Are you gearing up for an interview for a Hand Printed Circuit Board Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hand Printed Circuit Board Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

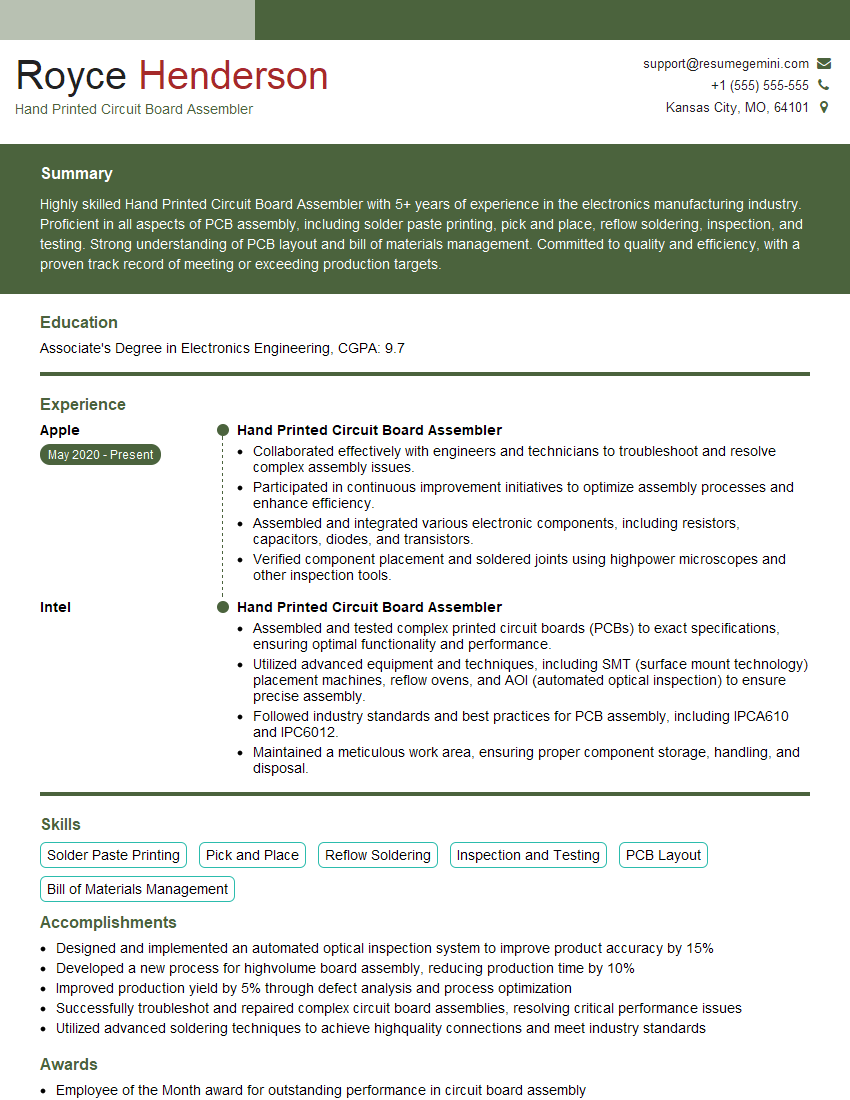

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Printed Circuit Board Assembler

1. Explain the process of hand assembling a printed circuit board (PCB)?

The process of hand assembling a printed circuit board (PCB) involves several steps:

- Gather the necessary materials, including the PCB, components, solder paste, and soldering iron.

- Apply solder paste to the designated pads on the PCB.

- Place the components onto the PCB, ensuring correct orientation and alignment.

- Solder the components in place using the soldering iron.

- Inspect the PCB for any errors or defects.

- Clean the PCB to remove any flux or solder residue.

- Test the PCB to ensure it is functioning correctly.

2. What are the different types of components that can be hand assembled onto a PCB?

Passive Components

- Resistors

- Capacitors

- Inductors

- Diodes

Active Components

- Transistors

- Integrated circuits (ICs)

- Microcontrollers

- Sensors

3. What are the common defects that can occur during hand assembly of a PCB?

Common defects that can occur during hand assembly of a PCB include:

- Solder bridges: Occurs when solder connects two or more pads that should not be connected.

- Solder voids: Occurs when there is insufficient solder on a joint.

- Tombstones: Occurs when a component is not fully seated on the PCB and one end is lifted off the board.

- Flipped components: Occurs when a component is placed on the PCB with the incorrect orientation.

- Missing components: Occurs when a component is not placed on the PCB at all.

4. What techniques can be used to prevent defects during hand assembly of a PCB?

Techniques to prevent defects during hand assembly of a PCB include:

- Using a magnifying glass or microscope to inspect components and joints.

- Using proper soldering techniques, such as the correct temperature and solder application.

- Inspecting the PCB thoroughly after assembly for any defects.

- Using a continuity tester or other diagnostic tools to verify the functionality of the PCB.

- Following the assembly instructions carefully and adhering to industry standards.

5. What are the safety precautions that should be taken when hand assembling a PCB?

Safety precautions that should be taken when hand assembling a PCB include:

- Wearing appropriate safety gear, such as safety glasses and gloves.

- Working in a well-ventilated area.

- Using soldering equipment with proper grounding.

- Avoiding contact with hot components or solder.

- Being aware of the potential for electrostatic discharge (ESD).

6. What quality control measures are typically used to ensure the reliability of hand assembled PCBs?

Quality control measures used to ensure the reliability of hand assembled PCBs include:

- Visual inspection of the PCB for defects.

- Electrical testing to verify functionality.

- Burn-in testing to identify potential failures.

- Environmental testing to assess the PCB’s performance under various conditions.

- Statistical process control (SPC) to monitor and improve assembly processes.

7. What are the advantages of using hand assembly for PCBs?

Advantages of using hand assembly for PCBs include:

- Flexibility: Hand assembly allows for customization and rapid prototyping.

- Precision: Skilled assemblers can achieve high accuracy and precision in component placement.

- Cost-effectiveness: Hand assembly can be cost-effective for small production runs or complex assemblies.

- Quality: Hand assembly ensures careful attention to detail and reduces the risk of defects.

- Reliability: Hand assembled PCBs are highly reliable due to the individual care and inspection involved.

8. What are the disadvantages of using hand assembly for PCBs?

Disadvantages of using hand assembly for PCBs include:

- Speed: Hand assembly is slower than automated assembly methods.

- Scalability: Hand assembly is not suitable for high-volume production.

- Consistency: Quality can vary between different assemblers.

- Cost: Hand assembly can be more expensive than automated assembly for large production runs.

- Repetitive work: Hand assembly can be repetitive and may not be suitable for all individuals.

9. What is your experience with hand assembling different types of PCBs?

I have extensive experience in hand assembling various types of PCBs, including:

- Single-sided PCBs

- Double-sided PCBs

- Multilayer PCBs

- Surface mount PCBs

- Through-hole PCBs

- Mixed-technology PCBs

I have worked on PCBs for a wide range of applications, including:

- Consumer electronics

- Industrial controls

- Medical devices

- Automotive electronics

- Telecommunications equipment

10. What are your strengths and weaknesses as a Hand Printed Circuit Board Assembler?

Strengths

- Excellent attention to detail and precision

- Strong knowledge of electronic components and assembly techniques

- Ability to work independently and as part of a team

- Experience with a variety of PCB types and applications

- Commitment to quality and accuracy

Weaknesses

- Speed may be slower than automated assembly methods

- May not be suitable for high-volume production

- Repetitive work can be tedious at times

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Printed Circuit Board Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Printed Circuit Board Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hand Printed Circuit Board Assemblers are responsible for assembling printed circuit boards (PCBs) by hand, using a variety of tools and materials. Their key responsibilities include:

1. Component Placement

Placing electronic components, such as resistors, capacitors, and diodes, onto the PCB according to specifications.

- Verifying the correct placement and orientation of components

- Ensuring that components are securely attached to the board

2. Soldering

Soldering components to the PCB to create electrical connections.

- Using soldering equipment to apply solder to the connections

- Inspecting solder joints to ensure proper bonding

3. Final Assembly

Completing the assembly process by attaching additional components, such as connectors and heat sinks.

- Installing screws or bolts to secure components

- Applying adhesives or coatings for protection

4. Quality Control

Inspecting and testing PCBs to ensure they meet quality standards.

- Using visual inspection and testing equipment to identify defects

- Troubleshooting and repairing any problems identified during inspection

Interview Tips

To ace an interview for a Hand Printed Circuit Board Assembler position, candidates should prepare thoroughly and showcase their skills and experience. Here are some tips and hacks:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry to demonstrate your interest and understanding of their business. Study the job description carefully to identify the specific responsibilities and qualifications required.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in component placement, soldering, and final assembly. Quantify your experience with specific projects and results whenever possible. For instance, instead of saying “I have experience in soldering,” say “I have soldered over 10,000 components with a defect rate of less than 1%.”

3. Demonstrate Attention to Detail

Hand Printed Circuit Board Assemblers need to have excellent attention to detail. In the interview, provide examples of your ability to work accurately and follow instructions precisely. You can also mention any quality control measures you have implemented in previous roles.

4. Showcase Problem-Solving Abilities

Assemblers may encounter problems during the manufacturing process. Highlight your problem-solving skills by describing instances where you identified and resolved issues. Explain the steps you took to troubleshoot the problem and implement a solution.

5. Prepare Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare questions that demonstrate your understanding of the role and your eagerness to learn more about the organization.

6. Practice

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the actual interview.

7. Dress Professionally

First impressions matter, so dress appropriately for the interview. Consider business attire or business casual, depending on the company culture.

Next Step:

Now that you’re armed with the knowledge of Hand Printed Circuit Board Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Hand Printed Circuit Board Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini