Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fiberglass Laminator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

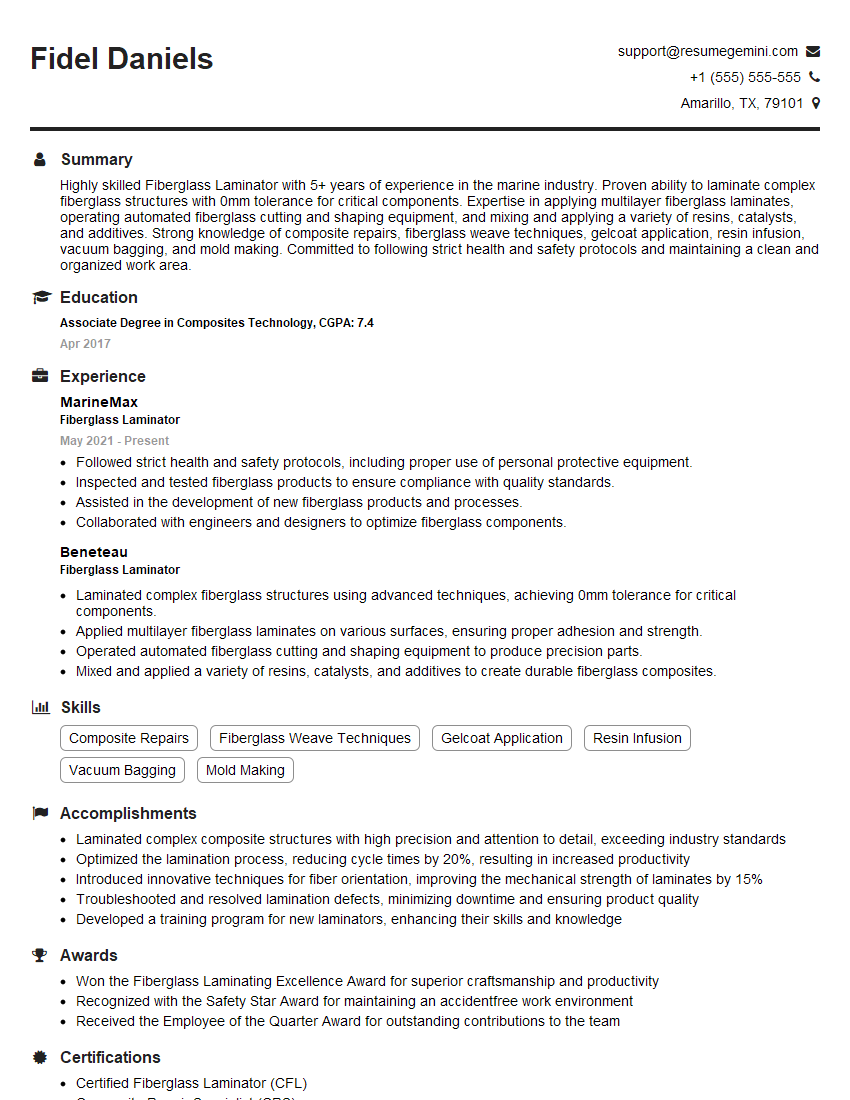

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Laminator

1. What are the different types of fiberglass materials used in lamination?

There are various types of fiberglass materials used in lamination, each with its unique properties:

- E-glass: Commonly used in electrical applications, providing high strength and electrical resistance.

- S-glass: Offers exceptional strength and stiffness, ideal for high-performance components.

- C-glass: Chemical-resistant and corrosion-resistant, suitable for applications in corrosive environments.

- AR-glass: Alkali-resistant, designed to withstand alkaline environments commonly found in concrete structures.

- Quartz or Silica Glass: High-temperature resistant and low coefficient of thermal expansion, used in specialty applications.

2. Describe the process of preparing a surface for fiberglass lamination.

Surface Preparation

- Cleaning: Remove dirt, oil, and debris from the surface using solvents or detergents.

- Sanding: Roughen the surface with sandpaper to provide a good bonding surface for the fiberglass.

- Masking: Protect areas that should not be laminated using masking tape or similar materials.

Primer Application (if required)

Apply a primer to enhance adhesion and improve the bond between the laminating resin and the surface.

3. Explain the different methods of applying fiberglass resin during lamination.

There are two main methods of applying fiberglass resin during lamination:

- Manual Lay-Up: Resin is applied manually using brushes, rollers, or squeegees, followed by the placement of fiberglass mat or tessuto.

- Vacuum Infusion: Resin is infused into a sealed mold containing the fiberglass material under vacuum, resulting in a higher fiber-to-resin ratio.

4. How do you ensure proper curing of fiberglass laminates?

Proper curing of fiberglass laminates is essential for achieving optimal strength and durability:

- Temperature Control: Maintain the curing temperature within the specified range recommended by the resin manufacturer.

- Curing Time: Allow for sufficient curing time as per the resin specifications.

- Post-Curing: Consider post-curing at elevated temperatures to further enhance the laminate’s properties.

- Monitoring: Use monitoring devices like thermocouples to track the temperature during curing.

5. What are the common defects that can occur during fiberglass lamination and how can they be prevented?

Common defects in fiberglass lamination include:

- Dry Spots: Insufficient resin application, resulting in areas of weak bonding.

- Air Bubbles: Trapped air pockets that compromise the laminate’s strength.

- Fiber Orientation: Improper alignment of fiberglass fibers, affecting the laminate’s structural integrity.

- Delamination: Separation between different layers of the laminate.

These defects can be prevented through proper surface preparation, accurate resin application, thorough degassing, and careful handling.

6. Describe the safety precautions that must be taken when working with fiberglass.

Fiberglass work requires strict safety measures:

- Proper PPE: Wear protective gear including gloves, safety glasses, and respirators.

- Handling Precautions: Handle fiberglass materials carefully to avoid splinters and abrasions.

- Ventilation: Ensure adequate ventilation to dispel harmful fumes and dust.

- Containment Measures: Prevent the spread of fiberglass particles by containing work areas.

- Waste Disposal: Dispose of fiberglass waste properly according to environmental regulations.

7. What types of tools and equipment are commonly used in fiberglass lamination?

Essential tools and equipment for fiberglass lamination include:

- Brushes, Rollers, and Squeegees: For applying resin and spreading fiberglass materials.

- Vacuum Pump and System: For vacuum infusion techniques.

- Sanders and Grinders: For surface preparation and finishing.

- Mixing Tools: For preparing fiberglass resin.

- Safety Gear: As mentioned in question 6.

8. How do you determine the correct fiberglass-to-resin ratio for a specific application?

The optimal fiberglass-to-resin ratio depends on the application and material properties:

- Structural Applications: Higher fiberglass content (60-70%) to enhance strength.

- Cosmetics: Lower fiberglass content (30-40%) for a smoother surface finish.

- Resin Type: Different resins have varying recommended ratios.

- Experimental Testing: Conduct small-scale tests to determine the optimal ratio for specific applications.

9. Explain the importance of resin selection in fiberglass lamination.

Resin selection is crucial for the performance and longevity of fiberglass laminates:

- Mechanical Properties: Resins vary in strength, stiffness, and toughness.

- Chemical Resistance: Resins offer different levels of resistance to chemicals, solvents, and environmental factors.

- Curing Characteristics: Resins have varying curing times and temperatures, affecting production efficiency.

- Viscosity: Resin viscosity influences application methods and laminate quality.

- Cost and Availability: Consider the cost and availability of the resin for the project.

10. Describe the quality control procedures you follow during fiberglass lamination.

Quality control is essential to ensure the integrity of fiberglass laminates:

- Incoming Material Inspection: Inspect fiberglass materials and resins for defects and conformity.

- Process Monitoring: Track curing times, temperatures, and resin application techniques.

- Non-Destructive Testing: Perform tests such as ultrasonic or tap testing to identify voids or delaminations.

- Destructive Testing: Conduct tests like tensile or flexural testing to assess the mechanical properties of the laminate.

- Documentation: Maintain records of all quality control procedures and results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Laminator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Laminator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiberglass Laminators are responsible for creating fiberglass products by layering and bonding fiberglass materials together. Their primary duties include:

1. Layering and Bonding Fiberglass Materials

Laminators apply layers of fiberglass cloth or matting to molds or surfaces, using brushes or rollers to spread and smooth resin. They bond the layers together using epoxy, polyester, or vinyl ester resins.

- Select and prepare fiberglass materials, such as cloth, mat, and resin.

- Layer and bond fiberglass materials according to specifications, using brushes or rollers to apply resin.

- Ensure proper curing of the fiberglass laminate by controlling temperature and humidity.

2. Operating Laminating Equipment

Laminators operate specialized equipment, such as spray guns, gel coaters, and vacuum bagging systems, to apply fiberglass materials and create desired shapes.

- Operate spray guns to apply gel coat or resin to surfaces.

- Use gel coaters to create a smooth, protective layer on fiberglass surfaces.

- Utilize vacuum bagging systems to remove air bubbles and ensure proper bonding.

3. Inspecting and Finishing Products

Laminators inspect finished products for defects, such as air bubbles, voids, or uneven surfaces. They also perform finishing tasks, such as sanding, trimming, and polishing.

- Inspect fiberglass products for defects and imperfections.

- Sand, trim, and polish fiberglass surfaces to achieve desired finish.

- Repair or replace defective areas as needed.

4. Maintaining Equipment and Workspace

Laminators maintain their equipment and workspaces to ensure efficient and safe operation. They clean and calibrate equipment, and dispose of hazardous materials properly.

- Clean and maintain laminating equipment, including spray guns, gel coaters, and vacuum bagging systems.

- Dispose of hazardous materials, such as resins and solvents, according to environmental regulations.

- Maintain a clean and organized workspace to promote safety and efficiency.

Interview Tips

To prepare for a Fiberglass Laminator interview, consider the following tips:

1. Research the Company and Position

Learn about the company’s products, services, and industry. Understand the specific job requirements and responsibilities.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in fiberglass lamination, as well as your experience in operating laminating equipment. Quantify your accomplishments whenever possible.

3. Practice Common Interview Questions

Prepare for common interview questions, such as those related to your skills, experience, and work ethic. Consider the following:

4. Dress Professionally and Arrive on Time

Make a positive impression by dressing professionally and arriving on time for your interview. This shows that you respect the interviewer and the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Fiberglass Laminator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Fiberglass Laminator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.