Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Aircraft Structures and Surfaces Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Aircraft Structures and Surfaces Assembler so you can tailor your answers to impress potential employers.

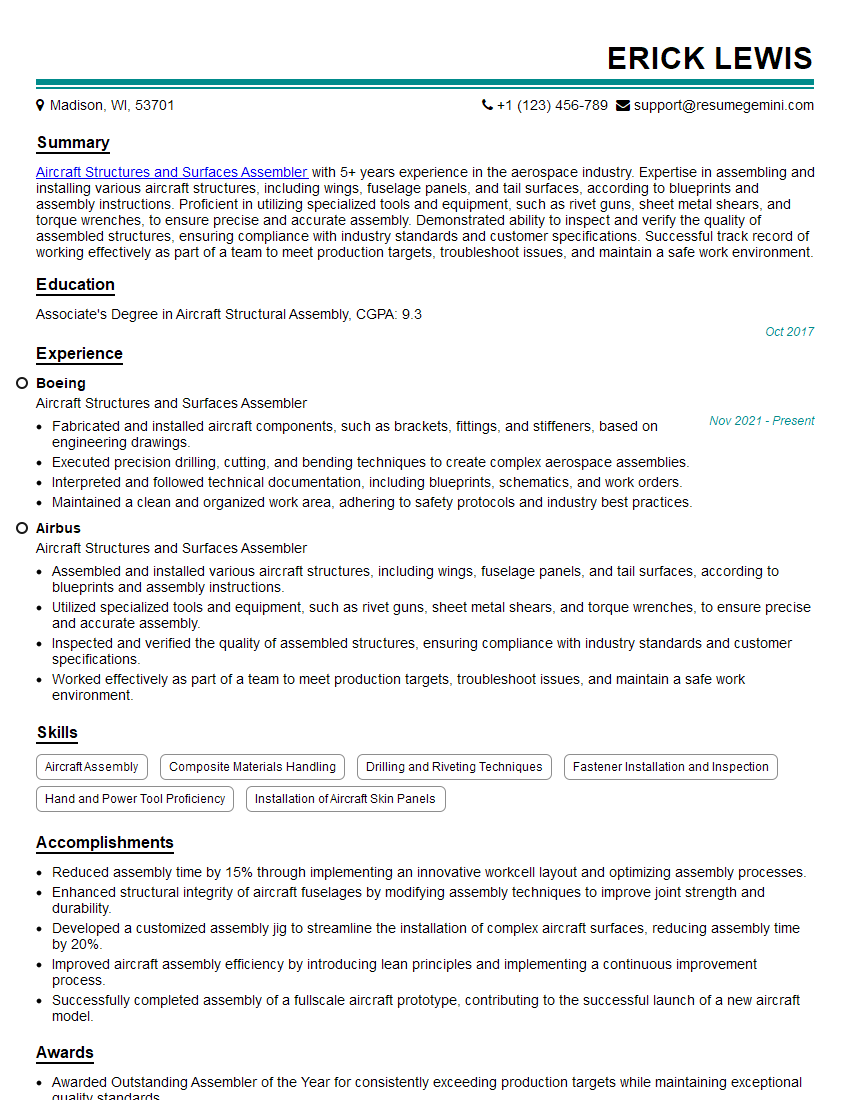

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Structures and Surfaces Assembler

1. Describe the process of assembling aircraft panels?

The process of assembling aircraft panels involves several key steps:

- Material Preparation: Inspect and ensure the panels meet specifications and are free of defects.

- Panel Assembly: Join panels together using mechanical fasteners, adhesives, or welding techniques.

- Deburring and Surface Preparation: Remove burrs and irregularities to prepare the surface for further processing.

- Riveting: Install rivets to permanently secure the panels and add strength.

- Inspection: Conduct thorough inspections to verify panel alignment, fastener tightness, and overall quality.

2. What are the common materials used in aircraft structures and surfaces?

- Aluminum alloys: Provide a high strength-to-weight ratio, making them ideal for aircraft structures.

- Titanium alloys: Offer high durability, strength, and resistance to heat and corrosion.

- Composite materials: Feature a combination of materials, such as carbon fiber and resins, providing exceptional strength and lightness.

- Steel: Used in high-load areas such as landing gear and engine mounts due to its superior strength.

3. What specific tools and equipment are used in aircraft assembly?

- Pneumatic wrenches: Tighten bolts and nuts securely.

- Riveting guns: Install and set rivets for joining panels.

- Countersink tools: Create recessed areas for flush-mounted fasteners.

- Inspection tools: Including micrometers, calipers, and feeler gauges to verify measurements and alignment.

- Specialized lifting equipment: Safely handle and position large aircraft panels during assembly.

4. How do you ensure the structural integrity of assembled components?

Ensuring structural integrity involves:

- Adhering to design specifications: Following detailed design drawings and engineering guidelines.

- Proper material handling: Using appropriate techniques to minimize damage or degradation of materials.

- Precise assembly techniques: Employing correct fastening methods, torque values, and adhesive application.

- Non-destructive testing: Conducting inspections using techniques such as ultrasonic testing or radiography to detect any defects or anomalies.

- Quality control processes: Implementing regular inspections and audits to maintain assembly standards and identify any potential areas of improvement.

5. What are the safety precautions to consider when working with aircraft structures?

- Wear proper protective gear: Use safety glasses, gloves, and appropriate clothing to protect against potential hazards.

- Handle materials cautiously: Avoid sharp edges, heavy loads, and awkward movements to prevent injury.

- Secure work areas: Keep work areas well-lit, clean, and free of trip hazards or obstructions.

- Follow designated procedures: Adhere to established safety protocols and clear any doubts with supervisors.

- Report hazards and incidents: Communicate any observed risks or accidents promptly to ensure prompt resolution and prevent future incidents.

6. What is the role of surface treatment in aircraft assembly?

Surface treatment is crucial for:

- Corrosion protection: Applying coatings or paints to prevent oxidation and enhance durability.

- Enhancing adhesive bonding: Preparing surfaces to maximize the strength and effectiveness of adhesive joints.

- Improving electrical conductivity: Ensuring electrical connections are secure and reliable.

- Reducing friction and wear: Applying lubricants or coatings to minimize wear and tear during assembly and operation.

- Providing aesthetic appeal: Maintaining the desired appearance and finish of aircraft surfaces.

7. What are the different types of fasteners used in aircraft assembly?

- Rivets: Permanent fasteners that create a strong and durable joint.

- Bolts and nuts: Allow for disassembly and reassembly when necessary.

- Screws: Similar to bolts, but with a threaded shank that screws into a prepared hole.

- Adhesives: Used to bond components together, providing strength and sealing properties.

- Pins: Used to align and secure components without permanent attachment.

8. How do you interpret and follow technical drawings and specifications for assembly?

Interpreting and following technical drawings and specifications involve:

- Understanding symbols and conventions: Familiar with the industry-standard symbols and notations used on drawings.

- Reading and analyzing drawings: Identifying dimensions, tolerances, materials, and assembly instructions.

- Verifying measurements: Using precision measuring tools to ensure components meet specified dimensions.

- Following assembly instructions: Step-by-step guidelines for assembling components correctly.

- Referencing engineering data: Consulting with design engineers or referring to technical manuals for clarifications and additional information.

9. Describe the process of quality control and inspection in aircraft assembly.

Quality control and inspection in aircraft assembly consist of:

- Regular inspections: Checking assemblies at various stages to ensure adherence to specifications.

- Non-destructive testing: Employing techniques such as ultrasonic or radiographic testing to detect hidden defects.

- Dimensional verification: Using precision measuring tools to confirm that components and assemblies meet specified tolerances.

- Functional testing: Conducting tests to verify the functionality and performance of assembled components.

- Documentation: Recording inspection results, identifying any non-conformances, and initiating corrective actions when necessary.

10. How do you stay updated with the latest advancements in aircraft structures and assembly techniques?

- Attend industry conferences and workshops: Network with experts and learn about emerging technologies.

- Read technical publications and journals: Stay informed about research and advancements in the field.

- Participate in training and certification programs: Enhance skills and knowledge through specialized training courses.

- Engage in discussions with colleagues: Share knowledge and stay abreast of best practices within the team.

- Monitor industry news and developments: Follow industry publications, attend webinars, and connect with professionals online to stay up-to-date.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Structures and Surfaces Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Structures and Surfaces Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Structures and Surfaces Assemblers are responsible for assembling, installing, and repairing aircraft structures and surfaces. They work with a variety of materials, including metal, composite, and plastic.

1. Assemble and install aircraft structures and surfaces

Aircraft Structures and Surfaces Assemblers assemble and install a variety of aircraft structures and surfaces, including wings, fuselage, and control surfaces.

- Follow blueprints and other technical documentation to assemble and install aircraft structures and surfaces

- Use hand tools and power tools to cut, drill, and fasten materials

- Inspect assembled structures and surfaces to ensure they meet specifications

2. Repair aircraft structures and surfaces

Aircraft Structures and Surfaces Assemblers repair damaged aircraft structures and surfaces. They may also perform preventive maintenance on aircraft to prevent future damage.

- Inspect aircraft structures and surfaces for damage

- Repair damaged structures and surfaces using a variety of techniques

- Perform preventive maintenance on aircraft to prevent future damage

3. Work with a variety of materials

Aircraft Structures and Surfaces Assemblers work with a variety of materials, including metal, composite, and plastic.

- Understand the properties of different materials

- Use appropriate tools and techniques to work with different materials

- Ensure that materials are used in accordance with specifications

4. Follow safety procedures

Aircraft Structures and Surfaces Assemblers must follow all safety procedures when working on aircraft.

- Wear appropriate safety gear

- Use tools and equipment safely

- Follow all safety procedures when working on aircraft

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Before you go on an interview, it’s important to do your research. This will help you understand the company’s culture and the specific requirements of the position.

- Read the company’s website and social media pages

- Talk to people who work at the company

- Read industry news and articles

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked. It’s a good idea to practice your answers to these questions in advance.

- Tell me about yourself

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview.

- Wear clean, pressed clothes

- Arrive 10-15 minutes early for your interview

4. Be confident and enthusiastic

Confidence is key in an interview. Be positive and enthusiastic about your skills and experience.

- Make eye contact with the interviewer

- Speak clearly and confidently

- Smile and be friendly

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Aircraft Structures and Surfaces Assembler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.