Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Aircraft Line Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

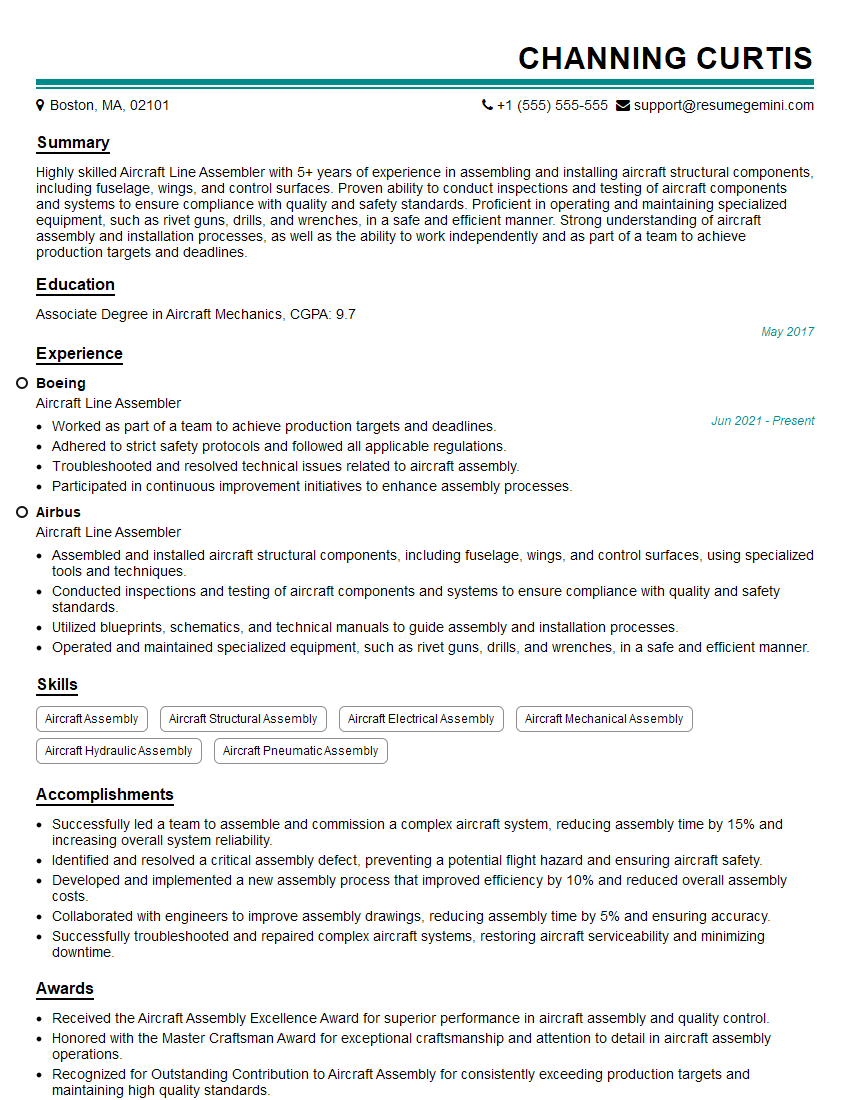

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Line Assembler

1. Describe the steps involved in assembling an aircraft fuselage?

The steps involved in assembling an aircraft fuselage are as follows:

- Inspect the fuselage components to ensure they meet specifications.

- Assemble the fuselage sections using bolts, rivets, and adhesives.

- Install the electrical wiring, hydraulic lines, and other systems.

- Inspect the fuselage assembly to ensure it meets specifications.

- Prepare the fuselage for painting and other finishing processes.

2. What are the different types of materials used in aircraft fuselage construction?

The different types of materials used in aircraft fuselage construction include:

Metals

- Aluminum alloys

- Titanium alloys

- Steel alloys

Composites

- Carbon fiber reinforced polymers (CFRPs)

- Glass fiber reinforced polymers (GFRPs)

- Kevlar reinforced polymers (KRPs)

3. What are the different types of tools and equipment used in aircraft fuselage assembly?

The different types of tools and equipment used in aircraft fuselage assembly include:

- Riveting guns

- Drilling machines

- Cutting tools

- Measuring tools

- Inspection equipment

4. What are the safety precautions that must be followed when working on aircraft fuselages?

The safety precautions that must be followed when working on aircraft fuselages include:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a hard hat.

- Follow all safety procedures and guidelines.

- Be aware of the hazards associated with working on aircraft fuselages, such as electrical hazards, chemical hazards, and fall hazards.

- Take breaks as needed to avoid fatigue.

- Report any unsafe conditions or practices to a supervisor.

5. What are the quality control procedures that are used to ensure the quality of aircraft fuselages?

The quality control procedures that are used to ensure the quality of aircraft fuselages include:

- Inspecting the fuselage components to ensure they meet specifications.

- Inspecting the fuselage assembly to ensure it meets specifications.

- Testing the fuselage to ensure it meets performance requirements.

- Documenting all quality control activities.

6. What are the different types of aircraft fuselage designs?

The different types of aircraft fuselage designs include:

Moncoque

- The fuselage is a single, thin shell.

- The skin of the fuselage carries the loads.

Semi-monocoque

- The fuselage is a combination of a thin shell and a framework of beams and ribs.

- The skin of the fuselage and the framework share the loads.

Truss

- The fuselage is a framework of beams and ribs.

- The skin of the fuselage is attached to the framework.

7. What are the different types of aircraft fuselage cross-sections?

The different types of aircraft fuselage cross-sections include:

Circular

- The fuselage is a circle.

- This design is common on small aircraft.

Oval

- The fuselage is an oval.

- This design is common on medium-sized aircraft.

Rectangular

- The fuselage is a rectangle.

- This design is common on large aircraft.

8. What are the different types of aircraft fuselage configurations?

The different types of aircraft fuselage configurations include:

Single-aisle

- The fuselage has a single aisle running down the center.

- This design is common on small and medium-sized aircraft.

Twin-aisle

- The fuselage has two aisles running down the center.

- This design is common on large aircraft.

Wide-body

- The fuselage is very wide.

- This design is common on large aircraft.

9. What are the different types of aircraft fuselage materials?

The different types of aircraft fuselage materials include:

Aluminum alloys

- Aluminum alloys are lightweight and strong.

- They are commonly used in the construction of small and medium-sized aircraft.

Titanium alloys

- Titanium alloys are lightweight and strong.

- They are commonly used in the construction of military aircraft and high-performance aircraft.

Composite materials

- Composite materials are made of a combination of materials, such as carbon fiber and epoxy resin.

- They are lightweight and strong.

- They are increasingly being used in the construction of aircraft fuselages.

10. What are the different types of aircraft fuselage structures?

The different types of aircraft fuselage structures include:

Monocoque

- The fuselage is a single, thin shell.

- The skin of the fuselage carries the loads.

Semi-monocoque

- The fuselage is a combination of a thin shell and a framework of beams and ribs.

- The skin of the fuselage and the framework share the loads.

Truss

- The fuselage is a framework of beams and ribs.

- The skin of the fuselage is attached to the framework.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Line Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Line Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Assembly and Installation

- Assembles and installs aircraft components, such as wings, fuselage, engines, and landing gear, according to blueprints and specifications.

- Uses a variety of tools and equipment, such as power tools, hand tools, and cranes, to perform assembly tasks.

2. Inspection and Quality Control

- Inspects assembled components and systems to ensure they meet quality standards.

- Identifies and reports any defects or discrepancies to supervisors.

- Participates in quality control programs to improve assembly processes.

3. Maintenance and Repair

- Performs scheduled and unscheduled maintenance on aircraft, including repairs and replacements.

- Troubleshoots and diagnoses problems with aircraft systems and components.

- Follows maintenance manuals and procedures to ensure proper repairs and maintenance.

4. Safety and Compliance

- Adheres to safety regulations and procedures established by the Federal Aviation Administration (FAA) and other regulatory agencies.

- Uses personal protective equipment (PPE) and follows proper safety protocols.

- Reports any unsafe conditions or practices to supervisors.

Interview Tips

1. Research the Company and the Position

- Visit the company’s website to learn about their history, products, and services.

- Identify the specific job requirements and responsibilities, and tailor your resume and cover letter accordingly.

2. Practice Your Answers to Common Interview Questions

- Prepare answers to questions about your skills, experience, and why you’re interested in the position.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

3. Dress Professionally and Arrive on Time

- First impressions matter, so dress appropriately in business attire.

- Plan your route and arrive at the interview location on time, or even slightly early.

4. Be Confident and Enthusiastic

- Project a positive attitude and demonstrate your passion for the aviation industry.

- Show the interviewer that you’re eager to learn and contribute to the team.

5. Ask Thoughtful Questions

- Asking questions shows that you’re engaged and interested in the position.

- Prepare a few specific questions about the company, the team, and the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aircraft Line Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!