Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fiberglasser interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fiberglasser so you can tailor your answers to impress potential employers.

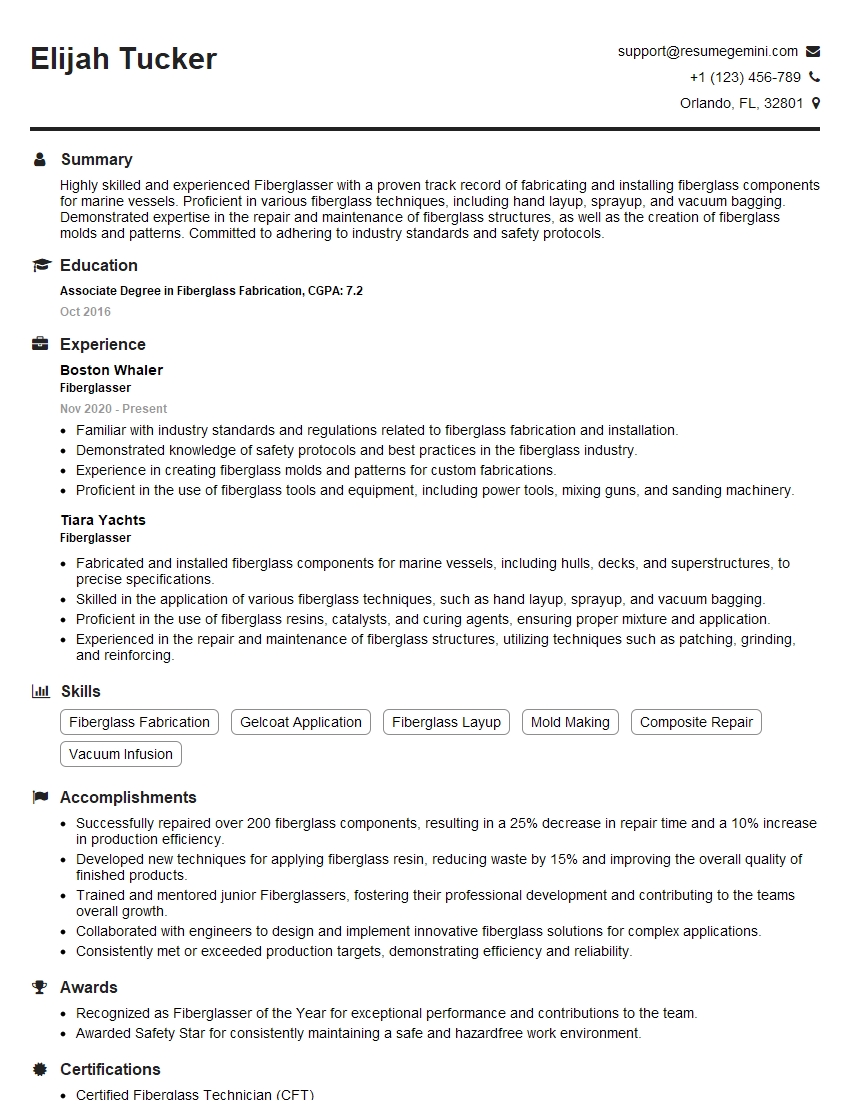

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglasser

1. What is the most important thing to consider when choosing a fiberglass resin?

The most important thing to consider when choosing a fiberglass resin is the intended use of the finished product. Different resins have different properties, such as strength, flexibility, and resistance to chemicals and UV radiation. It is important to choose a resin that is well-suited for the specific project.

2. What are the different types of fiberglass cloth?

Woven cloth

- Plain weave: The most common type of weave, offering a good balance of strength and flexibility.

- Twill weave: A stronger and more flexible weave than plain weave, but also more expensive.

Non-woven cloth

- Chopped strand mat: Made from randomly oriented fibers, offering good strength and impact resistance.

- Continuous strand mat: Made from long, parallel fibers, offering very high strength.

3. What is the difference between a catalyzed resin and a non-catalyzed resin?

A catalyzed resin is a resin that has been mixed with a catalyst, which is a chemical that speeds up the curing process. A non-catalyzed resin is a resin that has not been mixed with a catalyst. Catalyzed resins cure more quickly than non-catalyzed resins, but they also have a shorter working time.

4. What are the steps involved in laminating fiberglass?

- Prepare the surface to be laminated.

- Apply a layer of catalyzed resin to the surface.

- Apply a layer of fiberglass cloth.

- Repeat steps 2 and 3 until the desired thickness is achieved.

- Cure the laminate at the appropriate temperature and humidity.

5. What are the most common problems that can occur during fiberglass lamination?

- Air bubbles: Air bubbles can cause the laminate to be weak and can also create a breeding ground for bacteria.

- Resin starvation: Resin starvation occurs when there is not enough resin to wet out the fiberglass cloth, which can result in a weak and brittle laminate.

- Curing problems: Curing problems can occur if the laminate is not cured at the appropriate temperature and humidity, which can result in a laminate that is not fully cured and is weak.

6. What are the different types of fiberglass finishes?

- Gel coat: A high-gloss finish that is applied to the surface of the laminate.

- Topcoat: A less glossy finish that is applied to the surface of the laminate to protect it from UV radiation.

- Paint: A variety of paints can be applied to the surface of the laminate to provide a desired color or finish.

7. What are the safety precautions that should be taken when working with fiberglass?

- Wear a respirator when working with fiberglass dust or fumes.

- Wear gloves and eye protection when handling fiberglass.

- Do not smoke or eat while working with fiberglass.

- Work in a well-ventilated area.

- Clean up all fiberglass dust and debris after finishing work.

8. What are the different types of fiberglass applications?

- Automotive: Fiberglass is used in the production of car bodies, hoods, and other parts.

- Marine: Fiberglass is used in the construction of boats, kayaks, and other watercraft.

- Aerospace: Fiberglass is used in the production of aircraft components, such as fairings and wings.

- Construction: Fiberglass is used in the production of roofing, siding, and other building materials.

- Medical: Fiberglass is used in the production of medical devices, such as casts and prosthetics.

9. What are the advantages of using fiberglass?

- Strength: Fiberglass is a very strong and durable material.

- Lightweight: Fiberglass is a very lightweight material, making it easy to handle and transport.

- Corrosion resistance: Fiberglass is resistant to corrosion, making it ideal for use in applications where it will be exposed to moisture or chemicals.

- Versatility: Fiberglass can be molded into a variety of shapes and sizes, making it suitable for a wide range of applications.

10. What are the disadvantages of using fiberglass?

- Cost: Fiberglass can be more expensive than other materials, such as wood or metal.

- Brittle: Fiberglass is a brittle material, which means it can be easily broken if it is not handled carefully.

- Combustible: Fiberglass is a combustible material, which means it can burn if it is exposed to fire.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglasser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglasser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiberglassers are skilled craftsmen who work with fiberglass materials to create a variety of products, including boats, automotive parts, and wind turbine blades. They use a variety of techniques to shape and reinforce fiberglass, including hand lay-up, spray-up, and vacuum bagging.

1. Prepare surfaces for fiberglass application

This includes cleaning, sanding, and applying a release agent.

2. Cut and shape fiberglass materials

Fiberglassers use a variety of tools to cut and shape fiberglass, including scissors, knives, and saws.

3. Apply fiberglass to surfaces

Fiberglassers use a variety of techniques to apply fiberglass to surfaces, including hand lay-up, spray-up, and vacuum bagging.

4. Cure fiberglass

Fiberglassers use a variety of methods to cure fiberglass, including heat, pressure, and vacuum.

5. Inspect and finish fiberglass products

Fiberglassers inspect fiberglass products for defects and finish them by sanding, buffing, and painting.

Interview Tips

Preparing for an interview for a fiberglasser position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to talk about your skills and experience

The interviewer will want to know about your skills and experience as a fiberglasser. Be prepared to talk about your experience in detail, including the types of projects you have worked on and the techniques you have used.

4. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the company and the position, and to show that you are interested and engaged.

5. Follow up after the interview

After the interview, it is important to follow up with the interviewer. This can be done by sending a thank-you note or email, or by calling the interviewer to check on the status of your application.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fiberglasser interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!