Are you gearing up for an interview for a Harness Installer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Harness Installer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

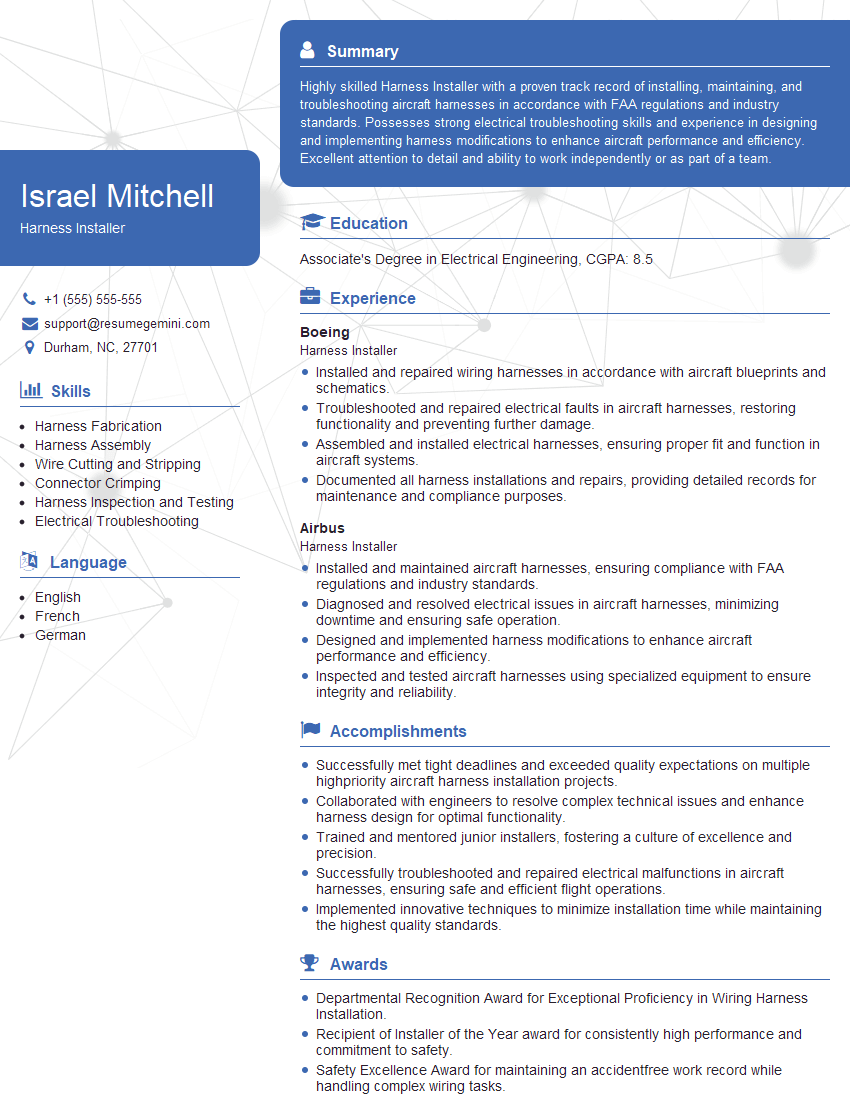

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Harness Installer

1. What are the different types of harnesses used in electrical installations?

Types of Harnesses

- Branch Harnesses

- Control Harnesses

- Power Harnesses

- Signal Harnesses

Purpose of Each Type

- Branch Harnesses: Transmit power to individual loads

- Control Harnesses: Carry low-current signals for control systems

- Power Harnesses: Handle high-current loads like motors and transformers

- Signal Harnesses: Transmit data and communication signals

2. How do you plan and prepare for a harness installation project?

- Review project specifications and drawings

- Identify materials, tools, and equipment required

- Determine labor requirements and schedule

- Plan for site preparation and safety measures

- Coordinate with other trades involved in the project

3. Describe the process of installing and securing a harness assembly.

- Identify and locate the mounting points

- Install any necessary supports or brackets

- Route the harness assembly and secure it with appropriate fasteners

- Connect the harness to terminal blocks and other electrical components

4. What are the key safety considerations when working with electrical harnesses?

- Wear appropriate personal protective equipment (PPE) including gloves, safety glasses, and earplugs

- Identify and avoid potential electrical hazards

- Use insulated tools and ensure proper grounding

- Follow lockout/tagout procedures to prevent accidental energization

- Have a clear understanding of electrical codes and regulations

5. How do you troubleshoot and repair harness assemblies?

- Inspect the harness for visible damage or loose connections

- Use a multimeter to test continuity and insulation resistance

- Repair any damaged wires or connectors using appropriate techniques

- Retrace wire paths to identify and correct any misrouting issues

- Update project documentation to reflect any repairs made

6. Describe the different types of materials used in harness assemblies and their applications.

Conductor Materials

- Copper: Excellent electrical conductivity, flexibility, and durability

- Aluminum: Lightweight and cost-effective, but less conductive than copper

- Silver: Highly conductive but expensive, used for specialized applications

Insulation Materials

- PVC: Widely used for its flexibility, fire resistance, and low cost

- Teflon: High-temperature resistance and chemical inertness

- XLPE: Excellent electrical properties and resistance to abrasion

Other Materials

- Shielding: Braided or foil-based materials used to reduce electromagnetic interference

- Connectors: Used to terminate wires and connect them to other components

- Jackets: Outer protective layer that provides abrasion, moisture, and temperature resistance

7. How do you ensure the quality and reliability of harness assemblies?

- Follow industry standards and best practices

- Use high-quality materials and components

- Implement quality control measures throughout the manufacturing process

- Conduct thorough inspections and testing before shipment

- Provide clear and detailed documentation

8. Describe the use of specialized tools and equipment in harness installation.

- Wire strippers and crimpers

- Cable ties and zip guns

- Cable trays and conduits

- Harness boards and templates

- Multimeters and diagnostic tools

9. What are some common challenges faced by harness installers and how do you overcome them?

Challenges

- Tight installation spaces

- Complex routing requirements

- Electromagnetic interference

- Time constraints

Solutions

- Use flexible materials and cable management techniques

- Plan and route harnesses carefully to avoid conflicts

- Employ shielding and grounding techniques to minimize interference

- Prioritize tasks and work efficiently to meet deadlines

10. How do you stay up-to-date with industry best practices and advancements in harness installation?

- Attend industry conferences and workshops

- Read trade publications and technical articles

- Obtain certifications and training

- Network with other professionals in the field

- Stay informed about new materials, tools, and technologies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Harness Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Harness Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Harness Installer is responsible for assembling, installing, and inspecting wire harnesses and associated components for various electrical systems, ensuring proper functionality and compliance with industry standards.

1. Installation and Assembly

Install and assemble wire harnesses according to blueprints, schematics, and specifications.

- Inspect components for correctness and proper preparation.

- Route, bundle, and secure wires using various techniques, such as lacing, tying, and clamping.

2. Testing and Inspection

Conduct comprehensive testing and inspection procedures to verify the integrity and functionality of installed harnesses.

- Perform continuity, insulation, and voltage drop tests to ensure electrical performance.

- Inspect for proper connections, routing, and adherence to specifications.

3. Troubleshooting and Repair

Identify and resolve any issues or defects in wire harnesses or associated components during or after installation.

- Troubleshoot electrical problems using test equipment and technical knowledge.

- Replace or repair defective components and re-test to ensure proper functioning.

4. Documentation and Reporting

Maintain accurate records and documentation of installation and testing procedures for quality control purposes.

- Record any deviations from specifications or unusual occurrences.

- Provide reports on work progress and findings to supervisors and clients.

Interview Tips

Preparing for a Harness Installer interview requires a combination of technical knowledge and communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, thoroughly research the company’s industry, products or services, and the specific role you’re applying for. This will demonstrate your interest and enthusiasm, and it will allow you to ask informed questions during the interview.

- Be prepared to discuss your understanding of the company’s business and the industry in general.

- Have a clear idea of the key responsibilities and qualifications for the Harness Installer position.

2. Highlight Your Technical Skills and Experience

During the interview, emphasize your technical skills and experience in harness installation. Provide specific examples of your work, and be prepared to discuss the methods and tools you use to ensure accuracy and quality.

- Showcase your knowledge of wire harnessing techniques, such as lacing, tying, and clamping.

- Describe your experience with electrical testing and troubleshooting procedures.

3. Demonstrate Your Attention to Detail

Harness installers must have a keen eye for detail and precision. In the interview, highlight your ability to follow instructions carefully, adhere to specifications, and perform meticulous inspections.

- Provide examples of how you have successfully identified and resolved errors in harness assemblies.

- Explain your approach to quality control and maintaining high standards in your work.

4. Emphasize Your Problem-Solving Abilities

Harness installers often encounter challenges during installation and troubleshooting. Be prepared to share examples of how you have approached and solved problems effectively.

- Describe a situation where you had to troubleshoot an electrical issue in a wire harness.

- Explain the steps you took to identify the root cause and implement a solution.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Harness Installer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!