Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sign Shop Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

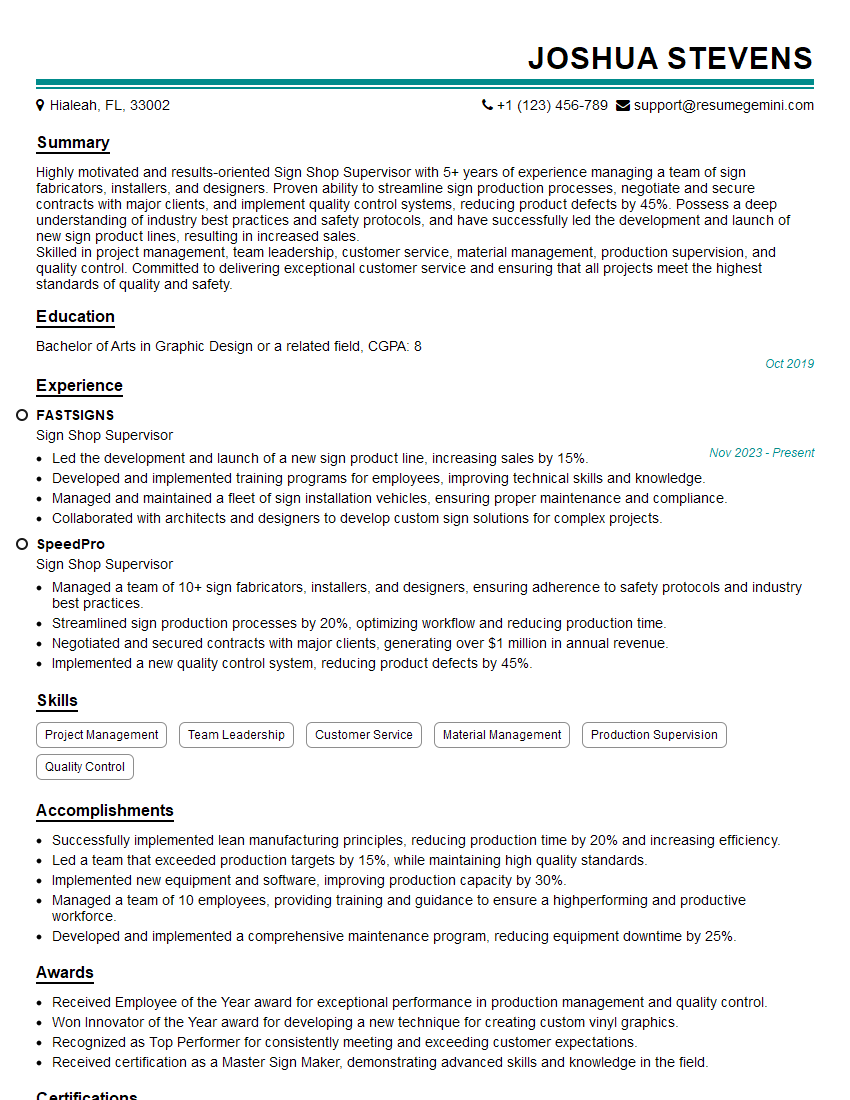

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sign Shop Supervisor

1. What are the different types of signs that a sign shop typically produces?

A sign shop can produce different types of signage that can cater to various purposes. Here are some of the most common ones:

- Banners: These are printed on flexible material and are used for indoor or outdoor advertising.

- Decals: These are pressure-sensitive label materials that can be applied to different surfaces, including vehicles, walls, and windows.

- Dimensional letters: These are three-dimensional letters or numbers that can be made of different materials like acrylic, metal, or foam.

- Lightboxes: These are illuminated signs that can be used both indoors and outdoors. They provide high visibility even at night or in low-light conditions.

- Neon signs: These are eye-catching signs that use electrified gas to create glowing displays. They are often used for advertising or decoration.

- Vehicle wraps: These are large printed graphics that are applied to vehicles. They can be used for advertising, branding, or decorative purposes.

2. What are the key elements to consider when designing an effective sign?

Legibility and Visibility:

- Use clear and concise fonts that are easy to read.

- Choose colors that contrast well and ensure visibility from a distance.

- Consider the placement and size of the sign for optimal visibility.

Message and Content:

- Craft a message that is concise, impactful, and relevant to the target audience.

- Ensure the sign conveys the intended message effectively.

Materials and Durability:

- Select materials that are durable and can withstand the intended environment.

- Consider factors such as weather conditions, UV resistance, and potential vandalism.

3. What are the different printing techniques used in sign making?

- Digital printing: This involves using a digital printer to print directly onto the sign material. It offers high-quality prints with vibrant colors and fine details.

- Screen printing: This technique uses a mesh screen to transfer ink onto the sign material. It is commonly used for large-scale production of simple designs and can produce durable prints.

- Vinyl printing: This involves printing onto vinyl material, which is then applied to the sign surface. It is a versatile technique suitable for both indoor and outdoor signage.

- Direct-to-substrate printing: This method involves printing directly onto the sign material, such as acrylic or metal, using specialized UV-curable inks. It provides high-quality prints with excellent durability.

4. What types of software do you use for sign design and production?

- Adobe Creative Suite: This includes software such as Illustrator, Photoshop, and InDesign, which are industry-standard tools for graphic design and layout.

- Sign-making software: Specialized software designed specifically for sign design and production, such as SignLab, FlexiSIGN, and CorelDRAW Graphics Suite.

- CAD software: For designing and creating dimensional signs and other complex structures, software like AutoCAD and SolidWorks may be used.

5. What are the key steps involved in project management for sign production?

- Project initiation: Define project scope, timeline, and budget.

- Design and approval: Create sign design based on client requirements and obtain approvals.

- Production planning: Determine materials, printing techniques, and production schedule.

- Production: Manufacture and assemble the sign according to the design specifications.

- Installation: Safely and securely install the sign at the designated location.

- Project completion: Finalize the project, evaluate outcomes, and follow up with the client.

6. How do you ensure quality control in the sign production process?

- Design review: Thoroughly checking designs for accuracy, clarity, and compliance with specifications.

- Material inspection: Inspecting incoming materials for defects or damage before use.

- Production monitoring: Supervising the production process to ensure adherence to standards and timelines.

- Quality assurance testing: Conducting tests to verify the durability, visibility, and functionality of the finished signs.

- Customer feedback: Gathering feedback from clients to continuously improve quality and meet their expectations.

7. What are the safety protocols that must be followed in a sign shop?

- Proper handling of equipment: Ensure proper training and follow safety guidelines for operating machinery and tools.

- Use of personal protective equipment: Wear appropriate safety gear, such as gloves, safety glasses, and respirators, when necessary.

- Safe handling of chemicals: Follow proper storage and disposal procedures for hazardous materials used in sign production.

- Electrical safety: Maintain electrical equipment regularly and follow lockout/tagout procedures.

- Emergency preparedness: Know emergency procedures and evacuation routes in case of accidents or fires.

8. How do you manage a team of sign makers and designers?

- Effective communication: Clearly communicate project requirements, goals, and timelines with the team.

- Skill assessment and delegation: Identify team members’ strengths and assign tasks accordingly to optimize productivity.

- Motivation and recognition: Create a positive work environment and recognize employees’ contributions to boost morale.

- Training and development: Provide opportunities for professional growth and skill enhancement for the team.

- Conflict resolution: Address any conflicts or disagreements within the team promptly and professionally.

9. What are the latest trends and innovations in the sign industry?

- Digital signage: Interactive and dynamic displays that can be updated remotely.

- LED and neon signs: Energy-efficient and visually striking lighting solutions.

- 3D printing for signs: Creating unique and complex sign designs.

- Environmental sustainability: Focus on using eco-friendly materials and reducing waste.

- Augmented reality (AR) and virtual reality (VR) integration: Interactive experiences that enhance customer engagement.

10. How do you stay up-to-date with advancements in sign-making technology and best practices?

- Industry conferences and trade shows: Attend events to learn about new products, technologies, and trends.

- Online resources and industry publications: Read trade magazines, blogs, and websites to stay informed.

- Networking with peers and experts: Connect with other sign professionals to exchange knowledge and ideas.

- Continuing education and workshops: Participate in training programs to enhance skills and stay updated.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sign Shop Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sign Shop Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sign Shop Supervisors play a crucial role in overseeing the production and installation of signs. They are responsible for leading a team of sign makers and ensuring that all projects are completed on time and within budget.

1. Manage Production

Supervisors are responsible for planning and scheduling work, assigning tasks to team members, and monitoring their progress.

- Coordinate with clients to determine project requirements

- Develop and implement production plans

2. Quality Control

They ensure that all signs meet the highest quality standards.

- Inspect signs for defects

- Ensure that signs are installed correctly

3. Customer Service

Supervisors are often the main point of contact for clients, so they must be able to communicate effectively and resolve any issues that may arise.

- Respond to customer inquiries

- Resolve customer complaints

4. Safety

Supervisors are responsible for ensuring that all employees follow safety procedures and that the work environment is safe.

- Conduct safety inspections

- Develop and implement safety procedures

Interview Tips

Preparing for an interview for a Sign Shop Supervisor position requires a combination of technical knowledge and soft skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, culture, and products/services. Learn about the specific responsibilities of the Sign Shop Supervisor role and how your skills and experience align with them.

- Visit the company’s website and social media pages.

- Read industry news and articles related to sign production.

2. Highlight Your Experience and Skills

Emphasize your relevant experience in sign production, including your proficiency in design, fabrication, and installation. Showcase your skills in project management, quality control, and customer service.

- Quantify your accomplishments with specific examples.

- Prepare examples of successful projects you have led.

3. Demonstrate Your Leadership and Communication Skills

Supervisors must be able to effectively lead and motivate a team. Highlight your leadership style, conflict resolution abilities, and communication skills.

- Describe a situation where you successfully resolved a conflict within your team.

- Provide examples of how you have effectively communicated with clients and stakeholders.

4. Be Prepared for Technical Questions

Interviewers may ask technical questions about sign production processes, materials, and equipment. Be prepared to discuss your knowledge and experience in these areas.

- Review common sign-making techniques and equipment.

- Research the latest industry trends and innovations.

5. Ask Thoughtful Questions

Asking thoughtful questions demonstrates your engagement and interest in the position. Prepare questions about the company’s growth plans, industry challenges, or specific projects related to the role.

- Ask about the company’s commitment to quality and customer satisfaction.

- Inquire about opportunities for professional development and advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sign Shop Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!