Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Octave Board Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

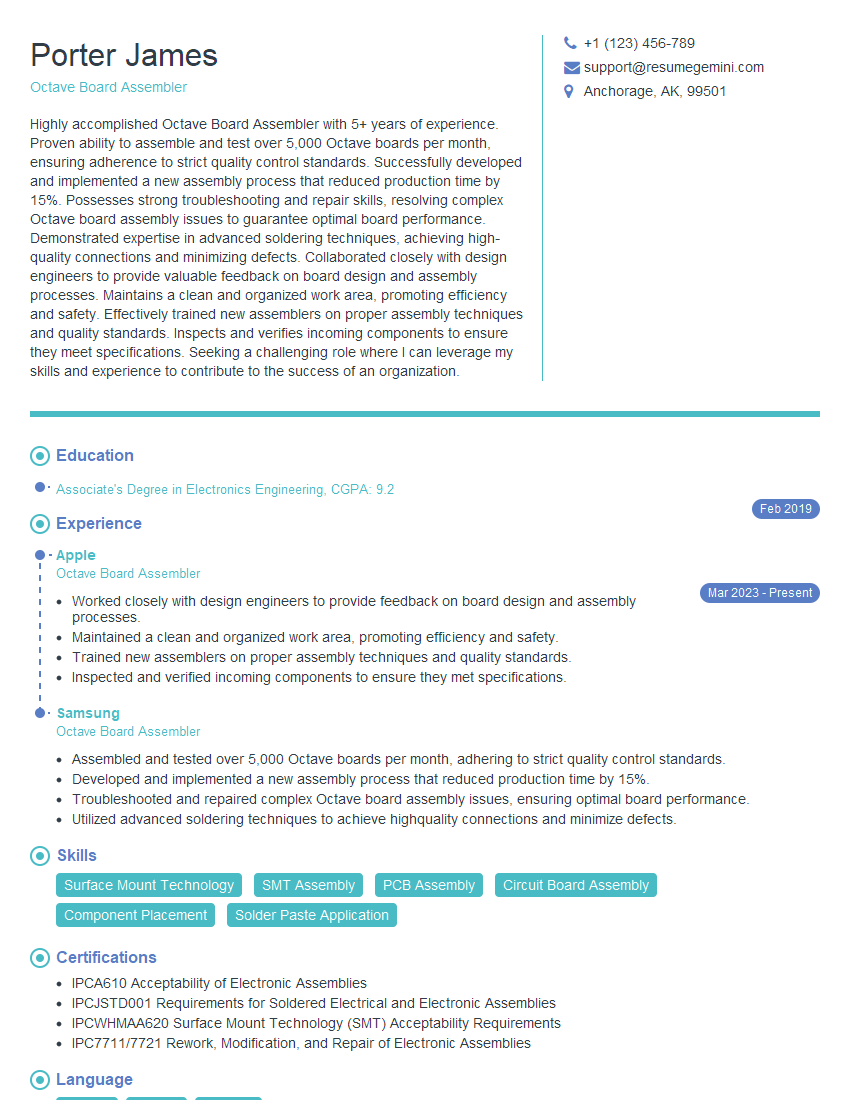

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Octave Board Assembler

1. What are the key steps involved in assembling an Octave board?

- Gather necessary components and materials

- Prepare the work area and tools

- Assemble the board by following the schematic diagram

- Solder the components onto the board

- Test the assembled board

2. What soldering techniques are used in Octave board assembly?

Surface Mount Technology (SMT)

- Reflow soldering

- Wave soldering

Through-Hole Technology (THT)

- Hand soldering

- Wave soldering

3. What are the common defects that can occur during Octave board assembly and how can they be prevented?

- Solder bridging: Use proper soldering techniques and ensure adequate spacing between components

- Solder voids: Use appropriate solder paste and reflow oven settings

- Tombstoning: Ensure proper component placement and use a solder paste with the right viscosity

- Misaligned components: Use a pick-and-place machine for precise component placement

- Electrostatic discharge (ESD) damage: Implement proper ESD protection measures

4. What quality control measures are essential in Octave board assembly?

- Visual inspection

- Electrical testing

- Functional testing

- Environmental stress screening

- Documentation and record-keeping

5. What are the safety precautions that must be followed during Octave board assembly?

- Wear appropriate safety gear, including gloves, safety glasses, and an anti-static wrist strap

- Use soldering equipment properly and handle materials with care

- Follow ESD protection procedures

- Maintain a clean and organized work area

- Be aware of potential hazards and know emergency procedures

6. What are the different types of components used in Octave boards and how are they identified?

- Resistors: Color-coded bands

- Capacitors: Value and tolerance markings

- Inductors: Color-coded dots or stripes

- Diodes: Orientation indicated by a cathode band

- Transistors: Base, collector, and emitter terminals identified

- Integrated circuits (ICs): Pin numbers or markings

7. What tools and equipment are necessary for Octave board assembly?

- Soldering iron or wave soldering machine

- Solder paste or solder wire

- Tweezers

- Magnifying glass or microscope

- Multimeter

- Function generator

- Oscilloscope

8. What materials are used in Octave board assembly and what are their properties?

- Printed circuit boards (PCBs): Non-conductive material with copper traces

- Solder: Conductive alloy used to connect components

- Components: Made of various materials, including resistors, capacitors, and transistors

- Flux: Cleaning agent used to remove oxides and improve solderability

- Conformal coating: Protective layer applied to protect the board from environmental factors

9. What are the challenges and best practices in designing and assembling high-frequency Octave boards?

- Challenges: Signal integrity, noise reduction, impedance matching

- Best practices: Use high-frequency materials, minimize trace lengths, control impedance, and proper grounding

10. What are the latest trends and advancements in Octave board assembly technology?

- Miniaturization and high-density assembly

- Flexible and stretchable electronics

- Additive manufacturing (3D printing) for prototyping and production

- Automated assembly and quality control

- Artificial intelligence (AI) for process optimization

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Octave Board Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Octave Board Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Octave Board Assembler is accountable for assembling and testing Octave boards, ensuring they meet specifications and quality standards. Key responsibilities include:

1. Assembly and Inspection

Assemble Octave boards by following engineering drawings and assembly instructions.

- Inspect components for defects before assembly.

- Use proper tools and techniques to assemble boards, ensuring correct component placement and alignment.

2. Testing and Troubleshooting

Perform electrical tests on assembled boards to verify functionality and identify any defects.

- Troubleshoot and rectify any issues or defects found during testing.

- Document testing results and report any discrepancies to supervisors.

3. Quality Control

Maintain the highest standards of quality control throughout the assembly process.

- Adhere to established quality standards and procedures.

- Identify and eliminate potential sources of errors or defects.

- Suggest improvements to assembly processes and procedures to enhance quality and efficiency.

4. Maintenance and Inventory

Maintain and organize assembly equipment and tools.

- Monitor inventory levels and ensure the availability of necessary components.

- Keep work areas clean, organized, and free of hazards.

Interview Tips

To ace an interview for an Octave Board Assembler position, consider the following tips:

1. Research the Company and Position

Thoroughly research the company and the specific Octave Board Assembler position to demonstrate your interest and understanding of the role.

- Review the company website, social media pages, and industry news to learn about their products, services, and culture.

- Study the job description carefully and identify the key responsibilities, skills, and qualifications required for the position.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements.

- Quantify your achievements and provide specific examples of your work experience.

- Use action verbs and industry-specific terminology to demonstrate your technical abilities.

3. Prepare for Technical Questions

Anticipate and prepare for technical questions related to board assembly and testing.

- Review basic electronics concepts, such as voltage, current, resistance, and Ohm’s law.

- Practice troubleshooting common assembly and testing issues.

- Be prepared to discuss your experience with specific assembly and testing equipment.

4. Demonstrate Your Quality Focus

Stress your commitment to quality control and attention to detail.

- Explain your understanding of quality standards and procedures.

- Provide examples of how you have identified and eliminated errors or defects in previous roles.

- Discuss your suggestions for improving assembly processes and procedures.

5. Show Enthusiasm and Motivation

Convey your enthusiasm for the role and your motivation to contribute to the company’s success.

- Express your interest in the company’s products or services.

- Share your passion for electronics assembly and testing.

- Explain your eagerness to learn and grow in the field.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Octave Board Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!