Feeling lost in a sea of interview questions? Landed that dream interview for Metal Precision Machine Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metal Precision Machine Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

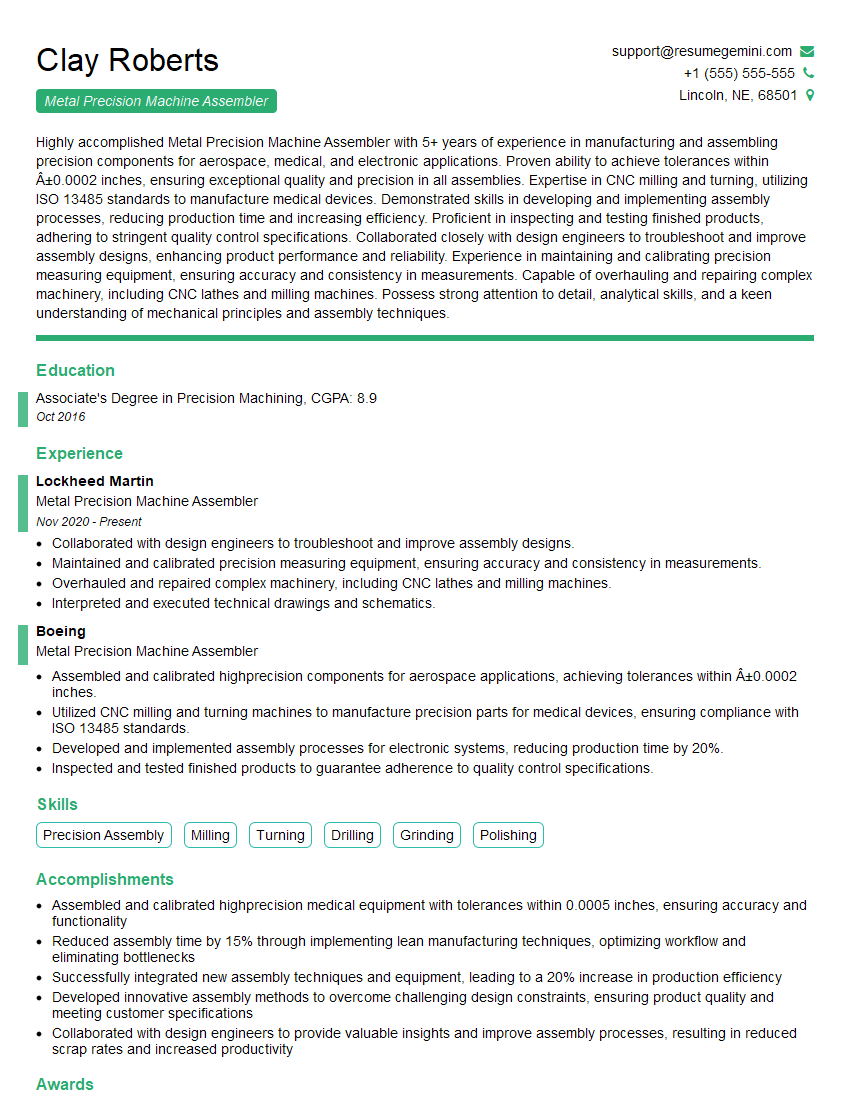

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Precision Machine Assembler

1. What is the difference between metal cutting and metal forming?

Metal cutting is a process that removes material from a workpiece to create a new shape. Metal forming is a process that changes the shape of a workpiece by applying force. In metal cutting, the workpiece is cut with a sharp tool, such as a saw, milling cutter, or drill bit. In metal forming, the workpiece is deformed by a die, press, or other forming tool.

2. What are the different types of metal cutting processes?

1: Abrasive cutting

- Abrasive cutting is a process that uses an abrasive material, such as a grinding wheel or saw blade, to cut through the workpiece.

- Abrasive cutting is often used to cut hard materials, such as metal, concrete, and stone.

Subheading 2: Shearing

- Shearing is a process that uses a sharp blade to cut through the workpiece.

- Shearing is often used to cut thin materials, such as sheet metal and plastic

3. What are the different types of metal forming processes?

There are many different types of metal forming processes, including:

- Rolling

- Forging

- Extrusion

- Drawing

- Bending

4. What is the purpose of annealing?

Annealing is a process that is used to soften metal by heating it to a high temperature and then slowly cooling it. Annealing is often used to make metal more ductile and easier to work with.

5. What is the difference between a lathe and a milling machine?

A lathe is a machine that is used to rotate a workpiece while a cutting tool is used to cut the workpiece. A milling machine is a machine that is used to cut metal by rotating a cutting tool against a stationary workpiece.

6. What is the difference between a drill press and a milling machine?

A drill press is a machine that is used to drill holes in metal. A milling machine is a machine that is used to cut metal by rotating a cutting tool against a stationary workpiece.

7. What is the difference between a surface grinder and a cylindrical grinder?

A surface grinder is a machine that is used to grind flat surfaces on metal. A cylindrical grinder is a machine that is used to grind cylindrical surfaces on metal.

8. What are the different types of cutting fluids?

There are many different types of cutting fluids, including:

- Soluble oils

- Semi-synthetic oils

- Synthetic oils

- Dry cutting fluids

9. What are the different types of machine tools?

There are many different types of machine tools, including:

- Lathes

- Milling machines

- Drill presses

- Surface grinders

- Cylindrical grinders

10. What are the different types of materials that can be machined?

There are many different types of materials that can be machined, including:

- Metals

- Plastics

- Wood

- Ceramics

- Composites

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Precision Machine Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Precision Machine Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Precision Machine Assemblers are responsible for assembling, adjusting, inspecting, and testing precision metal parts and assemblies, ensuring compliance with specifications and functional requirements.

1. Assembly and Fitting

Assembles and fits precision metal components according to blueprints and specifications.

- Reads and interprets blueprints and technical drawings to determine assembly sequence and requirements.

- Assembles components using hand tools, power tools, and specialized equipment.

2. Adjustment and Calibration

Adjusts and calibrates assembled parts to ensure proper fit, alignment, and tolerance requirements.

- Performs precision measurements using calipers, micrometers, and other measuring instruments.

- Makes fine adjustments to components to correct any deviations from specifications.

3. Inspection and Testing

Inspects and tests assembled parts and assemblies to verify quality and functionality.

- Conducts visual inspections to check for defects, corrosion, or contamination.

- Performs functional tests to ensure parts meet performance specifications.

4. Troubleshooting and Problem Solving

Troubleshoots and resolves problems encountered during assembly, adjustment, or testing.

- Identifies and analyzes assembly issues, such as misalignment, tolerance errors, or component failures.

- Develops and implements solutions to resolve problems and ensure optimal performance.

Interview Tips

Preparing for an interview for the position of Metal Precision Machine Assembler requires a combination of technical knowledge and communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and culture. Research the specific requirements and responsibilities of the Metal Precision Machine Assembler position you are applying for.

2. Review Key Skills and Experience

Highlight your skills in precision assembly, adjustment, inspection, and troubleshooting. Provide specific examples of your experience and accomplishments in these areas.

3. Practice Answering Common Interview Questions

Prepare for common interview questions such as:

- Describe your experience in precision metal assembly.

- How do you ensure the accuracy and quality of your work?

- Tell me about a time you had to troubleshoot an assembly issue.

4. Showcase Your Technical Knowledge

Demonstrate your understanding of precision measurement techniques, blueprint interpretation, and quality control procedures. If possible, bring examples of your work or technical certifications to support your claims.

5. Highlight Your Problem-Solving Abilities

Emphasize your ability to identify and resolve assembly problems. Provide examples of how you have used critical thinking and analytical skills to find solutions and improve processes.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal Precision Machine Assembler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.