Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wire Wrapping Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

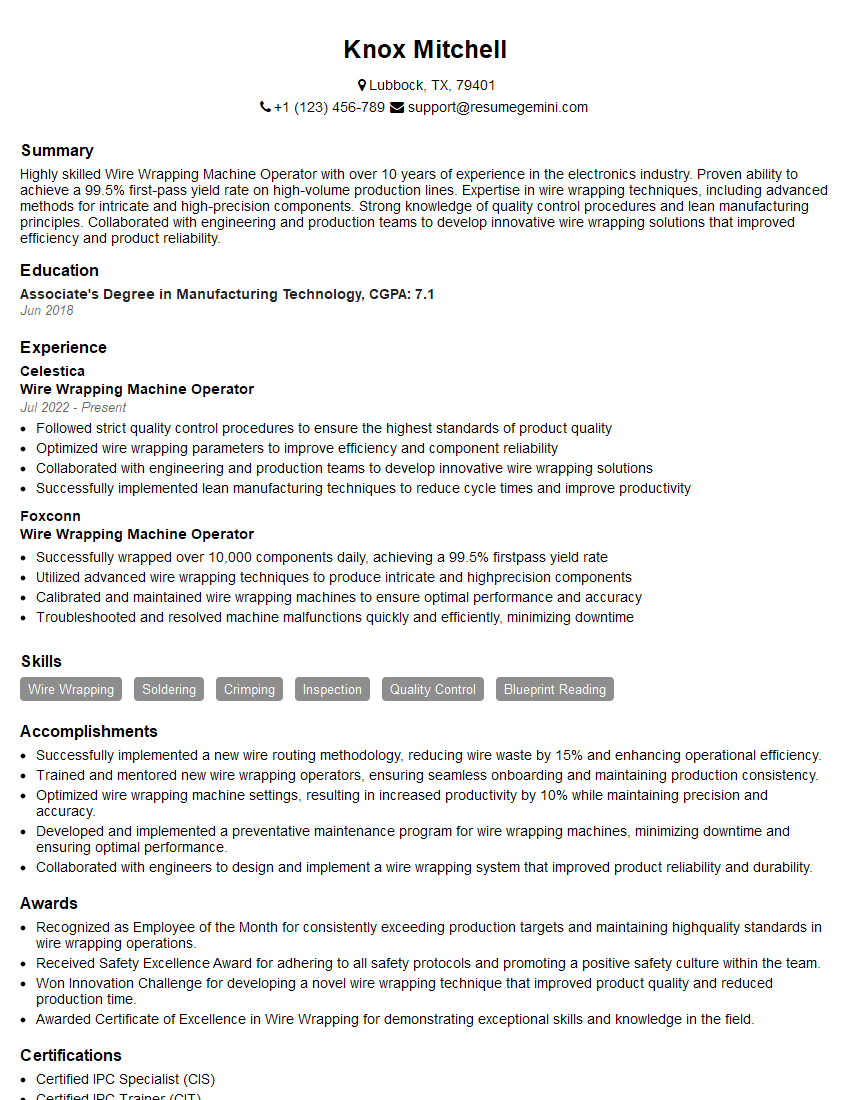

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Wrapping Machine Operator

1. What are the key tasks and responsibilities of a Wire Wrapping Machine Operator?

As a Wire Wrapping Machine Operator, my primary responsibilities include:

- Setting up and operating wire wrapping machines to produce coils, transformers, and other electrical components.

- Loading and unloading wire onto the machine and ensuring proper tension for precise wrapping.

- Monitoring the wrapping process to ensure quality and accuracy.

- Performing preventive maintenance and calibrating the machine to maintain optimal performance.

- Identifying and troubleshooting any machine malfunctions or product defects.

2. What types of wire wrapping machines have you worked with?

Machines I have experience with include:

- Semi-automatic benchtop wire wrapping machines

- High-speed automated coil winding machines

- Computer-controlled wire bonding machines

For each type, I am familiar with:

- Their different capabilities and applications.

- The setup, operation, and maintenance procedures.

- The potential troubleshooting issues and how to resolve them.

3. How do you ensure the quality and accuracy of the wire wrapping process?

To ensure quality and accuracy, I follow a systematic approach that involves:

- Thoroughly inspecting the raw materials, including wire and insulation.

- Selecting the appropriate machine settings based on the product specifications.

- Continuously monitoring the wrapping process visually and using quality control tools.

- Performing regular inspections and measurements to verify product dimensions and electrical properties.

- Adhering to established quality standards and industry best practices.

4. What troubleshooting techniques do you use when dealing with machine malfunctions?

When troubleshooting machine malfunctions, I follow a logical and systematic approach:

- Identifying the problem and its potential causes through observation and analysis.

- Referencing technical manuals and diagrams to understand the machine’s components and functions.

- Performing diagnostic tests and inspections to isolate the issue.

- Applying appropriate repair techniques, such as replacing faulty parts or adjusting settings.

- Thoroughly testing the machine after repairs to ensure it is functioning properly.

5. What are some of the safety precautions you take while operating wire wrapping machines?

Safety is paramount when operating wire wrapping machines. I adhere to the following precautions:

- Wearing appropriate personal protective equipment, such as safety glasses and gloves.

- Ensuring that the machine is properly grounded and all electrical connections are secure.

- Keeping the work area clean and free of debris to prevent tripping or entanglement.

- Following established lockout/tagout procedures when performing maintenance or repairs.

- Being aware of potential hazards, such as moving parts, sharp edges, and electrical shock.

6. How do you stay updated on the latest advancements in wire wrapping technology?

To stay up-to-date on the latest advancements in wire wrapping technology, I:

- Attend industry conferences and workshops.

- Read technical journals and trade publications.

- Network with other wire wrapping professionals.

- Participate in online forums and discussion groups.

- Seek training and certification opportunities provided by manufacturers or third-party organizations.

7. What is your approach to continuous improvement in the wire wrapping process?

I am committed to continuous improvement in the wire wrapping process by:

- Analyzing production data and identifying areas for optimization.

- Suggesting and implementing process improvements, such as reducing setup time or increasing efficiency.

- Collaborating with colleagues and supervisors to share ideas and best practices.

- Seeking feedback from customers to gather insights into product quality and satisfaction.

- Staying informed about new technologies and adopting them if they have the potential to enhance the process.

8. How do you handle high-volume or urgent orders?

When handling high-volume or urgent orders, I prioritize tasks and allocate resources effectively:

- Analyzing the production schedule and identifying critical deadlines.

- Optimizing machine settings and production processes to increase capacity.

- Working overtime or additional shifts if necessary to meet demand.

- Coordinating with colleagues to ensure smooth material flow and timely delivery.

- Communicating regularly with supervisors and customers to provide updates and address any concerns.

9. What is your understanding of the electrical properties and specifications of wire wrapping?

I am familiar with the electrical properties and specifications of wire wrapping, including:

- Conductor types and their electrical conductivity.

- Insulation materials and their dielectric strength.

- Wire gauge and its impact on current-carrying capacity.

- Turn ratios and their effect on inductance and capacitance.

- The importance of proper wire wrapping techniques to ensure electrical integrity and minimize resistance.

10. How do you ensure that the wire wrapping meets the required specifications and standards?

To ensure that the wire wrapping meets the required specifications and standards, I follow these steps:

- Thoroughly reviewing product drawings and specifications.

- Selecting the appropriate wire and insulation materials based on electrical properties.

- Calibrating the wire wrapping machine to meet the required winding parameters.

- Performing regular checks during the wrapping process to monitor quality.

- Using testing equipment to verify electrical performance, such as resistance, inductance, and capacitance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Wrapping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Wrapping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wire Wrapping Machine Operators are responsible for operating machines that wrap wires around electrical components. Their duties include:

1. Machine Operation

– Loading wire into the machine

– Setting up and adjusting the machine

– Monitoring the machine during operation

2. Quality Control

– Inspecting wrapped components for defects

– Ensuring that components meet specifications

– Troubleshooting and resolving any issues

3. Maintenance

– Cleaning and lubricating the machine

– Performing minor repairs

– Assisting with major repairs

4. Safety

– Following all safety protocols

– Maintaining a clean and organized work area

– Wearing appropriate safety gear

Interview Tips

To ace the interview for a Wire Wrapping Machine Operator position, it is important to:

1. Research the Company and Position

– Understand the company’s products, services, and culture

– Read the job description carefully and identify the key requirements

2. Prepare for Common Interview Questions

– Practice answering questions about your experience with wire wrapping machines

– Prepare examples of your quality control and troubleshooting skills

– Be ready to discuss your safety knowledge

3. Dress Professionally and Arrive on Time

– First impressions matter, so dress appropriately for the interview

– Punctuality shows respect for the interviewer’s time

4. Be Enthusiastic and Confident

– Show the interviewer that you are excited about the opportunity

– Believe in your abilities and communicate your confidence

5. Ask Questions

– Show interest in the job by asking thoughtful questions

– Prepare a few questions about the company, the position, and the interviewer’s expectations

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wire Wrapping Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wire Wrapping Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.