Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electric Motor and Generator Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

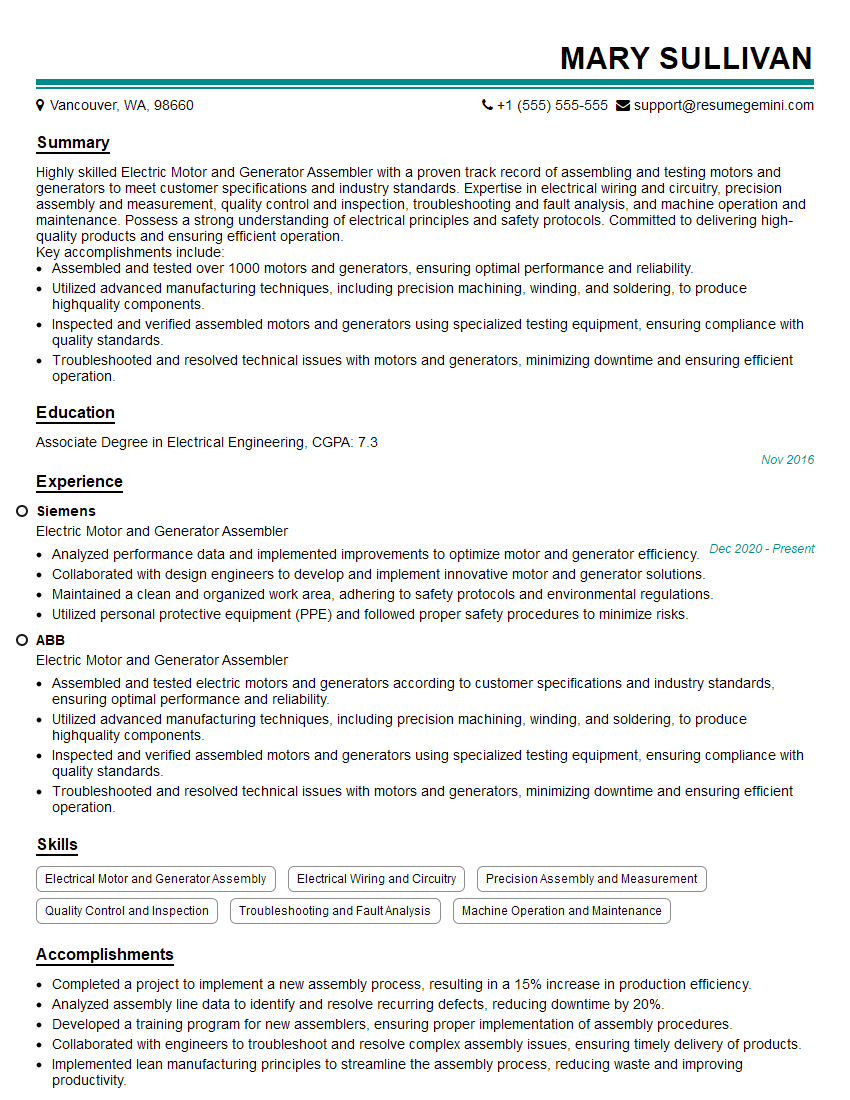

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Motor and Generator Assembler

1. Explain the process of assembling an electric motor.

The process of assembling an electric motor involves several key steps:

- Winding the stator coils: The stator coils are wound around a laminated steel core, creating the electromagnetic field that will interact with the rotor.

- Inserting the rotor into the stator: The rotor, consisting of a laminated steel core and copper bars, is then inserted into the stator and centered.

- Connecting the coils to the terminals: The stator coils are then connected to the motor’s terminals, providing the electrical input.

- Installing the end plates and bearings: End plates are attached to each end of the motor to hold the rotor in place and provide support for the bearings.

- Testing and quality control: The assembled motor undergoes thorough testing to ensure its electrical and mechanical integrity, meeting industry standards.

2. Describe the different types of electric generators and their applications.

AC Generators:

- Synchronous Generators: Used for large-scale power generation in power plants and industries, providing stable voltage and frequency.

- Induction Generators: Commonly used in wind turbines and hydro generators, where speed and frequency vary.

DC Generators:

- Brushed DC Generators: Utilize mechanical brushes to collect current, suitable for small-scale applications.

- Brushless DC Generators: Employ electronic commutation, offering higher efficiency and longer lifespan.

3. How do you ensure the proper alignment of components during motor and generator assembly?

Ensuring proper alignment is crucial for optimal performance and longevity of motors and generators:

- Alignment of rotor and stator: Using precision gauges and measuring tools to align the rotor and stator, minimizing eccentricity and vibration.

- Alignment of bearings: Calibrated laser alignment systems or dial indicators are utilized to align bearings accurately, reducing friction and wear.

- Shaft alignment: For multi-stage motors or generators, shaft alignment is critical for smooth operation and power transmission.

4. What testing procedures do you perform on assembled motors and generators before they are ready for shipment?

To ensure reliability and compliance, several tests are conducted:

- Electrical testing: Insulation resistance, dielectric strength, and voltage withstand tests are performed to verify electrical integrity.

- Mechanical testing: Runout tests check for alignment and balance, while vibration testing ensures smooth operation.

- Performance testing: Load testing evaluates motor and generator performance, including efficiency, power output, and torque.

5. Can you describe the importance of balancing rotors in electric motors and generators?

Balancing rotors is essential for reducing vibration and extending the lifespan of motors and generators:

- Vibration Reduction: Unbalanced rotors cause excessive vibration, which can damage bearings, housings, and other components.

- Extended Lifespan: Balanced rotors operate smoothly, reducing stress on components and increasing their longevity.

- Improved Performance: Balanced rotors enable smoother and more efficient operation, resulting in increased performance and reliability.

6. What safety precautions should be taken when handling high-voltage motors and generators?

Working with high-voltage equipment requires strict safety precautions:

- Electrical Isolation: Ensure proper electrical isolation of tools, equipment, and personnel.

- Grounding: Ground all equipment and components to prevent electrical shocks.

- Personal Protective Equipment: Wear appropriate personal protective equipment (PPE), including insulated gloves, eye protection, and flame-resistant clothing.

- Training and Authorization: Only trained and authorized individuals should handle high-voltage equipment.

7. What are the typical materials used in the construction of electric motors and generators?

- Laminated Steel: Used for stator and rotor cores to minimize eddy current losses.

- Copper: Employed for windings due to its high conductivity and current-carrying capacity.

- Magnets: Permanent or electromagnets generate the magnetic field necessary for motor and generator operation.

- Bearings: Support the rotating components and reduce friction.

- Insulating Materials: Protect components from electrical shorts and provide dielectric strength.

8. Can you troubleshoot a motor that is overheating?

Troubleshooting a motor overheating issue involves several steps:

- Check Ventilation: Ensure proper ventilation around the motor, as inadequate airflow can cause overheating.

- Inspect Bearings: Worn or damaged bearings can increase friction and generate excessive heat.

- Electrical Testing: Measure current draw and winding resistance to identify potential electrical faults.

- Overloading: Verify that the motor is not overloaded, as operating beyond its capacity can lead to overheating.

- Environmental Conditions: Consider environmental factors such as ambient temperature and humidity.

9. What are the advantages of using variable frequency drives (VFDs) with electric motors?

- Speed Control: VFDs allow precise control of motor speed, optimizing performance for different applications.

- Energy Savings: By adjusting motor speed according to load requirements, VFDs reduce energy consumption.

- Reduced Maintenance: VFDs eliminate the need for mechanical speed control devices, reducing maintenance costs.

- Improved Process Control: VFDs enable precise control of motor speed, which is critical for many industrial processes.

10. How do you stay updated on the latest advancements in electric motor and generator technology?

- Industry Events and Conferences: Attend industry events and conferences to network with experts and learn about new technologies.

- Trade Publications and Journals: Subscribe to industry publications and journals to stay informed on the latest developments.

- Technical Training and Workshops: Participate in technical training and workshops to enhance knowledge and skills.

- Online Resources and Forums: Utilize online resources, forums, and discussion groups to engage with professionals and stay updated on industry trends.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Motor and Generator Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Motor and Generator Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Motor and Generator Assemblers are responsible for assembling and testing electric motors and generators. They work in a variety of settings, including manufacturing plants, repair shops, and research laboratories.

1. Assemble electric motors and generators

Assemblers follow blueprints and work orders to assemble electric motors and generators. They use hand tools and power tools to connect components, such as stators, rotors, and bearings. They also install electrical wiring and connect the motor or generator to a power source.

- Follow blueprints and work orders to assemble electric motors and generators

- Use hand tools and power tools to connect components, such as stators, rotors, and bearings

- Install electrical wiring and connect the motor or generator to a power source

2. Test electric motors and generators

Once the motor or generator is assembled, Assemblers test it to ensure that it meets specifications. They use a variety of testing equipment, such as multimeters and oscilloscopes, to check the motor’s or generator’s voltage, current, and power output. They also listen for any unusual noises or vibrations that could indicate a problem.

- Use a variety of testing equipment, such as multimeters and oscilloscopes, to check the motor’s or generator’s voltage, current, and power output

- Listen for any unusual noises or vibrations that could indicate a problem

3. Troubleshoot and repair electric motors and generators

If a motor or generator fails to meet specifications, Assemblers troubleshoot and repair it. They use their knowledge of electrical systems to identify the problem and make the necessary repairs. They may also replace damaged components or adjust the motor’s or generator’s settings.

- Use their knowledge of electrical systems to identify the problem and make the necessary repairs

- Replace damaged components or adjust the motor’s or generator’s settings

4. Maintain a clean and organized work area

Assemblers work in a variety of settings, but they all need to maintain a clean and organized work area. This helps to prevent accidents and ensures that the motors and generators they assemble are of high quality.

- Keep their work area clean and organized to prevent accidents

- Ensure that the motors and generators they assemble are of high quality

Interview Tips

If you’re preparing for an interview for an Electric Motor and Generator Assembler position, there are a few things you can do to increase your chances of success.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture and what they’re looking for in a candidate. You can find information about the company on their website, in industry publications, and on social media. You can also learn more about the position by reading the job description and talking to people who work in the industry.

- Visit the company’s website to learn about their culture and values

- Read industry publications to learn about the latest trends in the field

- Network with people who work in the industry to get insights into the position

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice answering these questions ahead of time so that you can deliver your answers confidently and concisely.

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Practice delivering your answers confidently and concisely

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as an Electric Motor and Generator Assembler. Be prepared to talk about your work history, your skills, and your qualifications. You can also bring a portfolio of your work to show the interviewer.

- Highlight your experience and skills as an Electric Motor and Generator Assembler

- Bring a portfolio of your work to show the interviewer

4. Be professional and enthusiastic

First impressions matter, so it’s important to be professional and enthusiastic during your interview. Dress appropriately, arrive on time, and be polite to everyone you meet. Also, be sure to maintain eye contact and speak clearly and confidently.

- Dress appropriately for the interview

- Arrive on time and be polite to everyone you meet

- Maintain eye contact and speak clearly and confidently

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Motor and Generator Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!