Are you gearing up for an interview for a Valve Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Valve Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

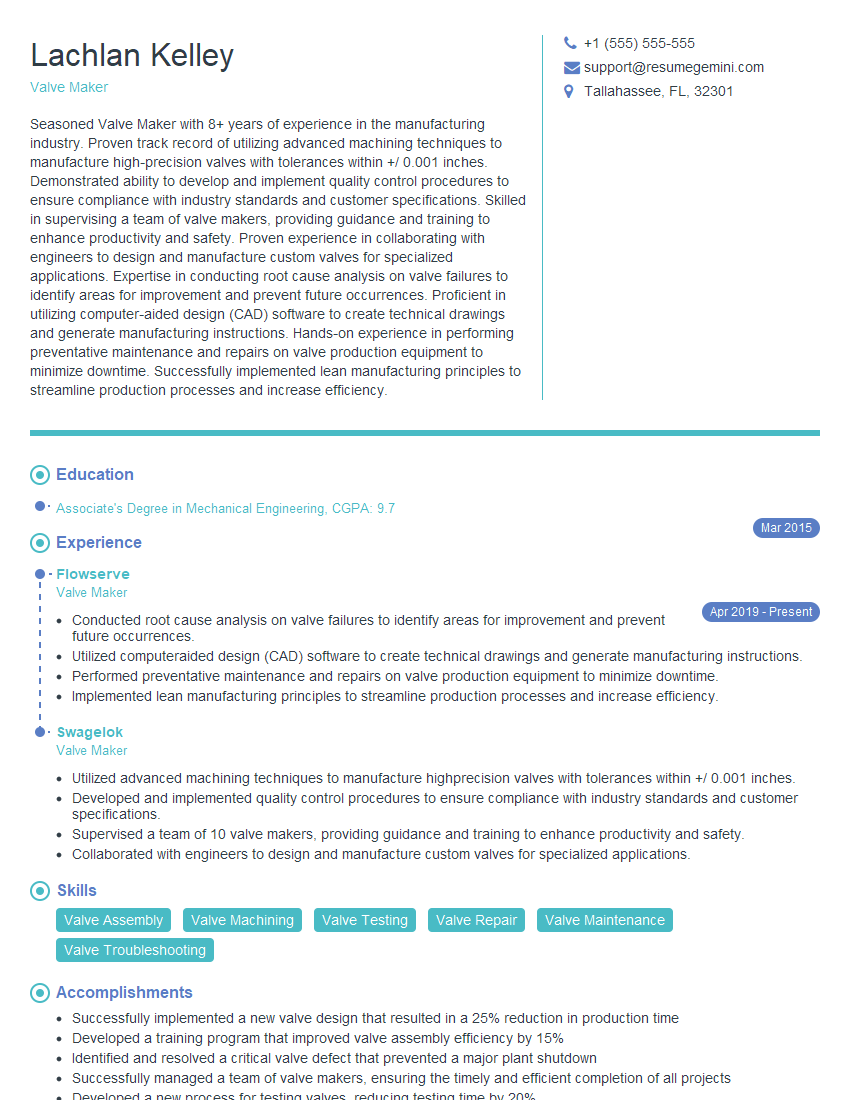

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Valve Maker

1. What is the difference between a gate valve and a globe valve?

A gate valve is a type of valve that uses a gate to stop the flow of fluid, while a globe valve uses a ball or plug to stop the flow of fluid. Gate valves are generally used for on/off applications, while globe valves can be used for both on/off and throttling applications. Gate valves have a lower pressure drop than globe valves, but globe valves are more resistant to wear and tear.

2. What is the purpose of a pressure relief valve?

Function of a Pressure Relief Valve

- Protects equipment from over-pressurization

- Releases excess pressure to a safe location

Types of Pressure Relief Valves

- Spring-loaded

- Pilot-operated

- Rupture disk

3. What are the different types of pipe fittings?

There are many different types of pipe fittings, each with its own unique purpose. Some of the most common types of pipe fittings include:

- Elbows: Used to change the direction of a pipe

- Tees: Used to connect three pipes together

- Crosses: Used to connect four pipes together

- Reducers: Used to reduce the diameter of a pipe

- Increasers: Used to increase the diameter of a pipe

- Couplings: Used to connect two pipes together

- Unions: Used to connect two pipes together and allow for easy disassembly

- Valves: Used to control the flow of fluid through a pipe

- Flanges: Used to connect two pipes together or to connect a pipe to a piece of equipment

4. What are the different types of valves?

There are many different types of valves, each with its own unique purpose. Some of the most common types of valves include:

- Gate valves: Used to stop the flow of fluid

- Globe valves: Used to control the flow of fluid

- Check valves: Used to prevent the flow of fluid in one direction

- Ball valves: Used to stop or start the flow of fluid

- Butterfly valves: Used to control the flow of fluid

- Diaphragm valves: Used to control the flow of fluid

5. What is the difference between a flow meter and a level meter?

A flow meter is used to measure the flow rate of a fluid, while a level meter is used to measure the level of a fluid. Flow meters can be used to measure the flow rate of liquids, gases, or solids, while level meters can be used to measure the level of liquids or solids.

6. What is the purpose of a pump?

A pump is a device that moves fluid from one place to another. Pumps can be used to move water, oil, gas, or other fluids. There are many different types of pumps, each with its own unique purpose. Some of the most common types of pumps include:

- Centrifugal pumps: Used to move large volumes of fluid at low pressures

- Positive displacement pumps: Used to move small volumes of fluid at high pressures

- Reciprocating pumps: Used to move medium volumes of fluid at medium pressures

- Submersible pumps: Used to move fluid from below the surface of the ground

7. What are the different types of pipe materials?

There are many different types of pipe materials, each with its own unique properties. Some of the most common types of pipe materials include:

- Steel: Strong and durable, but can be expensive

- Copper: Corrosion-resistant and easy to work with, but can be expensive

- PVC: Lightweight and inexpensive, but not as strong as steel or copper

- CPVC: Similar to PVC, but more resistant to chemicals

- PEX: Flexible and easy to install, but not as strong as steel or copper

8. What are the different methods of valve actuation?

There are many different methods of valve actuation, each with its own unique advantages and disadvantages. Some of the most common methods of valve actuation include:

- Manual actuation: The valve is operated by hand

- Electric actuation: The valve is operated by an electric motor

- Pneumatic actuation: The valve is operated by compressed air

- Hydraulic actuation: The valve is operated by hydraulic fluid

9. What are the different types of valve seals?

There are many different types of valve seals, each with its own unique properties. Some of the most common types of valve seals include:

- O-rings: Used to seal against liquids and gases

- V-rings: Used to seal against high pressures

- U-cups: Used to seal against both liquids and gases

- Diaphragms: Used to seal against both liquids and gases

- Lip seals: Used to seal against both liquids and gases

10. What are the different types of valve maintenance?

There are many different types of valve maintenance, each with its own unique purpose. Some of the most common types of valve maintenance include:

- Preventive maintenance: Performed on a regular basis to prevent problems from occurring

- Corrective maintenance: Performed to fix problems that have already occurred

- Predictive maintenance: Performed to identify potential problems before they occur

- Emergency maintenance: Performed to fix problems that require immediate attention

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Valve Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Valve Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Valve Makers are responsible for producing, modifying, and repairing valves to meet specific design requirements. They analyze blueprints, select materials, and operate various machines to create custom valves. Other responsibilities include:

1. Fabricate and assemble valves

According to drawings and specifications, measure and cut metal pipes, tubes, and other components. Weld, grind, and polish to ensure proper fit and functioning.

2. Inspect valves

Inspect completed valves to detect defects and ensure they meet quality standards. Conduct tests to verify performance and reliability.

3. Maintain and repair valves

Diagnose and repair faulty valves. Replace worn components and adjust valve settings to restore functionality and improve longevity.

4. Communicate with engineers and customers

Collaborate with engineers to understand design specifications and customer requirements. Provide updates on progress and discuss potential issues or solutions.

Interview Tips

Preparing thoroughly for a Valve Maker interview can increase your chances of success. Here are some helpful tips to consider:

1. Research the company and industry

Learn about the company’s products, services, and industry reputation. Demonstrate your knowledge of the valve manufacturing industry and current trends.

2. Study the job description

Review the job description carefully. Identify the key responsibilities and skills requested. Highlight your relevant experience and abilities that match the job requirements.

3. Practice common interview questions

Prepare for common interview questions related to your valve-making experience, technical skills, problem-solving abilities, and teamwork. Research specific examples to illustrate your responses.

4. Dress professionally

First impressions matter. Dress professionally to show respect for the interviewer and the company. Consider a formal suit or business casual attire.

5. Be punctual and enthusiastic

Arrive on time for your interview. Maintain a positive and enthusiastic attitude throughout the process. Your punctuality and enthusiasm will reflect your professionalism and interest in the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Valve Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Valve Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.