Feeling lost in a sea of interview questions? Landed that dream interview for Dyno Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dyno Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

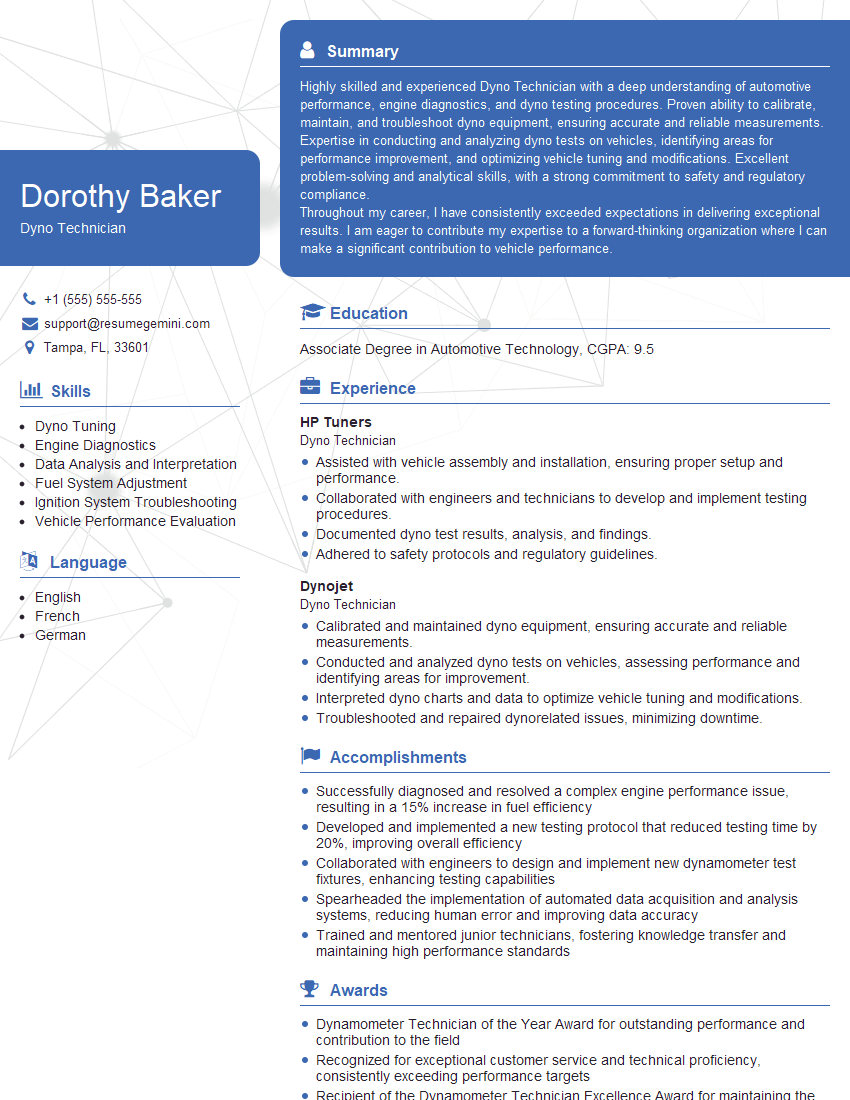

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dyno Technician

1. Explain the process of conducting a dyno test on a vehicle?

During a dyno test, the vehicle is placed on a dynamometer, which is a device that measures the vehicle’s power and torque. The vehicle is then run through a series of tests, which are designed to measure the vehicle’s performance at different speeds and loads. The data from the dyno test can be used to diagnose engine problems, optimize engine performance, and compare the performance of different vehicles.

- Secure the vehicle to the dynamometer.

- Connect the dynamometer to the vehicle’s drivetrain.

- Run the vehicle through a series of tests, which are designed to measure the vehicle’s performance at different speeds and loads.

- Analyze the data from the dyno test to diagnose engine problems, optimize engine performance, and compare the performance of different vehicles.

2. What are the different types of dynamometers and their applications?

Types of dynamometers

- Inertia dynamometer: This type of dynamometer uses a flywheel to simulate the load of the vehicle. Inertia dynamometers are relatively inexpensive and easy to operate, but they are not as accurate as other types of dynamometers.

- Load cell dynamometer: This type of dynamometer uses load cells to measure the force applied to the vehicle’s drivetrain. Load cell dynamometers are more accurate than inertia dynamometers, but they are also more expensive and complex to operate.

- Eddy current dynamometer: This type of dynamometer uses eddy currents to create a load on the vehicle’s drivetrain. Eddy current dynamometers are very accurate and can be used to simulate a wide range of loads.

Applications of dynamometers

- Engine development: Dynamometers are used to test and develop new engine designs.

- Vehicle performance testing: Dynamometers are used to measure the performance of vehicles, such as their power, torque, and fuel economy.

- Emissions testing: Dynamometers are used to measure the emissions produced by vehicles.

- Diagnostics: Dynamometers can be used to diagnose engine problems.

3. Describe the different types of sensors used in dyno testing and their functions?

- Speed sensor: This sensor measures the rotational speed of the vehicle’s wheels or engine.

- Torque sensor: This sensor measures the torque applied to the vehicle’s drivetrain.

- Power sensor: This sensor measures the power produced by the vehicle’s engine.

- Fuel consumption sensor: This sensor measures the amount of fuel consumed by the vehicle.

- Emissions sensors: These sensors measure the emissions produced by the vehicle.

4. Explain the importance of calibrating a dynamometer and the process involved in calibration?

Calibration is important to ensure that the dynamometer is providing accurate measurements. The calibration process involves using a known load to verify the accuracy of the dynamometer’s sensors. The dynamometer is then adjusted until the measurements are within the specified tolerances.

- Connect a known load to the dynamometer.

- Run the dynamometer and record the measurements.

- Compare the measurements to the known load.

- Adjust the dynamometer until the measurements are within the specified tolerances.

5. Describe the role of a dyno technician in ensuring the accuracy and reliability of dyno test results?

- Properly operate and maintain the dynamometer.

- Calibrate the dynamometer regularly.

- Follow the manufacturer’s instructions for conducting dyno tests.

- Analyze the data from dyno tests to identify any problems with the vehicle.

- Communicate the results of dyno tests to customers and other stakeholders.

6. What are the safety precautions that must be taken when operating a dynamometer?

- Always wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Never operate a dynamometer without proper training.

- Secure the vehicle to the dynamometer before starting the test.

- Keep a safe distance from the vehicle during the test.

- Be aware of the potential hazards of working around high-powered machinery.

7. Discuss the troubleshooting process for a dynamometer that is not providing accurate measurements?

- Check the calibration of the dynamometer.

- Inspect the dynamometer for any loose or damaged components.

- Check the electrical connections to the dynamometer.

- Contact the manufacturer of the dynamometer for assistance.

8. Explain the different types of dyno tests that can be performed on a vehicle?

- Steady-state testing: This type of test measures the performance of the vehicle at a constant speed and load.

- Transient testing: This type of test measures the performance of the vehicle during acceleration and deceleration.

- Emissions testing: This type of test measures the emissions produced by the vehicle.

- Diagnostic testing: This type of test is used to identify problems with the vehicle’s engine or drivetrain.

9. What are the benefits of using a dynamometer for vehicle testing?

- Dyno testing can be used to measure the performance of a vehicle in a controlled environment.

- Dyno testing can be used to identify problems with the vehicle’s engine or drivetrain.

- Dyno testing can be used to compare the performance of different vehicles.

- Dyno testing can be used to develop new engine designs.

10. What are the challenges of working as a dyno technician?

- Dyno technicians must have a strong understanding of the principles of engine operation and dynamometer operation.

- Dyno technicians must be able to work independently and as part of a team.

- Dyno technicians must be able to work in a demanding environment.

- Dyno technicians must be able to troubleshoot problems quickly and efficiently.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dyno Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dyno Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dyno technicians play a vital role in the automotive industry by ensuring the optimal performance of vehicles on a dynamometer. Their key responsibilities include:

1. Operating a Dynamometer

Dyno technicians are skilled in operating dynamometers, which are machines that simulate real-world driving conditions. They use this equipment to test and analyze the performance of engines and vehicles.

- Conducting various tests on engines and vehicles, such as acceleration, braking, and fuel efficiency tests.

- Collecting and analyzing data from the dynamometer to assess vehicle performance.

2. Troubleshooting and Repairing Vehicles

Dyno technicians troubleshoot and repair vehicles based on the data obtained from the dynamometer. They use a variety of diagnostic tools and techniques to identify and fix issues.

- Diagnosing vehicle problems by analyzing dynamometer data and other diagnostic tools.

- Repairing and replacing engine components, such as spark plugs, fuel injectors, and exhaust systems.

3. Calibrating and Maintaining Equipment

To ensure accurate and reliable test results, dyno technicians are responsible for calibrating and maintaining the dynamometer and other equipment.

- Calibrating the dynamometer using specialized tools and procedures.

- Performing routine maintenance and repairs on the dynamometer and other equipment.

4. Customer Service and Communication

Dyno technicians interact with customers, explaining test results and providing recommendations. They also work with other technicians and engineers to resolve technical issues.

- Providing clear and concise explanations of test results to customers.

- Effectively communicating with other technicians, engineers, and management.

Interview Tips

To ace an interview for a Dyno Technician position, candidates should consider the following tips:

1. Research the Company and Position

Research the automotive industry, the specific company you’re applying to, and the role of a Dyno Technician. This will help you understand the industry and the company’s expectations.

- Visit the company’s website to learn about their products, services, and culture.

- Read articles and industry publications to stay up-to-date on the latest trends and technologies.

2. Highlight Your Technical Skills and Experience

Emphasize your proficiency in operating dynamometers, troubleshooting and repairing vehicles, and calibrating equipment. Be prepared to discuss specific experiences and projects.

- Quantify your accomplishments using specific metrics, such as reducing vehicle repair time or improving fuel efficiency.

- Bring a portfolio or resume that showcases your technical skills and experience.

3. Demonstrate Your Problem-Solving Abilities

Employers value technicians who can diagnose and resolve technical issues efficiently. Highlight your problem-solving skills by providing examples of how you found and fixed complex problems.

- Describe a situation where you successfully diagnosed and repaired a vehicle using your technical expertise.

- Explain your approach to problem-solving and how you prioritize tasks.

4. Be Enthusiastic and Professional

Show that you are passionate about automotive technology and eager to learn and grow in the field. Maintain a positive and professional attitude throughout the interview.

- Express your enthusiasm for the industry and your desire to contribute to the company’s success.

- Dress appropriately, arrive on time, and be respectful of the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dyno Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.