Feeling lost in a sea of interview questions? Landed that dream interview for Battery Parts Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Battery Parts Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

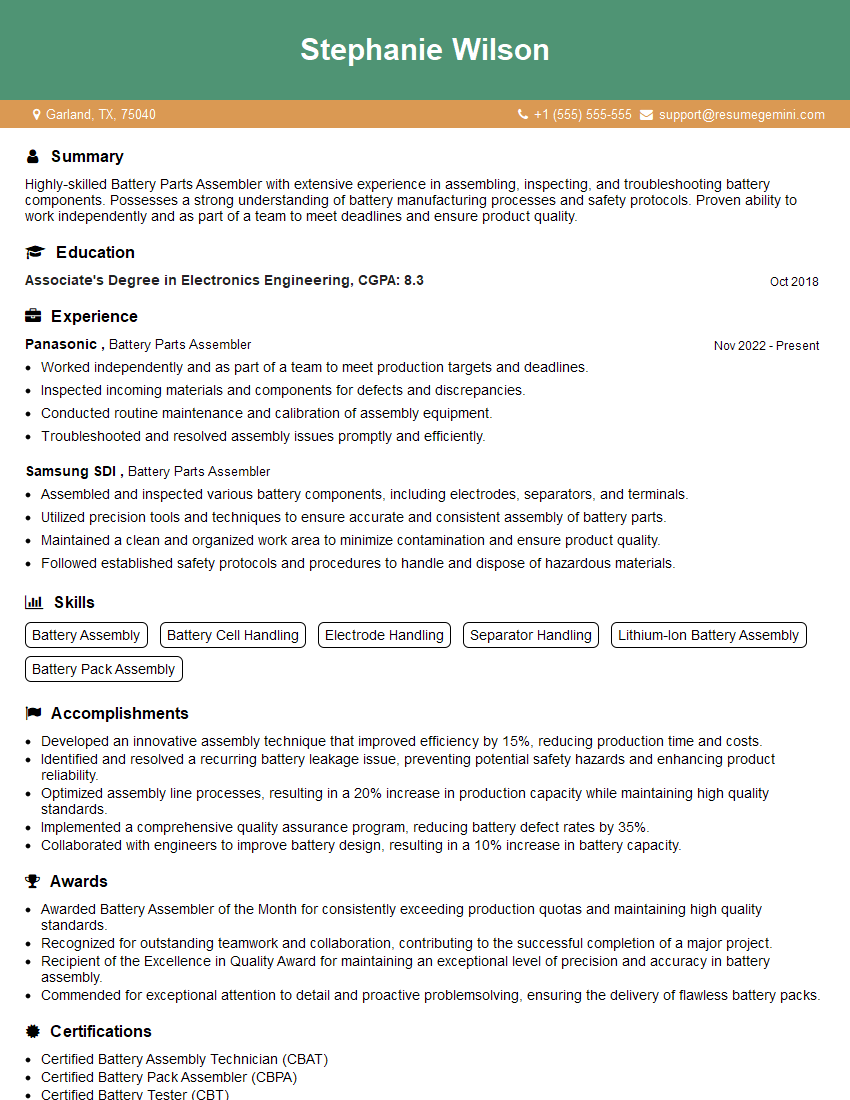

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Battery Parts Assembler

1. What are the different types of batteries and their applications?

- Lithium-ion batteries are commonly used in portable electronics such as laptops, smartphones, and tablets.

- Lead-acid batteries are used in vehicles, providing power to start the engine and operate electrical systems.

- Nickel-cadmium batteries are rechargeable batteries often used in power tools and medical devices.

- Alkaline batteries are single-use batteries commonly found in flashlights, toys, and remote controls.

2. What are the key performance characteristics of a battery?

Capacity

- Measures the amount of charge a battery can hold, typically measured in amp-hours (Ah).

- A higher capacity battery can provide power for longer durations.

Voltage

- Refers to the electrical potential difference between the battery’s terminals, measured in volts (V).

- Determines the operating voltage of the devices it powers.

Power Density

- Measures the amount of energy stored per unit volume or mass, typically expressed in watt-hours per kilogram (Wh/kg).

- Indicates how compact and lightweight the battery is for a given capacity.

3. What are the safety precautions to consider when working with batteries?

- Avoid short-circuiting batteries, as this can cause overheating and potential fire hazards.

- Do not overcharge or over-discharge batteries, as this can damage the cells and reduce their lifespan.

- Handle and store batteries in a cool, dry place to prevent degradation.

- Wear appropriate personal protective equipment (PPE), such as gloves and eye protection, when working with batteries.

4. What are the different methods of battery assembly?

- Manual assembly involves assembling battery components by hand using tools such as screwdrivers and soldering irons.

- Automated assembly utilizes machines and robotics to assemble batteries with greater precision and efficiency.

- Hybrid assembly combines manual and automated processes to achieve a balance of speed, accuracy, and cost-effectiveness.

5. What are the quality control measures implemented in battery assembly?

- Visual inspection for defects or inconsistencies in components and assembly.

- Electrical testing to verify battery voltage, capacity, and power output.

- Temperature monitoring to ensure batteries operate within safe temperature ranges.

- Data logging and documentation to track assembly processes and identify areas for improvement.

6. What are the common challenges faced during battery assembly and how do you overcome them?

- Soldering issues: Address by using appropriate soldering techniques, flux, and maintaining proper soldering equipment.

- Component alignment: Overcome through precision tools, fixtures, and jigs to ensure accurate placement of components.

- Battery performance variation: Minimize by using high-quality components, optimizing assembly processes, and implementing statistical process control.

7. What are the emerging trends in battery assembly technology?

- Additive manufacturing (3D printing) for rapid prototyping and customized assembly.

- Advanced battery management systems for monitoring and optimizing battery performance.

- Flexible and printable batteries for use in wearable and IoT devices.

8. How do you ensure the safety of battery packs during assembly and handling?

- Follow proper grounding procedures to prevent electrostatic discharge.

- Use insulated tools and protective gear to minimize the risk of electrical shocks.

- Store batteries in designated, well-ventilated areas away from heat sources.

- Implement safety protocols for handling damaged or defective batteries.

9. What techniques do you employ to minimize waste and improve efficiency in battery assembly?

- Optimize component layout and reduce lead times through process mapping.

- Implement lean manufacturing principles to minimize waste and improve productivity.

- Reuse and recycle materials whenever possible, reducing environmental impact.

10. How do you stay updated with the latest advancements in battery technology and assembly techniques?

- Attend industry conferences and workshops.

- Read technical journals and research papers.

- Collaborate with engineers and researchers.

- Seek opportunities for training and professional development.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Battery Parts Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Battery Parts Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Assemble Battery Parts with Precision

Assemble various battery components accurately, including terminals, connectors, and electrodes, ensuring precise alignment and adherence to specifications.

2. Perform Quality Inspection and Testing

Conduct thorough inspections to ensure parts are free from defects and meet quality standards. Perform functional testing to verify the performance and reliability of the assembled batteries.

3. Maintain Work Area and Equipment

Keep the work area clean, organized, and safe. Perform routine maintenance on assembly equipment to ensure optimal operation and prevent downtime.

4. Follow Safety Procedures and Regulations

Adhere to all safety regulations and guidelines to create a hazard-free work environment. Wear appropriate safety gear and handle battery materials responsibly.

Interview Preparation Tips

1. Research the Company and Industry

Gather information about the company’s history, mission, and products. Familiarize yourself with industry trends and technological advancements related to battery assembly.

2. Practice Answering Common Interview Questions

Prepare for questions about your experience, skills, and motivation for the role. Rehearse your responses, focusing on highlighting your relevant abilities and enthusiasm for battery assembly.

- Example Outline:

- Tell me about your experience in assembling battery parts.

- Describe a time you solved a problem or improved a process in battery assembly.

- How do you ensure that the assembled batteries meet quality standards?

3. Quantify Your Accomplishments

When describing your previous experience, quantify your accomplishments whenever possible. Use specific numbers, metrics, or examples to demonstrate your impact and value.

- Example: “I successfully assembled over 10,000 batteries per month, consistently meeting or exceeding quality standards.”

4. Be Enthusiastic and Passionate

Show your genuine interest in battery assembly and the industry. Enthusiasm and passion can make a positive impression and demonstrate your commitment to the role.

5. Dress Professionally and Arrive Punctually

Presentation and punctuality matter. Dress appropriately for the interview and arrive on time to show respect and attention to detail.

Next Step:

Now that you’re armed with the knowledge of Battery Parts Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Battery Parts Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini