the sewing department?

To optimize efficiency, I focus on:

- Line balancing: Ensuring an even distribution of workload among operators to minimize downtime.

- Workstation organization: Designing ergonomic workstations to minimize operator fatigue and improve productivity.

- Process streamlining: Identifying and eliminating bottlenecks in the production process to reduce lead times.

- Preventive maintenance: Scheduling regular maintenance to prevent equipment failures and minimize disruptions.

- Continuous improvement: Regularly reviewing and implementing process improvements to enhance overall efficiency.

6. What are your strategies for reducing sewing defects?

To minimize sewing defects, I implement several strategies:

- Operator training: I provide thorough training to ensure operators understand the importance of quality and minimize errors.

- Quality inspections: I establish a comprehensive quality inspection system to identify and rectify defects at various stages of production.

- Root cause analysis: I investigate the root causes of defects and implement corrective actions to prevent their recurrence.

- Supplier evaluation: I evaluate fabric and thread suppliers to ensure they meet our quality standards.

- Continuous improvement: I regularly monitor defect rates and implement measures to reduce their frequency.

7. How do you handle production delays and meet tight deadlines?

To manage production delays and meet deadlines effectively, I prioritize the following:

- Communication: I maintain clear and timely communication with stakeholders to keep them informed of production status.

- Prioritization: I identify the most critical orders and allocate resources accordingly to ensure on-time delivery.

- Resource optimization: I explore alternative production methods or equipment to minimize delays.

- Supplier negotiation: I negotiate with suppliers for expedited deliveries of essential materials or components.

- Overtime management: I utilize overtime judiciously to catch up on production when necessary.

8. Describe your experience in implementing lean manufacturing principles in a sewing operation.

In my previous role, I successfully implemented lean principles in the sewing operation, resulting in significant improvements:

- Waste reduction: I identified and eliminated non-value-added activities, such as excessive material handling.

- Process flow optimization: I re-designed the production layout to improve material flow and reduce production time.

- Inventory control: I implemented a just-in-time inventory system to minimize inventory holding costs and enhance production efficiency.

- Employee engagement: I involved operators in the improvement process to gather valuable insights and foster a culture of continuous improvement.

- Performance tracking: I established performance metrics and regularly tracked progress to identify areas for further optimization.

9. How do you ensure compliance with safety regulations in the sewing department?

To maintain a safe work environment, I implement the following measures:

- Safety training: I conduct regular safety training sessions for all operators, covering machine operation, handling hazardous materials, and emergency procedures.

- Hazard identification: I identify and assess potential hazards in the workplace and implement appropriate control measures.

- Machine guarding: I ensure that sewing machines are properly guarded to prevent accidents.

- Personal protective equipment: I provide and enforce the use of personal protective equipment, such as safety glasses and gloves.

- Emergency preparedness: I establish clear emergency evacuation plans and train operators on appropriate responses.

10. What are the key challenges you anticipate in this role and how would you address them?

I understand that every role comes with unique challenges, and I am confident in my ability to address them:

- Production targets: I am prepared to work diligently and implement strategies to optimize production efficiency and meet targets.

- Maintaining quality standards: I am committed to ensuring high-quality sewing operations through robust quality control measures and operator training.

- Team management: I am adept at motivating, leading, and training a team of sewing operators to achieve collective goals.

- Cost control: I understand the importance of cost optimization and will explore ways to minimize waste and improve fabric utilization.

- Continuous improvement: I am keen on identifying and implementing process improvements to enhance overall productivity and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sewing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sewing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As the Sewing Supervisor, you play a crucial role in ensuring efficient and high-quality garment production. Your key responsibilities involve:

1. Team Management and Supervision

Lead and supervise a team of sewing operators, ensuring they follow production schedules and quality standards.

- Assign tasks, set goals, and provide guidance to operators.

- Monitor operator performance, identify areas for improvement, and provide necessary training.

2. Quality Control and Inspection

Implement and maintain quality control systems to ensure garments meet specifications and customer requirements.

- Establish and enforce quality standards for materials, garments, and production processes.

- Inspect garments throughout the production cycle, identifying and rectifying defects.

3. Production Planning and Optimization

Work closely with other departments to optimize production processes and increase efficiency.

- Develop and implement strategies to improve workflow and reduce downtime.

- Analyze production data to identify bottlenecks and suggest solutions.

4. Materials Management

Ensure there is adequate supply of materials for production, managing inventory and coordinating with suppliers.

- Monitor material usage and inventory levels, placing orders as necessary.

- Work with quality control to ensure materials meet specifications.

Interview Tips

To ace the interview for the Sewing Supervisor position, here are some tips:

1. Research the Company and Role

Thoroughly research the company, its values, and its products. Also, familiarize yourself with the specific responsibilities of the Sewing Supervisor role.

- Use the company website, LinkedIn, and industry publications to gather information.

- Prepare questions that demonstrate your understanding of the company and the role.

2. Highlight Your Technical Expertise

Showcase your technical knowledge of sewing techniques, quality control processes, and production management. Provide specific examples of your experience.

- Describe how you have implemented quality control systems that resulted in improved product quality.

- Share strategies you have used to optimize production processes and increase efficiency.

3. Emphasize Your Leadership and Communication Skills

Supervising a team requires strong leadership and communication skills. Highlight your ability to motivate and guide others, and to build effective working relationships with colleagues.

- Give examples of how you have successfully managed a team and resolved conflicts.

- Describe how you have effectively communicated with colleagues from different backgrounds.

4. Prepare for Behavioral Interview Questions

Many interviews will include behavioral questions that ask you to describe specific situations in your previous experiences. For example, they may ask about a time you faced a production challenge or handled a difficult employee.

- Use the STAR method (Situation, Task, Action, Result) to answer these questions.

- Focus on providing detailed and specific examples that demonstrate your skills and abilities.

5. Dress Professionally and Punctually

First impressions matter, so dress professionally and arrive for your interview on time. This shows that you respect the interviewer and are serious about the position.

Next Step:

Now that you’re armed with the knowledge of Sewing Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sewing Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini