Are you gearing up for a career in Wet End Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wet End Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

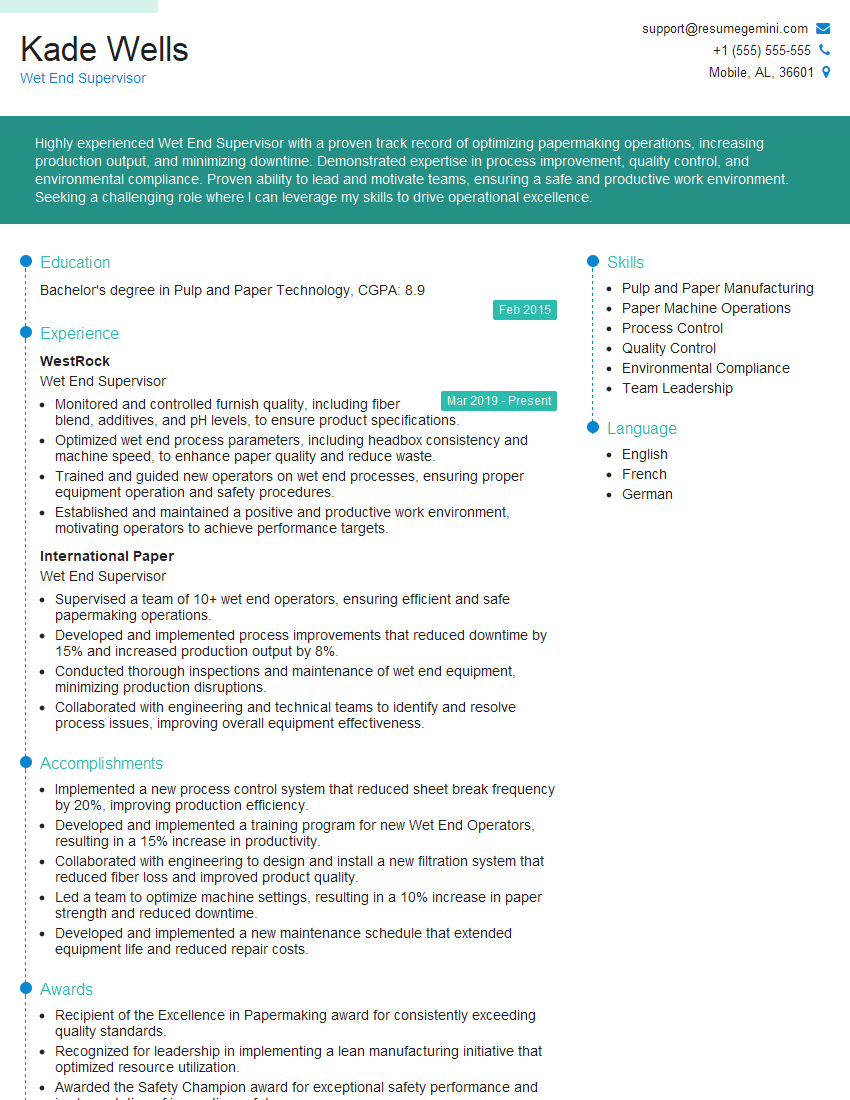

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wet End Supervisor

1. What are the key responsibilities of a Wet End Supervisor in a paper mill?

As a Wet End Supervisor, my primary responsibilities include:

- Overseeing all aspects of the wet end operations, including stock preparation, headbox management, and wire section

- Monitoring and controlling paper machine parameters to ensure optimal production efficiency and quality

- Performing daily equipment inspections and troubleshooting any issues to minimize downtime

- Training and supervising a team of operators to maintain a safe and efficient work environment

2. What techniques do you use to optimize paper machine efficiency and minimize breaks?

To optimize efficiency and minimize breaks, I utilize various techniques:

Parameter Monitoring

- Continuously monitoring key parameters such as pulp consistency, headbox consistency, and machine speed

- Identifying and adjusting parameters to maintain optimal conditions for stable paper production

Equipment Maintenance

- Implementing a regular maintenance schedule for all wet end equipment

- Identifying potential issues early on through proactive maintenance to prevent unplanned breakdowns

Operator Training

- Providing comprehensive training to operators on proper machine operation and troubleshooting procedures

- Emphasizing the importance of teamwork and communication to minimize communication errors

3. How do you handle quality control issues on the wet end?

Quality control is crucial in the wet end:

- Regularly monitoring paper quality parameters such as basis weight, moisture content, and tensile strength

- Identifying and analyzing deviations from specifications to determine root causes

- Implementing corrective actions based on data analysis and process knowledge to improve quality

4. What steps do you take to ensure a safe and efficient work environment?

Safety is paramount in the wet end:

- Conducting regular safety inspections and risk assessments to identify potential hazards

- Enforcing safety protocols, including proper use of personal protective equipment and lockout/tagout procedures

- Training operators on emergency response measures and providing them with the necessary resources

5. What is your experience with managing a team of operators?

Effective team management is essential:

- Providing clear instructions and delegating tasks to team members based on their skills and experience

- Creating a positive and motivating work environment where operators feel valued and engaged

- Recognizing and rewarding exceptional performance to foster a culture of excellence

6. How do you stay updated on the latest advancements in papermaking technology?

Keeping up with advancements is crucial:

- Attending industry conferences and workshops to learn about new technologies and best practices

- Reading technical publications and research papers to stay abreast of innovations

- Collaborating with vendors and consultants to explore and implement new solutions

7. What is your approach to continuous improvement in the wet end?

Continuous improvement is a key driver:

- Regularly collecting and analyzing data to identify areas for improvement

- Developing and implementing process optimizations to increase efficiency and reduce waste

- Involving operators in the improvement process to gather their insights and support

8. What is your experience with process control systems in the wet end?

Process control systems play a critical role:

- Proficient in operating and troubleshooting process control systems used in the wet end

- Understanding of PID control loops and their application in paper machine control

- Experience in data analysis and process optimization using process control systems

9. How do you handle shift work and manage the challenges of working in a 24/7 environment?

Shift work requires adaptability and resilience:

- Maintaining a consistent sleep schedule and healthy lifestyle to cope with fluctuating work hours

- Effective communication and coordination with other shifts to ensure seamless operations

- Adapting to the unique challenges of working in a 24/7 environment, including fatigue management and maintaining focus

10. What is your understanding of the environmental regulations related to papermaking operations?

Environmental compliance is essential:

- Awareness of the relevant environmental regulations and standards applicable to papermaking

- Implementation of measures to minimize the environmental impact of wet end operations

- Monitoring and reporting on environmental performance to ensure compliance and reduce the risk of penalties

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wet End Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wet End Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Wet End Supervisor plays a critical role in ensuring the smooth and efficient operation of the wet end papermaking process. Their responsibilities encompass a wide range of tasks, including:

1. Production Management

Oversees all aspects of paper production in the wet end, from pulp preparation to sheet formation. Ensures that production targets are met and quality standards are maintained.

2. Equipment Maintenance and Operation

Responsible for the proper operation, maintenance, and repair of all wet end equipment, including pulpers, screens, headboxes, and forming wires. Implements preventive maintenance programs and troubleshooting procedures.

3. Quality Control

Monitors the quality of incoming pulp and finished paper products. Conducts regular inspections and tests to ensure that paper meets specifications. Identifies and resolves quality issues promptly.

4. Process Optimization

Continuously seeks ways to improve the efficiency and effectiveness of the wet end process. Evaluates new technologies and process modifications. Implements process improvements to reduce waste, downtime, and energy consumption.

5. Safety and Environmental Compliance

Ensures compliance with all safety regulations and environmental standards. Conducts safety training and hazard assessments. Monitors environmental performance and implements measures to reduce pollution.

6. Team Leadership and Management

Supervises and motivates a team of wet end operators. Provides training, mentorship, and performance feedback. Ensures a positive and productive work environment.

Interview Tips

Preparing for a Wet End Supervisor interview requires a combination of technical knowledge, preparation, and effective communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Thoroughly research the company’s history, products, and mission statement. Understand the industry’s current trends and challenges. This knowledge will help you demonstrate your interest in the company and the role.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses. Practice your answers out loud to improve your delivery and confidence. Focus on highlighting your skills, experience, and qualifications that are most relevant to the job.

3. Quantify Your Accomplishments

When describing your past experiences, use specific numbers and metrics to quantify your accomplishments. Avoid vague or general statements. For example, instead of saying “I improved production efficiency,” say “I implemented a process improvement that increased production efficiency by 15%.”

4. Be Prepared to Discuss Safety

Safety is a top priority in papermaking operations. Be prepared to discuss your safety knowledge and experience. Highlight your commitment to ensuring a safe and healthy work environment.

5. Demonstrate Your Leadership Skills

Emphasize your ability to lead and motivate a team. Provide examples of situations where you have successfully managed a team to achieve goals.

6. Dress Professionally

First impressions matter. Dress professionally for the interview, even if it is a virtual interview. This shows respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wet End Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!