Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the X Ray Electronics Wiring Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a X Ray Electronics Wiring Technician so you can tailor your answers to impress potential employers.

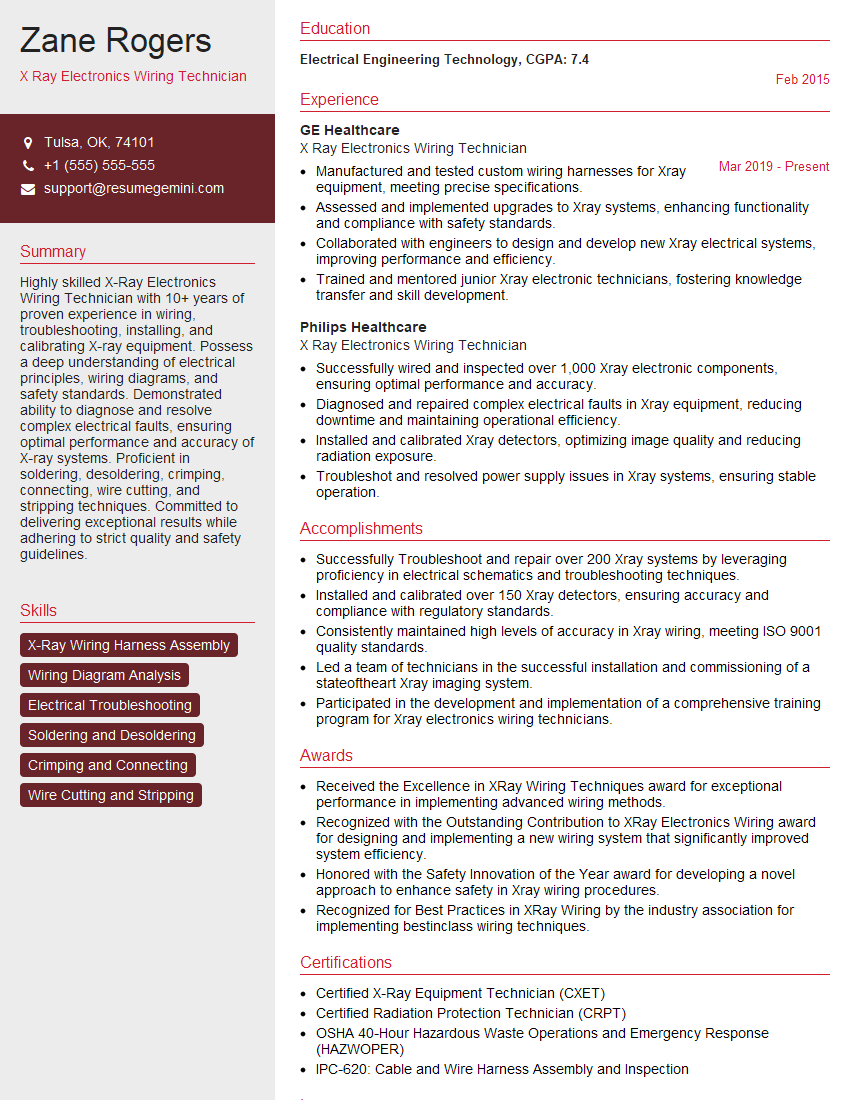

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For X Ray Electronics Wiring Technician

1. What are the different types of X-ray machines and their applications?

There are various types of X-ray machines, each designed for specific applications. Here are a few common types:

- Fixed X-ray machines: Mounted on a stand or ceiling, these machines are used in hospitals, clinics, and dental offices for general radiography.

- Mobile X-ray machines: Portable and lightweight, these machines can be moved around to take X-rays in different locations, such as patient rooms or operating theaters.

- C-arm X-ray machines: Used in surgical and interventional procedures, these machines provide real-time fluoroscopic imaging, allowing surgeons to visualize the anatomy and guide their actions.

- Computed Tomography (CT) scanners: Utilize multiple X-ray beams to create cross-sectional images of the body, providing detailed anatomical information.

2. Describe the process of X-ray wire harnessing.

Technical Specifications

- Understanding the electrical schematic and wire list

- Selecting appropriate wires based on gauge, insulation, and shielding

- Cutting wires to precise lengths and stripping insulation

- Crimping terminals and connectors to ensure secure connections

Quality Control

- Inspecting wires for damage and correct specifications

- Testing connections for continuity and insulation resistance

- Ensuring proper routing and bundling of wires

- Labeling and documenting the harness for traceability

3. What are the common challenges faced during X-ray wiring harness assembly?

During X-ray wiring harness assembly, several challenges may arise:

- Space constraints: Limited space within X-ray systems requires careful planning and routing of wires.

- High voltage and current: X-ray systems operate at high voltages and currents, necessitating the use of specialized wires and insulation.

- Radiation exposure: Working with X-ray equipment requires adherence to strict safety protocols to minimize radiation exposure.

- Precision and accuracy: Wiring harnesses must be assembled with precision to ensure proper functionality and safety.

4. How do you ensure the accuracy and reliability of your wiring harnesses?

To ensure the accuracy and reliability of our wiring harnesses, we implement the following measures:

- Thorough documentation: Maintaining detailed technical documentation throughout the process

- Quality control inspections: Conducting regular inspections at various stages of assembly

- Testing and verification: Performing electrical testing to verify continuity, insulation resistance, and overall functionality

- Use of high-quality materials: Utilizing wires, insulation, and connectors that meet industry standards

- Continuous improvement: Regularly reviewing and optimizing our processes based on feedback and industry best practices

5. What is the importance of proper grounding in X-ray wiring?

Proper grounding in X-ray wiring is crucial for several reasons:

- Safety: Grounding provides a path for fault currents to flow, preventing electrical shocks and damage to equipment.

- Image quality: Proper grounding minimizes electrical noise and interference, resulting in clearer and more accurate X-ray images.

- Equipment protection: Grounding helps protect X-ray equipment from voltage surges and transients.

- Compliance: Adhering to grounding standards is essential for meeting regulatory requirements and ensuring the safe operation of X-ray systems.

6. Explain the different types of testing methods used to validate X-ray wiring harnesses.

To validate the performance and reliability of X-ray wiring harnesses, various testing methods are employed:

- Electrical testing: This includes continuity testing to verify proper connections, insulation resistance testing to ensure adequate insulation, and high-voltage testing to check for dielectric strength.

- Mechanical testing: This involves testing the harness for its ability to withstand vibration, shock, and temperature extremes.

- Environmental testing: This includes exposure to humidity, salt spray, and other environmental conditions to assess the harness’s durability.

- Functional testing: This involves connecting the harness to an X-ray system and evaluating its performance under actual operating conditions.

7. How do you stay updated with the latest advancements in X-ray wiring technologies?

To stay updated with the latest advancements in X-ray wiring technologies, I actively engage in the following practices:

- Industry conferences and exhibitions: Attending industry events provides valuable opportunities to learn about new technologies and trends.

- Technical publications and journals: Reading industry publications and scientific journals helps me stay abreast of research and developments.

- Online webinars and training: Participating in online webinars and training programs offered by manufacturers and experts keeps me informed about emerging technologies.

- Networking with professionals: Connecting with other professionals in the field allows me to exchange knowledge and learn from their experiences.

8. What are the safety precautions that you follow when working with X-ray wiring systems?

When working with X-ray wiring systems, I strictly adhere to the following safety precautions:

- Radiation safety: Always wearing appropriate personal protective equipment (PPE), such as a lead apron and gloves, and following radiation safety protocols.

- Electrical safety: Ensuring that the system is properly grounded and isolated before performing any work, and using appropriate tools and techniques to prevent electrical shocks.

- Mechanical safety: Taking precautions to avoid physical hazards, such as sharp edges or moving parts, and using ergonomic principles to prevent injuries.

- Chemical safety: Handling and disposing of chemicals, such as solvents or cleaning agents, in a safe and environmentally responsible manner.

9. Describe your experience in troubleshooting and repairing X-ray wiring harnesses.

In my previous role, I was responsible for troubleshooting and repairing X-ray wiring harnesses. Here are some examples of my experiences:

- Identifying and repairing loose connections: Using a multimeter and visual inspection, I successfully identified and repaired loose connections that caused intermittent operation.

- Replacing damaged wires: I replaced damaged wires due to wear and tear or accidental damage, ensuring the integrity of the harness.

- Resoldering broken solder joints: I repaired broken solder joints using proper soldering techniques and materials.

- Testing and validating repairs: After completing repairs, I performed rigorous testing to ensure the harness met performance specifications.

10. How do you prioritize multiple tasks and manage your time effectively when working on X-ray wiring projects?

When working on X-ray wiring projects, I prioritize tasks and manage my time effectively using the following techniques:

- Task prioritization: I prioritize tasks based on urgency, importance, and dependencies, using a system such as the Eisenhower Matrix.

- Time management: I break down large tasks into smaller, manageable chunks and allocate realistic timeframes for each.

- Scheduling and planning: I create a detailed schedule and plan to allocate time efficiently and avoid conflicts.

- Delegation: When necessary, I delegate tasks to colleagues to optimize workflow and meet deadlines.

- Communication: I regularly communicate with my team and stakeholders to ensure alignment on priorities and timelines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for X Ray Electronics Wiring Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the X Ray Electronics Wiring Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

X Ray Electronics Wiring Technicians play a critical role in maintaining and repairing X-ray equipment used in medical and industrial settings. Their responsibilities encompass:

1. Wiring and Assembly

– Installing and connecting electrical wires, cables, and components within X-ray machines

– Ensuring proper electrical connections and insulation to maintain optimal performance and safety

2. Troubleshooting and Repair

– Diagnosing electrical faults, malfunctions, and performance issues in X-ray equipment

– Repairing and replacing damaged or faulty components, including wiring, connectors, and circuit boards

3. Maintenance and Inspection

– Conducting regular inspections and preventive maintenance to ensure equipment reliability and longevity

– Monitoring equipment performance, identifying potential problems, and taking corrective actions

4. Compliance and Safety

– Adhering to industry standards, regulations, and safety protocols while working with X-ray equipment

– Ensuring electrical safety, preventing electrical hazards, and minimizing radiation exposure

Interview Tips

Preparing thoroughly for an interview can significantly enhance your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

– Gather information about the company’s industry, mission, and values

– Study the job description carefully to identify the specific skills, experience, and qualifications required

2. Practice Your Answers

– Prepare responses to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

– Rehearse your answers aloud to enhance your confidence and delivery

3. Highlight Relevant Skills and Experience

– Showcase your technical proficiency in electrical wiring, troubleshooting, and X-ray equipment

– Emphasize your attention to detail, problem-solving abilities, and commitment to safety

4. Ask Thoughtful Questions

– Prepare insightful questions to demonstrate your interest in the role and the company

– Asking questions also shows that you are engaged and eager to learn more

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the X Ray Electronics Wiring Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.