Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Shuttle Fitting Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Shuttle Fitting Supervisor so you can tailor your answers to impress potential employers.

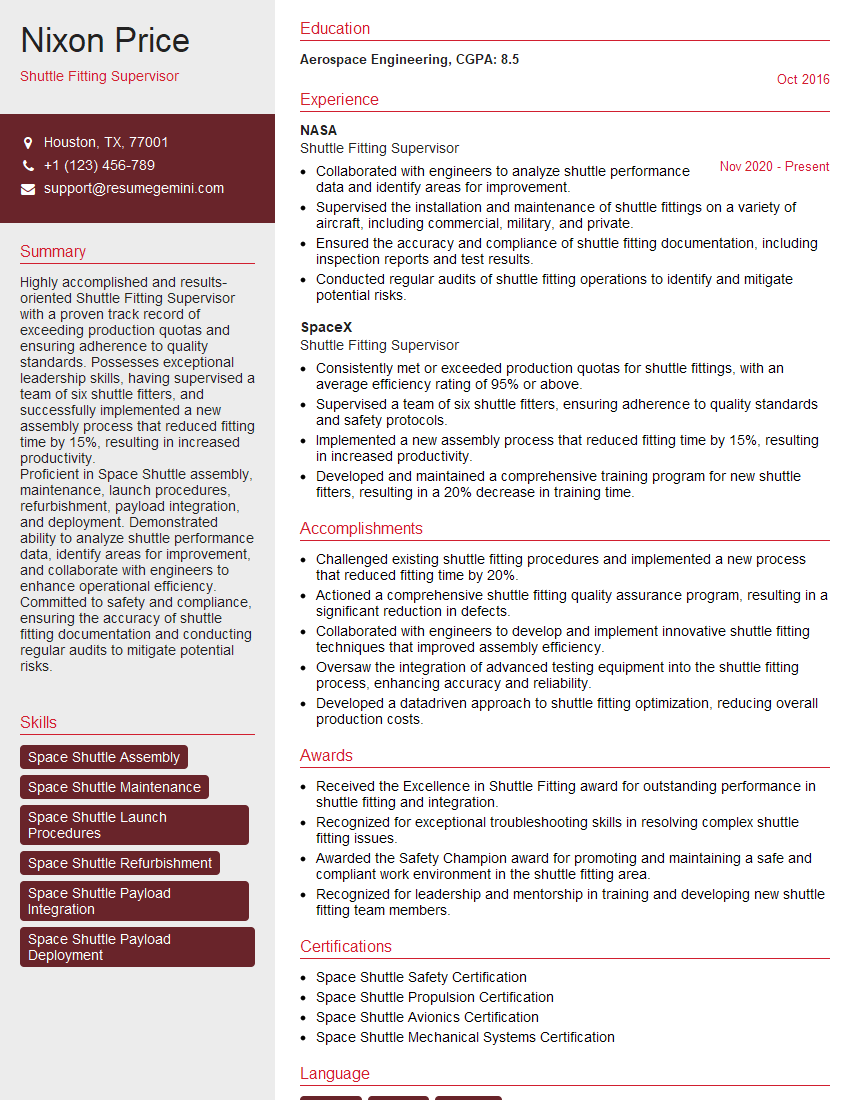

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shuttle Fitting Supervisor

1. What is the importance of proper shuttle fitting for smooth loom operations?

Proper shuttle fitting is crucial for smooth loom operations for several reasons:

- Optimizing Weaving Efficiency: Correctly fitted shuttles ensure proper timing and alignment during the weaving process, minimizing yarn breakage and maximizing fabric output.

- Preventing Shuttle Accidents: A poorly fitted shuttle can cause it to dislodge or fly off the loom, creating a safety hazard for operators and causing production delays.

- Reducing Maintenance Costs: When shuttles are fitted properly, they are less likely to damage the loom components, reducing the need for frequent repairs and maintenance.

- Improving Fabric Quality: Properly fitted shuttles ensure even yarn tension and uniform weaving, resulting in higher-quality fabric with fewer defects.

2. Describe the key steps involved in fitting a shuttle to a loom.

Pre-Fitting Inspection:

- Inspect the shuttle body for any damages or cracks.

- Check the shuttle tip and bobbin for proper alignment.

- Verify the condition of the shuttle drive and carrier.

Fitting the Shuttle:

- Place the shuttle on the shuttle drive and secure it with the appropriate tension.

- Adjust the shuttle carrier to align the shuttle properly with the loom’s raceboard.

- Install the bobbin into the shuttle and ensure it rotates smoothly.

Post-Fitting Adjustments:

- Fine-tune the shuttle’s timing using the timing device.

- Check the shuttle for any vibrations or noise.

- Conduct a test run to ensure smooth operation.

3. What are the common problems encountered during shuttle fitting and how do you address them?

Common shuttle fitting problems and their solutions include:

- Shuttle misalignment: Adjust the shuttle carrier and timing device to ensure proper alignment.

- Shuttle vibrations: Inspect the shuttle drive, carrier, and bobbin for any damage or misalignment.

- Shuttle sticking: Clean and lubricate the shuttle components, check the tension settings.

- Bobbin slipping: Tighten the bobbin holder and check the bobbin for proper winding.

- Shuttle breakage: Inspect the shuttle body for cracks or damage, replace if necessary.

4. How do you ensure the accuracy of the shuttle timing?

To ensure the accuracy of shuttle timing:

- Use a timing device to measure the shuttle’s dwell and pick times.

- Fine-tune the timing adjustments based on the desired fabric quality and loom speed.

- Monitor the loom’s performance and make adjustments as needed to maintain optimal timing.

- Regularly calibrate the timing device according to the manufacturer’s recommendations.

5. What are the best practices for maintaining shuttle assemblies to maximize their lifespan?

- Regular Cleaning: Regularly clean shuttles, bobbins, and shuttle carriers to remove any debris or lint that can cause friction or damage.

- Lubrication: Lubricate moving parts of the shuttle, such as the drive and bobbin holder, to reduce friction and wear.

- Inspection and Repair: Periodically inspect shuttles for any cracks or damage, and replace or repair them promptly.

- Proper Storage: When not in use, store shuttles in a dry and protected environment to prevent rust or corrosion.

6. How do you optimize shuttle fitting for different types of looms and fabrics?

To optimize shuttle fitting for different types of looms and fabrics:

- Loom Specifications: Consider the specific requirements of the loom, such as shuttle size, timing, and carrier design.

- Fabric Type: Adjust the shuttle fitting parameters based on the fabric’s weight, texture, and weave structure.

- Yarn Quality: Take into account the yarn’s tension, thickness, and compatibility with the shuttle.

- Production Goals: Optimize the shuttle fitting to meet production targets for efficiency, fabric quality, and loom uptime.

7. What is the importance of training loom operators on proper shuttle fitting techniques?

- Improved Efficiency: Trained operators can perform shuttle fitting quickly and accurately, minimizing downtime and maximizing productivity.

- Reduced Maintenance Costs: Proper fitting techniques prevent premature shuttle wear and damage, resulting in lower maintenance costs.

- Enhanced Fabric Quality: Operators can identify and correct potential fitting issues, leading to improved fabric quality and fewer defects.

- Safety: Training reduces the risk of shuttle accidents caused by improper fitting.

8. How do you stay updated on the latest shuttle fitting techniques and equipment advancements?

- Industry Seminars and Workshops: Attend industry events to learn about new techniques and best practices.

- Manufacturer Training: Participate in training programs provided by shuttle manufacturers.

- Trade Publications and Online Resources: Read industry publications and online articles to stay informed about the latest developments.

- Networking with Peers: Exchange knowledge and ideas with other shuttle fitting professionals.

9. Describe a situation where you successfully resolved a challenging shuttle fitting issue.

Example:

I encountered a shuttle fitting issue where the shuttle was misaligning during the weaving process, resulting in yarn breakage and fabric defects. I conducted a thorough inspection and discovered that the shuttle carrier was slightly bent. I carefully adjusted the carrier, ensuring proper alignment with the raceboard. After making these adjustments, the shuttle alignment was restored, yarn breakage was eliminated, and fabric quality improved significantly.

10. How do you ensure the quality of shuttle fitting in a high-volume production environment?

- Standardized Procedures: Implement clear and standardized shuttle fitting procedures to ensure consistency.

- Regular Inspections: Conduct regular inspections of shuttles and looms to identify and correct potential issues.

- Quality Assurance Team: Establish a dedicated quality assurance team to monitor and oversee shuttle fitting operations.

- Training and Monitoring: Provide thorough training to loom operators and monitor their performance to ensure adherence to proper techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shuttle Fitting Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shuttle Fitting Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shuttle Fitting Supervisors play a crucial role in ensuring the smooth functioning of aircraft manufacturing and assembly operations. Their key responsibilities include:

1. Leading and Supervising Teams

Supervising and directing teams of fitters, assemblers, and other personnel involved in aircraft shuttle fitting and assembly processes.

2. Maintaining Quality and Safety Standards

Enforcing strict adherence to quality and safety standards, ensuring that all fitting and assembly procedures are carried out accurately and in compliance with regulations.

3. Monitoring Production Processes

Overseeing production processes, monitoring progress, identifying bottlenecks, and implementing corrective actions to enhance efficiency and productivity.

4. Coordinating with Other Departments

Collaborating with engineering, design, and quality control departments to ensure seamless flow of information and materials, resolving any issues promptly.

Interview Tips

Preparing thoroughly for an interview can significantly improve your chances of success. Here are some key tips to help you ace your interview for a Shuttle Fitting Supervisor position:

1. Research the Company and Role

Familiarize yourself with the company’s history, culture, and current projects. Research the specific responsibilities of the Shuttle Fitting Supervisor role to gain a comprehensive understanding of the expectations.

- Example: Visit the company’s website, read industry news and articles, and connect with current or former employees on LinkedIn.

2. Highlight Relevant Experience and Skills

Showcase your relevant experience and skills that align with the job requirements. Quantify your accomplishments and provide specific examples to demonstrate your abilities.

- Example: Highlight your experience in supervising and motivating teams in a manufacturing or assembly environment.

3. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that showcase your knowledge, skills, and abilities. Practice answering these questions clearly and concisely.

- Example: Prepare for questions related to your leadership style, quality control measures, and experience in managing large-scale projects.

- Example: Maintain eye contact, ask clarifying questions, and summarize key points to show that you are engaged and understanding.

4. Practice Active Listening and Communication

During the interview, demonstrate active listening skills by paying attention to the interviewer’s questions and responding with thoughtful and relevant answers. Communicate your ideas and opinions clearly and confidently.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shuttle Fitting Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.