Are you gearing up for an interview for a Wire Coiler Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wire Coiler Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

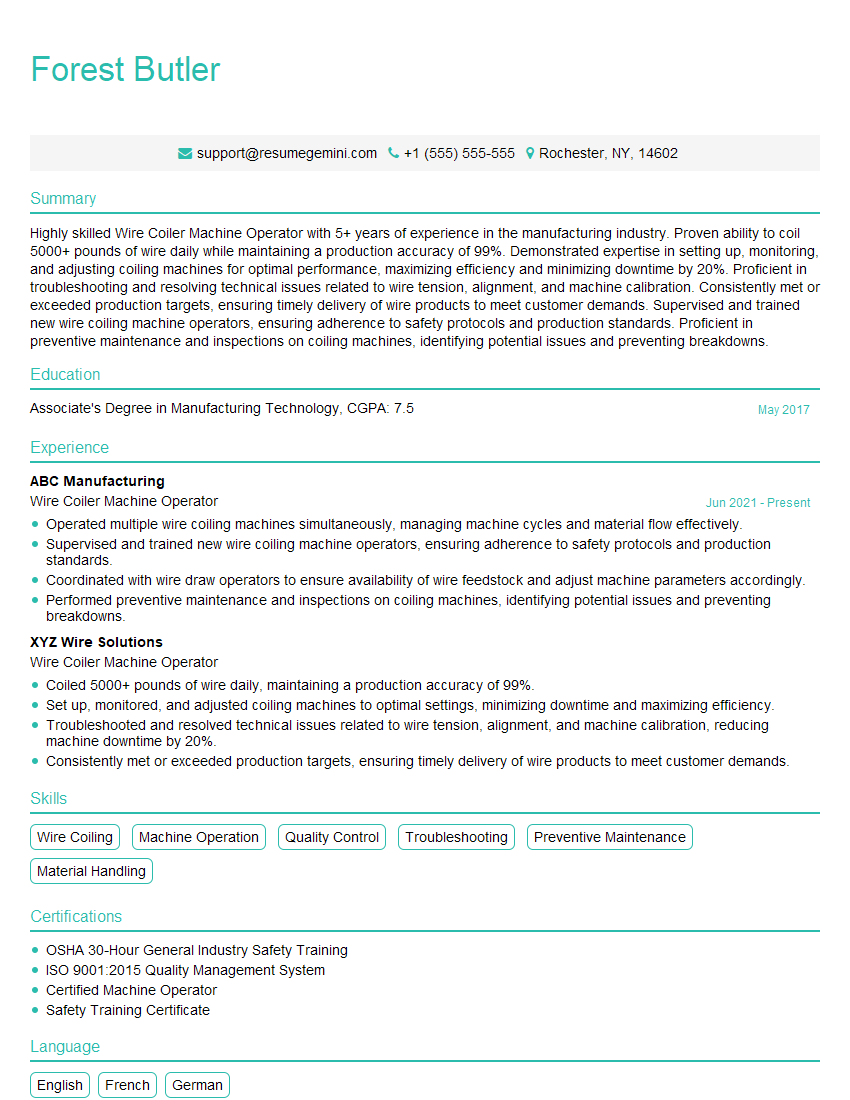

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Coiler Machine Operator

1. Describe the steps involved in setting up and operating a wire coiling machine?

- Load the wire onto the machine.

- Set the machine’s tension and speed settings.

- Thread the wire through the machine’s guides.

- Start the machine and monitor its operation.

- Make adjustments to the machine’s settings as needed.

2. What are the different types of wire coils that can be produced on a wire coiling machine?

Coils with different diameters

- Small coils

- Medium coils

- Large coils

Coils with different shapes

- Round coils

- Square coils

- Rectangular coils

3. What are the safety precautions that should be taken when operating a wire coiling machine?

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Keep the work area clean and free of debris.

- Do not operate the machine if it is damaged or malfunctioning.

- Follow the manufacturer’s instructions for operating the machine.

4. What are the common problems that can occur when operating a wire coiling machine, and how can they be resolved?

- Wire breakage: This can be caused by a number of factors, including incorrect tension settings, worn guides, or a damaged wire. To resolve the problem, check the tension settings, replace the guides, or replace the wire.

- Coil distortion: This can be caused by incorrect speed settings, uneven tension, or a damaged machine. To resolve the problem, check the speed settings, adjust the tension, or repair the machine.

- Machine malfunction: This can be caused by a number of factors, including electrical problems, mechanical problems, or software problems. To resolve the problem, troubleshoot the machine and repair or replace the faulty components.

5. What are the different types of materials that can be coiled on a wire coiling machine?

- Copper

- Steel

- Aluminum

- Brass

- Plastic

6. How do you ensure that the coils produced on the wire coiling machine meet the specified quality standards?

- Follow the manufacturer’s instructions for operating the machine.

- Use high-quality materials.

- Inspect the coils after they are produced.

- Make adjustments to the machine’s settings as needed.

7. What are the different types of tooling that can be used on a wire coiling machine?

- Wire guides

- Tensioners

- Cutters

- Formers

- Dies

8. How do you troubleshoot a wire coiling machine that is not operating properly?

- Check the power supply.

- Check the machine’s settings.

- Inspect the machine for any damage.

- Refer to the manufacturer’s troubleshooting guide.

9. How do you maintain a wire coiling machine?

- Clean the machine regularly.

- Lubricate the machine’s moving parts.

- Inspect the machine’s electrical connections.

- Calibrate the machine’s sensors.

10. What are the different types of wire coiling machines?

- Manual wire coiling machines

- Semi-automatic wire coiling machines

- Automatic wire coiling machines

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Coiler Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Coiler Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wire Coiler Machine Operators play a vital role in manufacturing and industrial settings, ensuring the smooth and efficient winding of wires onto coils. Their key job responsibilities encompass:

1. Coil Preparation

Prepares coils by applying adhesive, lubrication, and insulation as per specifications and ensuring proper alignment for efficient winding.

2. Machine Operation

Operates and monitors wire coiling machines to wind wires onto coils, adhering to predetermined tension, speed, and winding patterns.

3. Quality Control

Inspects and tests coils after winding to ensure conformity with quality standards, including dimensions, electrical properties, and insulation integrity.

4. Machine Maintenance

Performs preventive maintenance and repairs on coiling machines to maintain optimal performance and minimize downtime.

Interview Tips

To ace an interview for a Wire Coiler Machine Operator position, candidates should prepare thoroughly and showcase their skills and experience.

1. Research the Company and Industry

Research the company’s products, services, and industry to demonstrate your understanding of their business and align your qualifications accordingly.

2. Highlight Relevant Skills and Experience

Emphasize your expertise in wire coiling techniques, machine operation, and quality control. Provide specific examples that showcase your abilities.

3. Prepare for Technical Questions

Review common technical questions related to wire coiling, such as winding patterns, tension control, and troubleshooting techniques. Prepare concise and informed answers.

4. Practice Problem-Solving Situations

Think through potential problem-solving scenarios that you may encounter on the job, such as equipment malfunctions or quality defects. Explain your approach to these situations.

5. Demonstrate Safety Awareness

Emphasize your adherence to safety protocols and your understanding of the importance of operating equipment safely in a manufacturing environment.

6. Ask Thoughtful Questions

Asking relevant questions about the position, the company, and the industry demonstrates your interest and eagerness to learn more.

Next Step:

Now that you’re armed with the knowledge of Wire Coiler Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wire Coiler Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini