Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Toy Parts Former Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Toy Parts Former Supervisor so you can tailor your answers to impress potential employers.

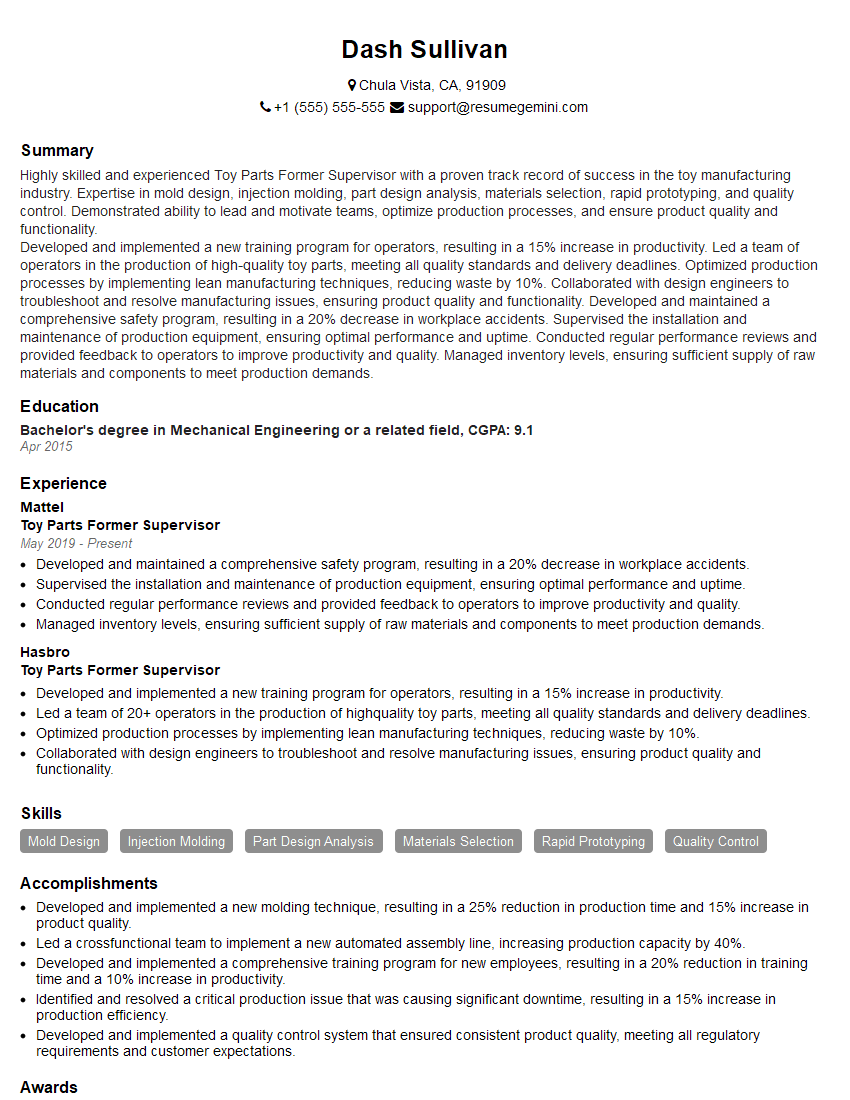

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Toy Parts Former Supervisor

1. What are the key performance indicators (KPIs) you track for the toy parts forming process? How do you use this data to improve operations?

Key Performance Indicators (KPIs) provide valuable insights into the efficiency and effectiveness of the toy parts forming process. The data is analyzed to identify areas for improvement and make informed decisions.

- Overall Equipment Effectiveness (OEE): Measures the percentage of time a machine is available, running, and producing good parts.

- Cycle Time: The time it takes to produce one part.

- Scrap Rate: The percentage of parts rejected due to defects.

- First Pass Yield: The percentage of parts that meet specifications without requiring rework.

2. Describe the quality control procedures you have implemented to ensure the accuracy and consistency of toy parts.

Process Control

- Statistical Process Control (SPC): Monitors and analyzes process variables to identify and eliminate sources of variation.

- Automated Inspection Equipment: Uses vision systems and sensors to inspect parts for defects.

Materials Control

- Supplier Qualification: Evaluates suppliers based on their quality and reliability.

- Incoming Material Inspection: Inspects incoming materials to ensure they meet specifications.

3. What is your approach to managing and motivating a team of operators in a toy parts forming facility?

Effective team management and motivation are crucial for maintaining a productive and engaged workforce.

- Communication: Clear and open communication is key to aligning team goals and addressing challenges.

- Training and Development: Providing ongoing training opportunities empowers operators and improves their skills.

- Recognition and Rewards: Acknowledging and rewarding team members’ efforts fosters motivation and loyalty.

- Empowerment: Giving operators a sense of ownership and responsibility increases their engagement.

4. How would you address a situation where machine downtime is impacting production targets?

Unexpected machine downtime can significantly hinder production. A proactive approach is essential to minimize its impact.

- Immediate Action: Isolate the issue, identify the root cause, and initiate repairs promptly.

- Preventive Maintenance: Implement a regular maintenance schedule to prevent breakdowns.

- Spare Parts Inventory: Maintain a readily available inventory of critical spare parts to expedite repairs.

- Cross-Training: Train operators to handle basic repairs, reducing reliance on external maintenance personnel.

5. Can you describe the process of developing and implementing new toy part designs into the production line?

Integrating new designs into the production process requires collaboration and effective planning.

- Design Review: Evaluate new designs for feasibility, manufacturability, and quality.

- Process Development: Determine the necessary tooling, materials, and production parameters.

- Pilot Production: Run trial production to refine the process and identify any issues.

- Full-Scale Implementation: Gradually scale up production after addressing any challenges encountered during pilot production.

6. How do you ensure that toy parts meet safety and regulatory standards?

Compliance with safety and regulatory standards is paramount to protect consumers.

- Material Composition: Verify that materials used meet industry safety regulations.

- Design Compliance: Ensure that toy parts adhere to ergonomic and safety guidelines.

- Testing and Certification: Conduct rigorous testing to meet international standards and obtain necessary certifications.

7. What are the common challenges you have faced in your role as Toy Parts Former Supervisor, and how have you overcome them?

Every role comes with its unique set of challenges. Sharing your experiences demonstrates resilience and problem-solving abilities.

- Production Delays: Identified bottlenecks and implemented efficiency measures to reduce downtime.

- Quality Issues: Established a quality control system and trained operators to maintain high standards.

- Employee Turnover: Implemented employee engagement programs and provided professional development opportunities to retain talent.

8. How do you stay up-to-date with the latest developments and technologies in the toy manufacturing industry?

Continuous learning is essential to remain competitive and innovative.

- Trade Shows and Conferences: Attend industry events to learn about new technologies and best practices.

- Technical Publications: Read industry journals and magazines to stay informed about advancements.

- Online Resources: Utilize online platforms and webinars to access knowledge and connect with experts.

9. What are your thoughts on automation and its potential impact on the toy parts forming process?

Automation is rapidly transforming industries. Discuss the potential benefits and challenges.

- Increased Efficiency: Automation can improve production speeds and reduce cycle times.

- Improved Quality: Automated processes reduce human error, leading to higher quality parts.

- Reduced Labor Costs: Automation can lower labor costs by eliminating repetitive tasks.

10. How would you handle a situation where production targets are not being met and there is pressure from management to increase output?

Balancing production demands with quality is crucial. Describe your approach to this scenario.

- Analyze the Situation: Identify the root causes for not meeting targets, such as machine issues, material shortages, or training gaps.

- Prioritize Tasks: Determine which tasks are most critical and focus on completing those first.

- Communicate with Management: Explain the situation and provide realistic timelines for improvement.

- Implement Process Improvements: Identify areas where efficiency can be enhanced and implement solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Toy Parts Former Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Toy Parts Former Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Toy Parts Former Supervisor holds a position of great responsibility within the organization, overseeing the production of high-quality toy components. Their day-to-day tasks encompass a wide range of duties, including:

1. Production Management

The supervisor ensures the efficient operation of the production line, monitoring and adjusting processes to meet production targets. They develop and implement strategies to optimize productivity and minimize waste, while maintaining strict adherence to safety regulations.

- Plan and schedule production processes, ensuring timely completion and adherence to deadlines.

- Monitor production lines to identify bottlenecks and implement solutions for smooth operation.

2. Quality Control

The supervisor ensures the production of high-quality toy parts. They set quality standards and conduct regular inspections to ensure compliance. They identify and address any deviations from specifications, implementing corrective actions as needed.

- Establish and enforce quality control procedures to ensure parts meet industry standards.

- Identify and resolve quality issues, ensuring timely resolution and minimizing defects.

3. Team Management

The supervisor leads a team of production operators, providing guidance, support, and training. They motivate and encourage their team, creating a positive and productive work environment.

- Supervise and train production operators, providing clear instructions and technical guidance.

- Foster a positive and collaborative team environment, promoting teamwork and accountability.

4. Communication and Coordination

The supervisor effectively communicates with various departments within the organization, including production, engineering, and quality control. They coordinate with suppliers and external vendors to ensure the smooth flow of materials and components.

- Communicate effectively with team members, peers, and management to ensure clear understanding and alignment.

- Coordinate with suppliers and vendors to ensure timely delivery of materials and parts.

Interview Tips

To ace the interview for a Toy Parts Former Supervisor position, candidates should be well-prepared and demonstrate a clear understanding of the job requirements and the industry. Here are some tips and hacks to help candidates succeed:

1. Preparation

Thoroughly research the company and the toy manufacturing industry. Gather information about the company’s products, production processes, and market position. This knowledge will help you demonstrate your understanding of their business and align your answers with their needs.

- Study the job description and identify the key responsibilities and qualifications.

- Prepare examples from your previous experience that showcase your skills and accomplishments.

2. Highlight Your Skills

Emphasize your ability to manage production processes efficiently, ensuring high quality and meeting deadlines. Showcase your experience in implementing quality control measures, resolving issues, and driving continuous improvement.

- Provide specific examples of how you have improved production efficiency or reduced defects.

- Highlight your ability to motivate and lead a team, fostering a positive and productive work environment.

3. Industry Knowledge

Demonstrate your knowledge of toy manufacturing techniques, materials, and safety regulations. Discuss industry trends and how they impact production processes. This will show the interviewer that you are up-to-date and passionate about the industry.

- Be familiar with different types of toy materials and their properties.

- Stay updated on industry standards and regulations to ensure compliance.

4. Communication and Confidence

Throughout the interview, maintain clear and concise communication. Express your ideas confidently and provide specific examples to support your statements. Be enthusiastic about the opportunity and demonstrate your commitment to delivering results.

- Practice your answers to common interview questions to build confidence and fluency.

- Ask thoughtful questions at the end of the interview to show your engagement and interest in the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Toy Parts Former Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!