Are you gearing up for an interview for a Printed Circuit Boards Lamination Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Printed Circuit Boards Lamination Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

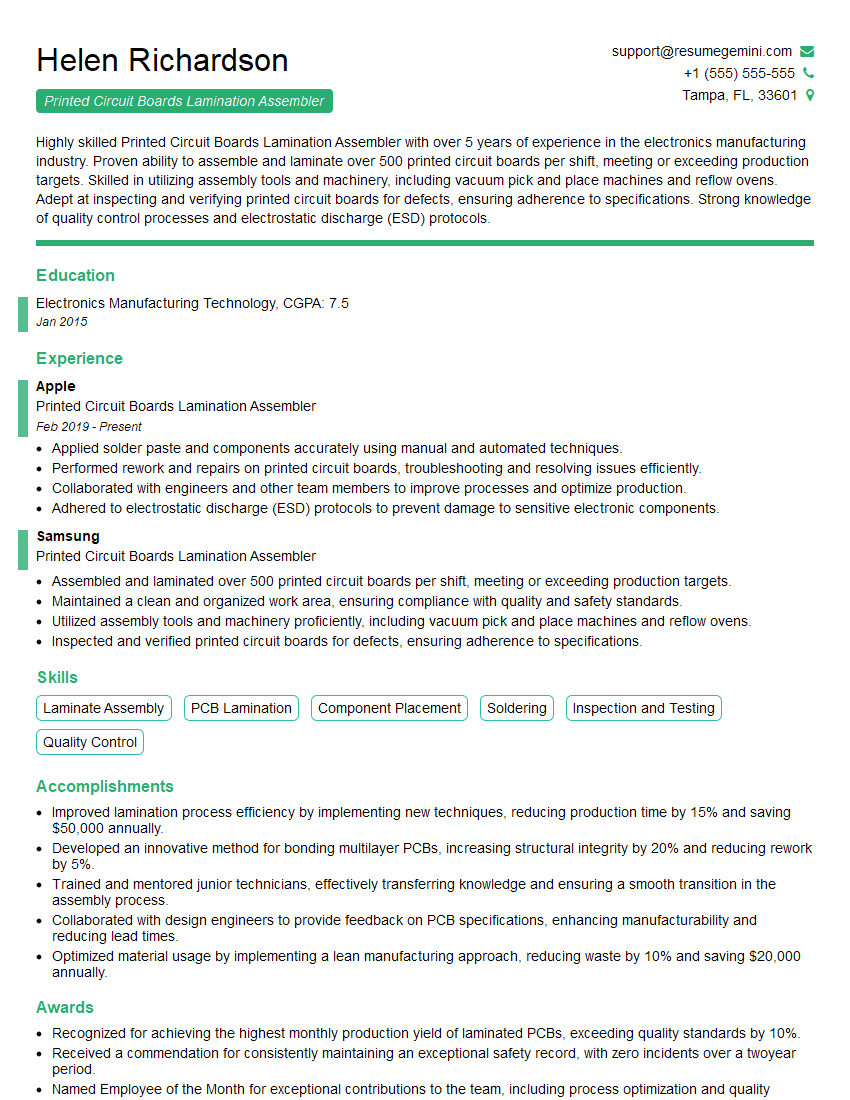

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Boards Lamination Assembler

1. How would you go about troubleshooting a PCB lamination issue where the copper is peeling off the substrate?

- Inspect the substrate for any contamination or damage.

- Check the lamination parameters, such as temperature, pressure, and time, to ensure they are within the specified range.

- Examine the copper foil for any defects or imperfections.

- Verify that the adhesive used for lamination is suitable for the substrate and copper foil.

- Consider the possibility of electrostatic discharge (ESD) damage.

2. What are the key factors to consider when selecting a solder mask for a PCB?

Material properties

- Adhesion to the copper and substrate

- Resistance to chemicals and solvents

- Thermal stability

- Electrical insulation properties

Processability

- Screen printing or photoresist application

- Curing requirements

- Compatibility with other PCB materials

Design considerations

- Feature size and spacing

- Solder mask thickness

- Solder mask color

3. How do you ensure the alignment of multiple layers during the lamination process?

- Use precision registration marks on the inner layers and core.

- Employ alignment pins or fixtures.

- Utilize laser alignment systems.

- Laminate in stages, with intermediate inspections.

- Control the temperature and pressure during lamination.

4. What are the potential causes of voids in the laminated PCB?

- Entrapped air or moisture during lamination.

- Insufficient pressure or temperature during lamination.

- Delamination due to poor adhesion between layers.

- Voids in the prepreg material.

- Contamination or defects in the substrate or copper foil.

5. How do you inspect a laminated PCB for defects?

- Visual inspection for any physical defects, such as delamination, cracks, or scratches.

- Electrical testing to verify continuity and insulation resistance.

- X-ray inspection to detect internal defects, such as voids or inclusions.

- Microscopic examination to analyze the quality of lamination and identify any potential issues.

6. What are the different types of adhesives used in PCB lamination?

- Epoxy adhesives: High strength and thermal stability.

- Phenolic adhesives: Low cost and good electrical insulation.

- Polyimide adhesives: High-temperature resistance and flexibility.

- Acrylic adhesives: Good adhesion to a wide range of materials.

- UV-curable adhesives: Fast curing and low-temperature processing.

7. What are the safety precautions that should be taken when working with PCB lamination materials?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Handle chemicals with care and follow the manufacturer’s safety instructions.

- Ensure proper ventilation to avoid exposure to fumes or gases.

- Store materials in a safe and controlled environment.

- Be aware of the potential hazards of high temperatures and electrical equipment.

8. How do you maintain and calibrate the equipment used in PCB lamination?

- Follow the manufacturer’s recommended maintenance schedule.

- Regularly clean and inspect equipment.

- Calibrate equipment using certified standards.

- Keep a record of maintenance and calibration activities.

- Train operators on proper equipment usage and maintenance.

9. What are the key quality control measures in PCB lamination?

- Incoming material inspection.

- Process control during lamination.

- Post-lamination inspection.

- Electrical testing.

- Environmental testing.

10. How do you improve the efficiency and yield of the PCB lamination process?

- Optimize lamination parameters, such as temperature, pressure, and time.

- Use high-quality materials and equipment.

- Implement automated processes.

- Reduce waste and rework.

- Continuously improve processes through data analysis and feedback.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Boards Lamination Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Boards Lamination Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Printed Circuit Boards (PCB) Lamination Assemblers are skilled professionals who play a crucial role in the electronics manufacturing industry. They are responsible for assembling and laminating PCBs, ensuring that they meet the required specifications and quality standards.

1. PCB Assembly

Assembling PCBs accurately and efficiently, ensuring proper alignment and placement of components.

2. Lamination Process

Laminating PCBs using appropriate materials and equipment, adhering to established procedures for bonding and curing.

3. Quality Control

Inspecting PCBs for defects, ensuring compliance with design specifications and quality standards.

4. Equipment Maintenance

Maintaining and calibrating lamination equipment, ensuring optimal performance and accuracy.

Interview Tips

Preparing for a Printed Circuit Boards Lamination Assembler interview requires a thorough understanding of the role and the industry. Here are a few tips to help candidates ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s background, products, and industry standing. Research specific details about the Lamination Assembler role to understand its responsibilities, skills, and experience requirements.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in PCB assembly and lamination processes. Showcase your experience working with different types of PCBs and materials. Quantify your accomplishments using specific metrics to demonstrate your impact.

3. Prepare for Technical Questions

Expect questions about PCB assembly techniques, laminating materials, and quality control procedures. Be prepared to discuss your understanding of these topics and demonstrate your ability to apply them in a practical setting.

4. Showcase Attention to Detail

This role requires meticulous attention to detail. Highlight your ability to identify and correct errors in PCB assembly and lamination, ensuring the highest quality of output.

5. Practice Your Communication Skills

Effective communication is essential for coordinating with colleagues and understanding instructions. Practice articulating your ideas clearly and concisely, demonstrating your ability to collaborate effectively.

6. Prepare Questions for the Interviewer

Ask thoughtful questions about the company, the role, or the industry. This shows your engagement and interest in the position and the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Printed Circuit Boards Lamination Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!