Are you gearing up for an interview for a Precision Aircraft Structure Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Precision Aircraft Structure Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

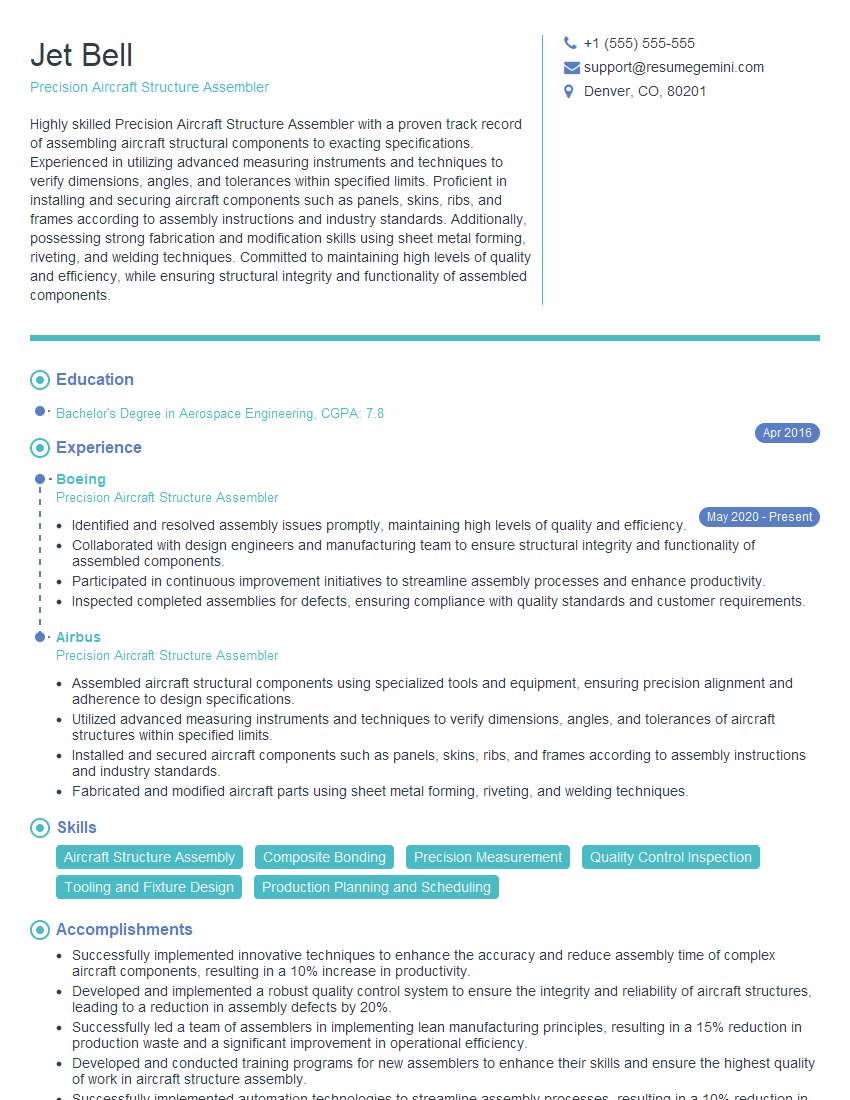

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Precision Aircraft Structure Assembler

1. Explain the key steps involved in the aircraft structure assembly process.

Detailed Answer:

- Planning and Preparation: Review blueprints, gather materials, and set up the assembly area.

- Component Fabrication: Create individual aircraft components, such as wings, fuselage, and empennage.

- Assembly of Major Components: Join major aircraft sections, including the wing-to-fuselage and fuselage-to-empennage assemblies.

- System Installation: Integrate electrical, hydraulic, and mechanical systems into the assembled structure.

- Final Assembly and Inspection: Complete the assembly process, conduct thorough inspections, and prepare the aircraft for flight testing.

2. Describe the different types of materials used in aircraft structure assembly.

Detailed Answer:

- Aluminum Alloys: Lightweight, strong, and corrosion-resistant, used for fuselage, wings, and empennage.

- Titanium Alloys: Strong, lightweight, and heat-resistant, used for engine components and structural elements.

- Composite Materials: Lightweight, durable, and adaptable, used for wings, fuselage, and other structures.

- Steel: Strong and cost-effective, used for landing gear, spars, and other high-stress components.

- Specialized Materials: Such as ceramics, polymers, and coatings, for specific applications like thermal protection and electrical insulation.

3. Describe the role of jigs and fixtures in aircraft structure assembly.

Detailed Answer:

- Jigs: Positioning and holding devices that ensure precise alignment and support of components during assembly.

- Fixtures: Tools that hold components in specific positions for drilling, riveting, welding, and other operations.

- Advantages: Accuracy, consistency, increased productivity, and enhanced safety.

4. Explain the importance of adhering to assembly tolerances and specifications.

Detailed Answer:

- Structural Integrity: Ensures that the assembled aircraft meets design specifications and can withstand flight loads.

- Performance: Maintains optimal aerodynamic efficiency and system functionality.

- Safety: Prevents failures and accidents by ensuring components are assembled correctly.

- Regulatory Compliance: Meets certification standards set by aviation authorities.

5. How do you ensure the proper fit and alignment of components during assembly?

Detailed Answer:

- Verification of Dimensions: Using precision measuring tools to confirm that components meet specified dimensions.

- Use of Alignment Tools: Employing jigs, fixtures, and specialized tools to maintain proper alignment.

- Regular Inspections: Conducting inspections throughout the assembly process to identify and correct any discrepancies.

- Collaboration with Engineers: Consulting with design engineers for guidance on tolerance requirements and assembly procedures.

6. Describe your experience with riveting techniques used in aircraft structure assembly.

Detailed Answer:

- Hand Riveting: Manually installing rivets using hand tools for small-scale or difficult-to-access areas.

- Pneumatic Riveting: Utilizing pneumatic tools that deliver high-impact force for consistent and efficient riveting.

- Robotic Riveting: Employing automated robotic systems for high-volume and repetitive applications.

7. Explain the process of bonding aircraft composite materials.

Detailed Answer:

- Surface Preparation: Thorough cleaning and preparation of composite surfaces to ensure proper adhesion.

- Application of Adhesive: Applying specialized adhesives to the mating surfaces, using manual or automated methods.

- Curing Process: Controlling temperature and pressure during curing to achieve optimal bond strength.

- Quality Assurance: Conducting non-destructive testing and visual inspections to verify bond integrity.

8. How do you interpret and follow technical drawings and specifications related to aircraft structure assembly?

Detailed Answer:

- Blueprint Reading: Understanding the symbols, dimensions, and annotations on technical drawings.

- Specification Interpretation: Interpreting written instructions and requirements related to assembly procedures and materials.

- Collaboration with Designers: Seeking clarification or additional information from design engineers when necessary.

9. Describe your experience with using specialized equipment for aircraft structure assembly.

Detailed Answer:

- Riveting Machines: Proficient in operating hand, pneumatic, and robotic riveting machines.

- Bonding Equipment: Familiar with the use of adhesive dispensers, curing ovens, and non-destructive testing equipment.

- Assembly Jigs: Experienced in setting up and utilizing jigs and fixtures for precise assembly.

10. Explain how you maintain a safe and efficient work environment in an aircraft structure assembly setting.

Detailed Answer:

- Following Safety Protocols: Adhering to established safety regulations and wearing appropriate personal protective equipment.

- Housekeeping: Maintaining a clean and organized work area to prevent accidents.

- Ergonomics: Practicing proper lifting techniques and using ergonomic tools to reduce strain and fatigue.

- Communication: Communicating effectively with colleagues and supervisors to ensure a safe work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Precision Aircraft Structure Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Precision Aircraft Structure Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Precision Aircraft Structure Assemblers work in a fast-paced environment, often requiring great attention to detail and the ability to meet strict deadlines. They are responsible for assembling various aircraft components, from small parts to large sections, using specialized tooling and equipment. Some of their key responsibilities may include:

1. Assembly of Aircraft Components

Assembling various aircraft components such as fuselage panels, wings, and landing gears according to blueprints and specifications.

- Following detailed schematics, blueprints, and work orders to ensure precise assembly.

- Inspecting parts for defects and ensuring all components meet required tolerances and quality standards.

- Using specialized tools and equipment, including riveting guns, drills, and torque wrenches, in the assembly process.

2. Riveting, Bonding, and Sealing

Performing riveting, bonding, and sealing operations to join and secure aircraft components.

- Installing and driving rivets to fasten metal parts, ensuring proper flushness and tightness.

- Applying adhesives and sealants to bond components, preventing leaks and ensuring structural integrity.

- Inspecting and testing riveted and bonded joints to verify their strength and reliability.

3. Handling and Storage of Materials

Handling and storing materials and components properly to prevent damage or contamination.

- Maintaining a clean and organized work area, ensuring parts are safely stored and protected from damage.

- Following proper material handling procedures to prevent scratches, dents, or other defects during transportation and storage.

- Adhering to inventory control practices, tracking materials and components to ensure availability.

4. Quality Control and Inspection

Performing quality control inspections and tests to ensure assembled components meet specifications.

- Inspecting completed assemblies for dimensional accuracy, surface finish, and overall quality.

- Conducting non-destructive testing (NDT) techniques, such as ultrasonic or radiographic inspection, to detect defects or flaws.

- Recording and documenting inspection results, providing feedback to improve assembly processes.

Interview Tips

To prepare for an interview as a Precision Aircraft Structure Assembler, consider the following tips:

1. Research the Company and Position

Before the interview, take the time to research the company’s background, industry, and specific requirements for the position. Understanding the company’s culture and values will help you demonstrate your alignment with their goals.

2. Practice Answering Common Interview Questions

Prepare for common interview questions, such as those related to your experience, skills, and knowledge of the industry. Practice your answers concisely and highlight your relevant qualifications.

For instance, you may prepare for questions like:

- “Describe your experience in assembling aircraft components.”

- “How do you ensure the quality and accuracy of your work?”

- “What are some challenges you’ve faced as an Aircraft Structure Assembler, and how did you overcome them?”

3. Showcase Your Attention to Detail

Emphasize your keen eye for detail and precision in your answers. Provide examples of how you have consistently met or exceeded quality standards in your previous roles.

4. Highlight Relevant Skills and Experiences

Tailor your responses to highlight the skills and experiences that are most relevant to the job description. Quantify your accomplishments whenever possible to demonstrate the impact of your contributions.

5. Be Enthusiastic and Professional

Throughout the interview, display enthusiasm for the industry and the opportunity to contribute to the company’s success. Maintain a professional demeanor, dress appropriately, and arrive on time.

6. Ask Thoughtful Questions

At the end of the interview, prepare a few well-thought-out questions to ask the interviewer. This demonstrates your interest in the position and the company, and it also gives you an opportunity to gather additional information.

7. Follow Up

After the interview, send a brief thank-you note to the interviewer. Reiterate your interest in the position and express your appreciation for the opportunity to meet their team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Precision Aircraft Structure Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!