Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Type Disk Quality Control Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

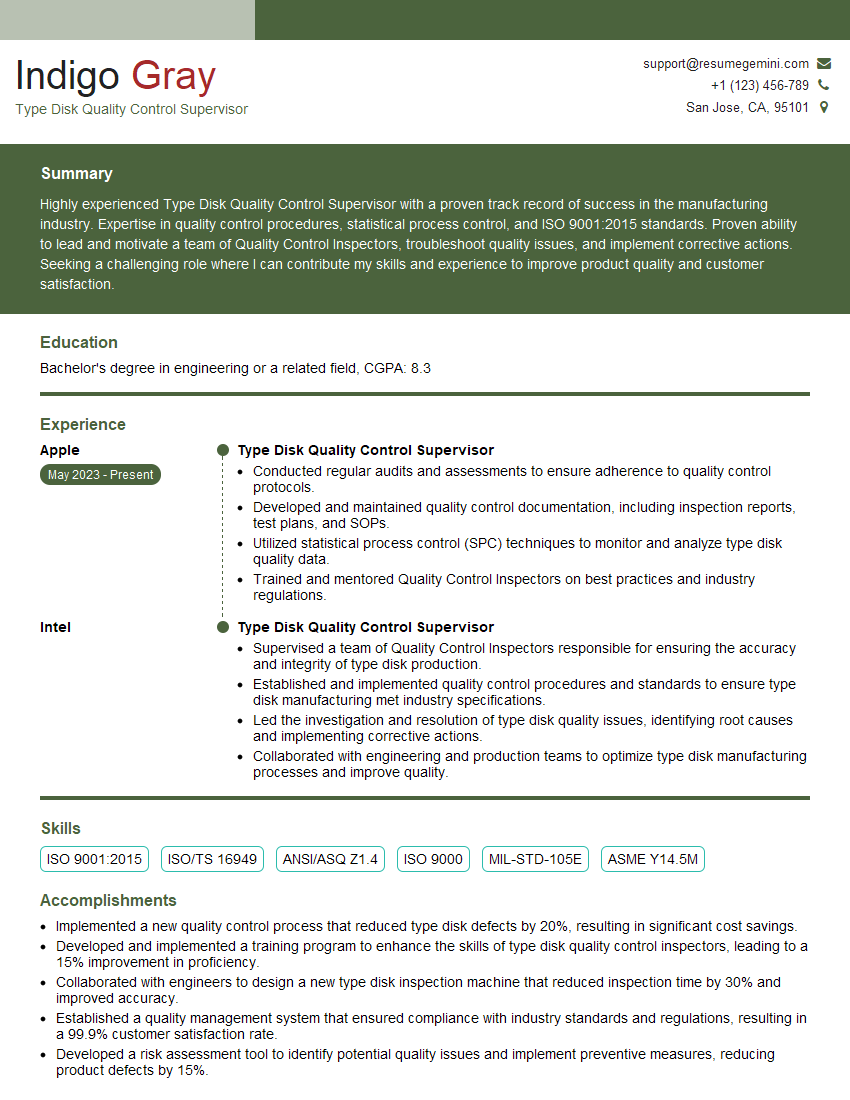

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Type Disk Quality Control Supervisor

1. Can you explain the core responsibilities of a Type Disk Quality Control Supervisor?

As a Type Disk Quality Control Supervisor, my primary responsibilities would include:

- Ensuring the quality of all manufactured type disks meets or exceeds industry standards.

- Implementing and maintaining quality control processes to prevent defects and ensure product performance.

- Inspecting type disks at various stages of production to identify and resolve any quality issues.

- Analyzing quality data to identify trends and areas for improvement in production processes.

- Training and supervising quality control staff to ensure consistency and accuracy in quality control procedures.

- Collaborating with production and design teams to enhance product quality and resolve quality concerns.

- Staying up-to-date with industry best practices and technological advancements in quality control.

2. What methods do you use to inspect and test the quality of type disks?

Non-Destructive Testing:

- Visual Inspection: Examining type disks for surface defects, scratches, or other physical imperfections.

- Dimensional Measurement: Using precision measuring tools to verify the dimensions and tolerances of type disks.

- Magnetic Inspection: Utilizing magnetic particle or flux leakage testing to detect surface or subsurface defects.

- Ultrasonic Inspection: Applying ultrasonic waves to detect internal flaws, such as cracks or voids.

- X-Ray Inspection: Subjecting type disks to X-ray radiation to reveal internal defects or foreign objects.

Destructive Testing:

- Bend Testing: Applying force to type disks to assess their flexibility and resistance to bending.

- Fatigue Testing: Repeatedly loading and unloading type disks to simulate real-world operating conditions and evaluate their durability.

- Endurance Testing: Running type disks at elevated temperatures and speeds to assess their long-term performance.

3. How do you manage the production process to ensure the consistent quality of type disks?

To ensure consistent quality, I would implement the following measures:

- Establish clear quality standards and specifications.

- Train and certify operators on quality control procedures.

- Implement statistical process control (SPC) techniques to monitor and analyze production processes.

- Utilize automated inspection equipment to minimize human error.

- Conduct regular audits and reviews to identify and address potential quality issues.

- Foster a culture of continuous improvement by encouraging feedback and suggestions from operators.

4. Describe the quality control documentation that you maintain as a Type Disk Quality Control Supervisor.

As a Quality Control Supervisor, I would maintain the following documentation:

- Inspection reports detailing the results of quality inspections.

- Calibration records for all inspection equipment.

- SPC charts to track process performance and identify trends.

- Non-conformance reports to document any deviations from quality standards.

- Corrective and preventive action (CAPA) records to track the resolution and prevention of quality issues.

- Quality manuals and procedures outlining quality control processes and policies.

5. How do you stay up-to-date with the latest quality control technologies and industry best practices?

To stay current, I would:

- Attend industry conferences and seminars.

- Read technical journals and research papers.

- Participate in professional organizations, such as the American Society for Quality (ASQ).

- Network with other quality control professionals.

- Explore new technologies and their potential applications in quality control.

6. What are the challenges you have faced as a Type Disk Quality Control Supervisor, and how did you overcome them?

One challenge I encountered was addressing customer complaints about type disk failures. To overcome this, I conducted a thorough investigation, analyzed the failure data, and identified the root cause. I then implemented corrective actions to improve the manufacturing process and reduce the risk of future failures.

7. How do you prioritize your workload and manage multiple projects simultaneously?

To prioritize my workload, I use the following techniques:

- Establish clear priorities based on deadlines and importance.

- Break down large projects into smaller tasks and set achievable milestones.

- Delegate tasks to team members based on their skills and availability.

- Use project management tools to track progress and identify potential bottlenecks.

8. How do you measure the effectiveness of your quality control processes?

I measure the effectiveness of quality control processes through the following metrics:

- Percentage of products meeting quality standards.

- Customer satisfaction ratings.

- Number of non-conformance reports.

- Cost of quality (e.g., rework, scrap, warranty claims).

- Improvements in production efficiency and yield.

9. What are the key quality control challenges facing the type disk industry today?

The type disk industry is facing several key quality control challenges, including:

- Increasing demand for higher-density and higher-performance type disks.

- Miniaturization of type disks, leading to tighter tolerances and reduced inspection margins.

- Integration of new materials and technologies, requiring specialized testing and inspection techniques.

- Growing customer expectations for reliability and durability.

10. How do you see the role of Type Disk Quality Control Supervisors evolving in the future?

The role of Type Disk Quality Control Supervisors is evolving to include:

- Greater emphasis on data analysis and process optimization.

- Increased collaboration with design and manufacturing teams.

- Adoption of new technologies, such as AI and machine learning, for quality control.

- A focus on sustainability and environmental compliance.

- Continued development of quality management systems and standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Type Disk Quality Control Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Type Disk Quality Control Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Type Disk Quality Control Supervisor is a vital role within the manufacturing process, ensuring the quality and reliability of disk drives. The responsibilities are diverse and include:

1. Inspecting and Testing Disk Drives

Regularly inspecting and testing disk drives using specialized equipment to identify defects and ensure compliance with specifications.

2. Analyzing and Troubleshooting Issues

Analyzing and troubleshooting any defects or quality issues identified during testing, determining root causes, and implementing corrective actions.

3. Monitoring Quality Metrics

Continuously monitoring quality metrics and identifying areas for improvement, implementing initiatives to enhance the quality and reliability of disk drives.

4. Managing and Training Team

Managing and training a team of quality control technicians, providing guidance and support to ensure consistent and effective quality control procedures.

5. Collaborating with Other Departments

Collaborating with engineering, production, and supply chain teams to identify and resolve quality issues, and improve overall manufacturing processes.

6. Maintaining Compliance and Regulations

Ensuring compliance with industry standards, regulations, and customer requirements related to disk drive quality and performance.

Interview Tips

To ace the interview for a Type Disk Quality Control Supervisor role, it is essential to prepare thoroughly and demonstrate your skills and experience. Here are some interview tips to help you succeed:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. Researching the company’s website and news articles will provide valuable insights and help you connect with the interviewer on a deeper level.

2. Practice Your Technical Skills

Expect technical questions related to disk drive manufacturing and quality control. Practice answering questions about testing procedures, defect analysis, and quality improvement methodologies. Demonstrate your knowledge of industry standards and best practices.

3. Highlight Your Problem-Solving Skills

In an interview, you will likely be asked to describe how you approach and solve problems. Provide specific examples from your past experience where you identified and resolved complex quality issues. Emphasize your analytical and troubleshooting abilities.

4. Showcase Your Leadership and Team Management Skills

As a supervisor, you need to demonstrate your ability to lead and manage a team effectively. Describe your experiences in motivating and training team members, setting clear expectations, and fostering a collaborative work environment.

5. Prepare for Behavioral Interview Questions

Behavioral interview questions focus on your past experiences and behaviors. Research common behavioral interview questions and prepare examples that demonstrate your skills and qualities relevant to the role, such as attention to detail, communication, and adaptability.

6. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic demeanor. Dress professionally, arrive on time, and actively engage with the interviewer. Show your passion for quality control and your interest in the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Type Disk Quality Control Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.