Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fiberglass Boat Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

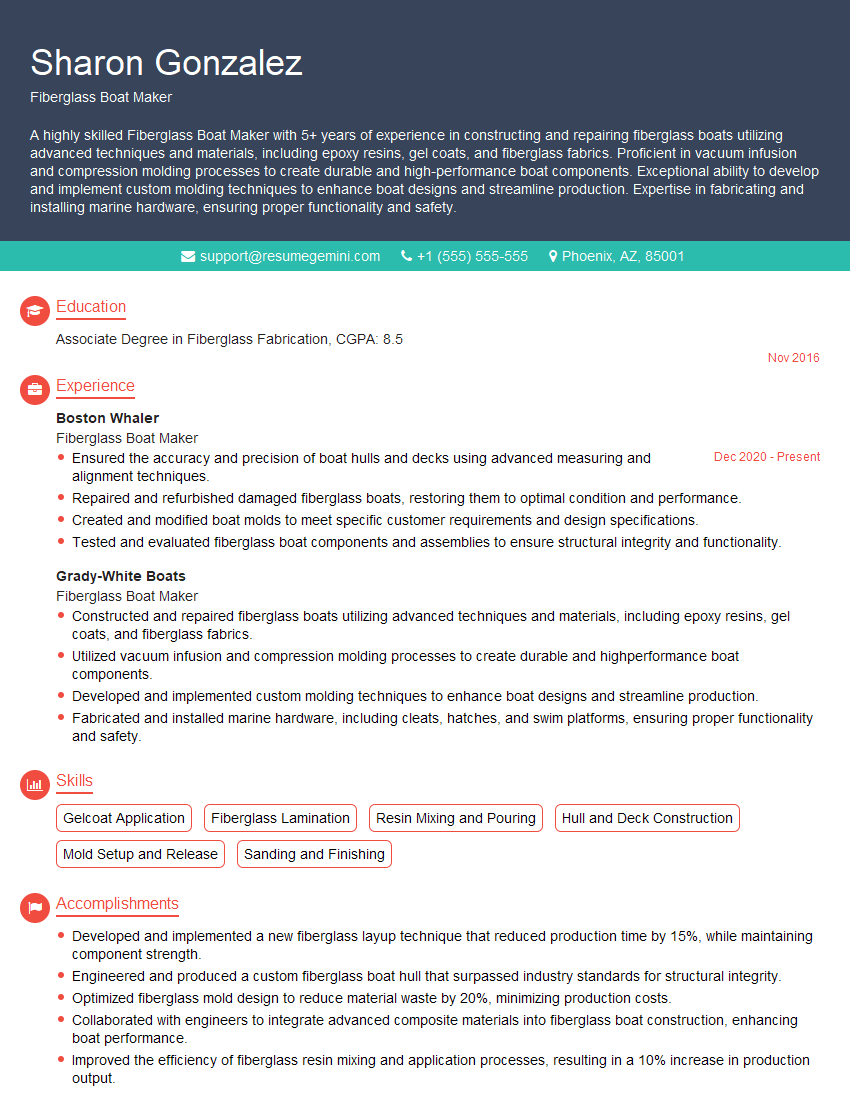

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Boat Maker

1. What are the different types of fiberglass used in boat building?

Fiberglass can be classified based on various factors such as glass type, resin type, and fiber orientation. Here are some common types used in boat building:

- E-Glass: Most common, durable, and cost-effective for boat hulls and decks.

- S-Glass: Stronger and stiffer than E-glass but more expensive, used for performance boats.

- C-Glass: Chemical-resistant and used for specialized applications, such as fuel tanks and chemical storage.

- Polyester Resin: Common and cost-effective, used for recreational boats and molds.

- Epoxy Resin: Stronger, more durable, and moisture-resistant, used for high-performance boats and marine applications.

2. Explain the process of laminating fiberglass.

Layup:

- Apply a release agent to the mold to prevent sticking.

- Cut and position the fiberglass mats or fabrics according to the design.

Resin Application:

- Mix the fiberglass resin and hardener according to the manufacturer’s instructions.

- Apply the resin evenly over the fiberglass layers using a brush, roller, or vacuum bagging.

Curing:

- Allow the resin to cure at the recommended temperature and humidity.

- Use heat lamps or ovens to accelerate curing in cold or humid conditions.

3. What are the key factors that determine the strength of a fiberglass boat?

- Glass-to-resin ratio: Higher glass content increases strength.

- Laminate thickness: Thicker laminates provide more structural support.

- Fiberglass orientation: Biaxial or triaxial fabrics offer improved strength in multiple directions.

- Resin selection: Epoxy resin provides higher strength and durability than polyester resin.

- Layup technique: Proper layup techniques, such as proper compaction and void removal, ensure optimal strength.

4. How do you repair cracks or damage in a fiberglass boat?

- Grind or sand the damaged area to create a clean surface.

- Apply a layer of fiberglass cloth or mat over the damaged area.

- Saturate the fiberglass with resin and allow it to cure.

- Sand and smooth the repaired area to match the original contour.

5. What safety precautions should be taken when working with fiberglass?

- Wear appropriate protective gear, such as gloves, masks, and respirators.

- Ventilate the workspace adequately to avoid inhaling harmful fumes.

- Avoid contact with skin and eyes.

- Keep resin and hardener away from flammable materials and sources of heat.

- Dispose of waste materials properly according to environmental regulations.

6. How do you determine the appropriate resin-to-hardener ratio for a specific fiberglass project?

The resin-to-hardener ratio is crucial for achieving the optimal cure and strength of the fiberglass laminate. Here’s how to determine it:

- Manufacturer’s Instructions: Consult the technical data sheet provided by the resin manufacturer, which specifies the recommended ratio.

- Trial and Error: Mix small batches of resin and hardener at different ratios and observe the curing behavior. The ideal ratio will result in a strong, well-cured laminate without excessive heat generation.

7. Describe the different methods used to apply fiberglass reinforcement.

- Hand Layup: Applying fiberglass mats or fabrics by hand and saturating them with resin using brushes or rollers.

- Spray-up: Using a spray gun to apply a mixture of chopped fiberglass and resin directly to the mold.

- Vacuum Bagging: Placing the fiberglass laminate in a mold and applying a vacuum to remove air and excess resin, resulting in a strong and uniform laminate.

- Vacuum Infusion: Injecting resin into the fiberglass laminate under vacuum, ensuring complete resin penetration and minimizing voids.

8. Explain the importance of controlling temperature and humidity during the fiberglass curing process.

- Temperature: Elevated temperatures accelerate the curing process, but excessive heat can cause exothermic reactions and weakening of the laminate. Conversely, cold temperatures slow down curing.

- Humidity: High humidity can cause the resin to absorb moisture, which can lead to blisters and reduced strength. Controlling humidity levels ensures a proper cure and prevents defects.

9. What are the different types of gelcoats used in fiberglass boat construction?

- Polyester Gelcoats: Most common, provide UV protection, color, and a smooth finish.

- Epoxy Gelcoats: More durable, resistant to chemicals, and provide superior gloss retention.

- Vinyl Ester Gelcoats: Offer excellent barrier properties, protecting against moisture and osmotic blistering.

10. How do you ensure proper adhesion between the fiberglass hull and the deck of a boat?

- Prepare the surfaces by sanding and cleaning.

- Apply a compatible adhesive, such as vinylester resin or epoxy, to both surfaces.

- Secure the hull and deck together using bolts, clamps, or other mechanical fasteners.

- Allow the adhesive to cure properly before removing any temporary supports.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Boat Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Boat Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiberglass Boat Makers are responsible for crafting, repairing, and maintaining fiberglass boats, employing specialist knowledge of fiberglass construction and boatbuilding techniques. Their primary duties include:

1. Fiberglass Fabrication

• Constructing fiberglass boat hulls, decks, and various components using molds and lay-up techniques.

• Applying fiberglass mat, cloth, and resin to create sturdy and watertight structures.

2. Boat Assembly

• Assembling and installing boat components, including decks, gunwales, bulkheads, and hardware.

• Ensuring proper fit and alignment of all components to meet design specifications.

3. Mold Preparation

• Preparing and maintaining molds used for fiberglass fabrication.

• Ensuring molds are clean, free of defects, and properly coated with release agents.

4. Repair and Maintenance

• Inspecting boats for damage and performing necessary repairs.

• Repairing cracks, holes, and other defects using fiberglass materials and techniques.

5. Quality Control

• Monitoring the quality of fiberglass work throughout the fabrication and assembly process.

• Conducting inspections and testing to ensure boats meet safety and performance standards.

Interview Tips

1. Research the Company and Industry

• Learn about the company’s history, products, and culture.

• Stay up-to-date on industry trends and advancements in fiberglass boatbuilding.

2. Practice Your Answers

• Prepare for common interview questions related to your skills, experience, and knowledge.

• Rehearse your answers to showcase your confidence and preparedness.

3. Highlight Your Skills and Experience

• Emphasize your hands-on experience in fiberglass fabrication, boat assembly, and repair.

• Provide specific examples of projects you’ve worked on, demonstrating your technical abilities.

4. Showcase Your Passion for Boatbuilding

• Express your genuine interest in fiberglass boatbuilding and your desire to contribute to the field.

• Discuss your knowledge of different boat types and construction methods.

5. Ask Informed Questions

• Prepare thoughtful questions about the company’s boatbuilding process, quality standards, and future plans.

• Asking informed questions shows your engagement and interest in the position.

Additional Tips

• Dress professionally and arrive punctually for the interview.

• Bring a portfolio or examples of your fiberglass work to showcase your skills.

• Be prepared to discuss safety precautions and industry regulations related to fiberglass boatbuilding.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Fiberglass Boat Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.