Are you gearing up for an interview for a Industrial Furnace Fabricator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Industrial Furnace Fabricator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

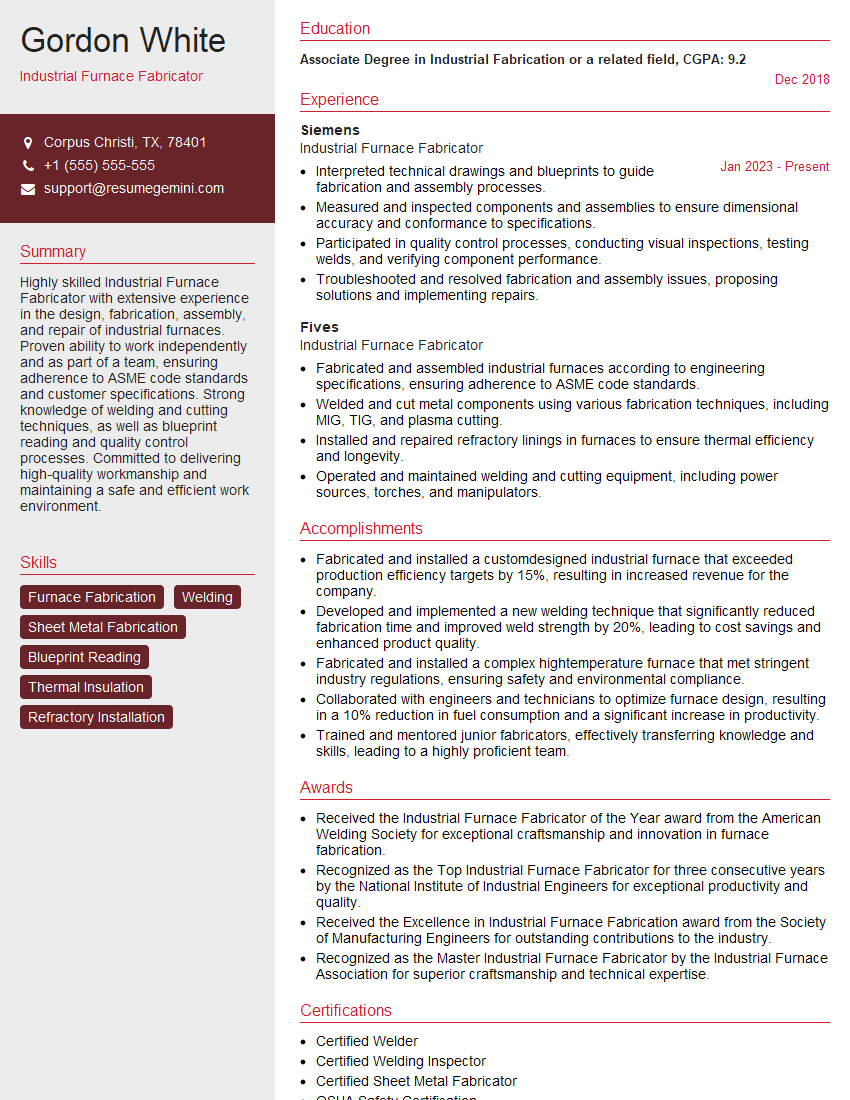

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Furnace Fabricator

1. What are the different types of industrial furnaces, and what are their applications?

- Box Furnaces: These furnaces are used for heat treating metals in a controlled atmosphere. They come in various sizes and can be used for a variety of applications.

- Pit Furnaces: These furnaces are used to heat treat large metal parts. They are typically cylindrical in shape and have a deep pit in which the parts are placed.

- Rotary Furnaces: These furnaces are used to heat treat small metal parts. They rotate continuously, which helps to ensure uniform heating.

- Tunnel Furnaces: These furnaces are used to heat treat large metal sheets. They have a long, narrow chamber through which the sheets are conveyed.

2. What are the key considerations when designing and fabricating an industrial furnace?

Factors Affecting Furnace Design:

- Purpose and Application: The specific heat treatment process and the materials being treated determine the design requirements.

- Temperature Range and Uniformity: The furnace must be able to achieve and maintain the desired temperature range consistently throughout the chamber.

- Atmosphere Control: Furnaces may operate in various atmospheres, such as air, inert gases, or vacuum, which influences the design of the heating elements and seals.

Fabrication Considerations:

- Material Selection: Furnaces are typically constructed from high-temperature alloys that can withstand the operating conditions.

- Welding and Assembly: Proper welding techniques and quality control are crucial to ensure the furnace’s structural integrity and longevity.

- Insulation and Refractory Lining: Insulation minimizes heat loss and maintains temperature uniformity, while refractory linings protect the furnace chamber from degradation.

3. What are the different types of heating elements used in industrial furnaces, and what are their advantages and disadvantages?

- Gas Burners: Advantages: High efficiency, low operating costs. Disadvantages: Emissions, temperature limitations.

- Electric Resistance Elements: Advantages: Precise temperature control, clean operation. Disadvantages: Higher energy consumption, limited temperature range.

- Induction Heating: Advantages: Rapid heating, energy efficiency. Disadvantages: Requires conductive materials, complex equipment.

- Microwave Heating: Advantages: Uniform heating, fast response. Disadvantages: Limited to dielectric materials, high equipment cost.

4. What are the different types of temperature control systems used in industrial furnaces, and how do they work?

- Manual Control: The operator manually adjusts the heat input based on experience and observation.

- Single-Loop Control: Uses a temperature sensor and controller to maintain a set temperature.

- Multi-Loop Control: Uses multiple temperature sensors and controllers to achieve precise temperature profiles.

- Programmable Logic Controllers (PLCs): Advanced control systems that allow for complex temperature profiles and process automation.

5. What are the safety considerations when working with industrial furnaces?

- High Temperatures: Wear appropriate protective clothing and equipment.

- Hazardous Gases: Ensure proper ventilation and use respiratory protection if necessary.

- Electrical Hazards: Follow proper electrical safety protocols.

- Fire Hazards: Have fire extinguishers readily available and follow emergency procedures.

- Moving Parts: Be aware of potential pinch points and other hazards.

6. What are the maintenance procedures for industrial furnaces?

- Regular Inspections: Check for wear and tear, loose connections, and any potential issues.

- Cleaning and Lubrication: Clean heating elements, burners, and other components to ensure optimal performance.

- Calibration of Sensors: Calibrate temperature sensors and controllers regularly for accurate temperature readings.

- Repairs and Replacements: Replace worn or damaged components promptly to prevent breakdowns.

- Documentation: Keep detailed maintenance records for future reference and troubleshooting.

7. What are the different types of fuel used in industrial furnaces, and what are their advantages and disadvantages?

- Natural Gas: Advantages: Clean-burning, widely available. Disadvantages: Price fluctuations, potential supply disruptions.

- Propane: Advantages: Portable, high heat output. Disadvantages: More expensive than natural gas, storage limitations.

- Oil: Advantages: High energy density, suitable for high-temperature applications. Disadvantages: Emissions, storage requirements.

- Electricity: Advantages: Clean operation, precise temperature control. Disadvantages: Higher operating costs, potential power outages.

8. What are the different types of refractory materials used in industrial furnaces, and what are their properties?

- Ceramic Fiber: Lightweight, excellent insulation, low thermal conductivity.

- Firebricks: High-temperature resistance, durable, but less insulating than ceramic fiber.

- Castable Refractories: Can be poured and shaped, provides monolithic linings, but may have lower strength.

- Insulating Bricks: Lightweight, good insulation, but lower temperature resistance compared to firebricks.

9. What are the different types of heat treatment processes performed in industrial furnaces?

- Annealing: Heat treatment process to soften metals and improve ductility.

- Hardening: Heat treatment process to increase the hardness and strength of metals.

- Tempering: Heat treatment process to reduce brittleness and improve toughness.

- Normalizing: Heat treatment process to refine grain structure and improve mechanical properties.

10. What are the latest trends and advancements in industrial furnace technology?

- Energy Efficiency: Improved insulation and heat recovery systems to reduce energy consumption.

- Automation and Control: Advanced control systems for precise temperature control and process optimization.

- Additive Manufacturing: 3D printing techniques to create complex furnace components with higher precision.

- Environmental Regulations: Development of clean-burning technologies to meet emission standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Furnace Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Furnace Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Furnace Fabricators are responsible for the fabrication, installation, and maintenance of industrial furnaces. They work closely with engineers and other professionals to ensure that furnaces are built to specifications and operate safely and efficiently. Key job responsibilities include:

1. Fabrication

Fabricate furnace components, such as shells, tubes, and burners, using a variety of materials, including steel, stainless steel, and refractory materials.

- Operate fabrication equipment, such as welding machines, cutting torches, and bending machines.

- Inspect fabricated components to ensure that they meet specifications.

2. Installation

Install furnaces according to blueprints and specifications.

- Connect furnaces to utilities, such as gas, electricity, and water.

- Start-up furnaces and ensure that they are operating properly.

3. Maintenance

Perform preventive maintenance on furnaces to ensure that they are operating safely and efficiently.

- Troubleshoot and repair furnaces when they break down.

- Keep records of maintenance activities.

4. Safety

Follow all safety procedures and regulations.

- Wear appropriate personal protective equipment (PPE).

- Work in a safe and orderly manner.

Interview Tips

Preparing for an interview for an Industrial Furnace Fabricator position is essential to showcase your skills and experience. Here are some tips to help you ace the interview:

1. Research the company and the position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and business goals. You should also be familiar with the specific duties and responsibilities of the furnace fabricator position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a furnace fabricator. Be prepared to discuss your experience in detail, including your role in the fabrication, installation, and maintenance of furnaces. You should also be able to demonstrate your skills in areas such as welding, cutting, and bending.

4. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic and positive about their work. Be sure to convey your passion for furnace fabrication and your desire to work for the company. A positive attitude can go a long way in making a good impression on the interviewer.

5. Follow up after the interview

After the interview, be sure to follow up with the interviewer by sending a thank-you note. This is a simple way to show your appreciation for their time and consideration and to reiterate your interest in the position.

Next Step:

Now that you’re armed with the knowledge of Industrial Furnace Fabricator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Industrial Furnace Fabricator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini