Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Certified Composites Technician (CCT) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Certified Composites Technician (CCT) so you can tailor your answers to impress potential employers.

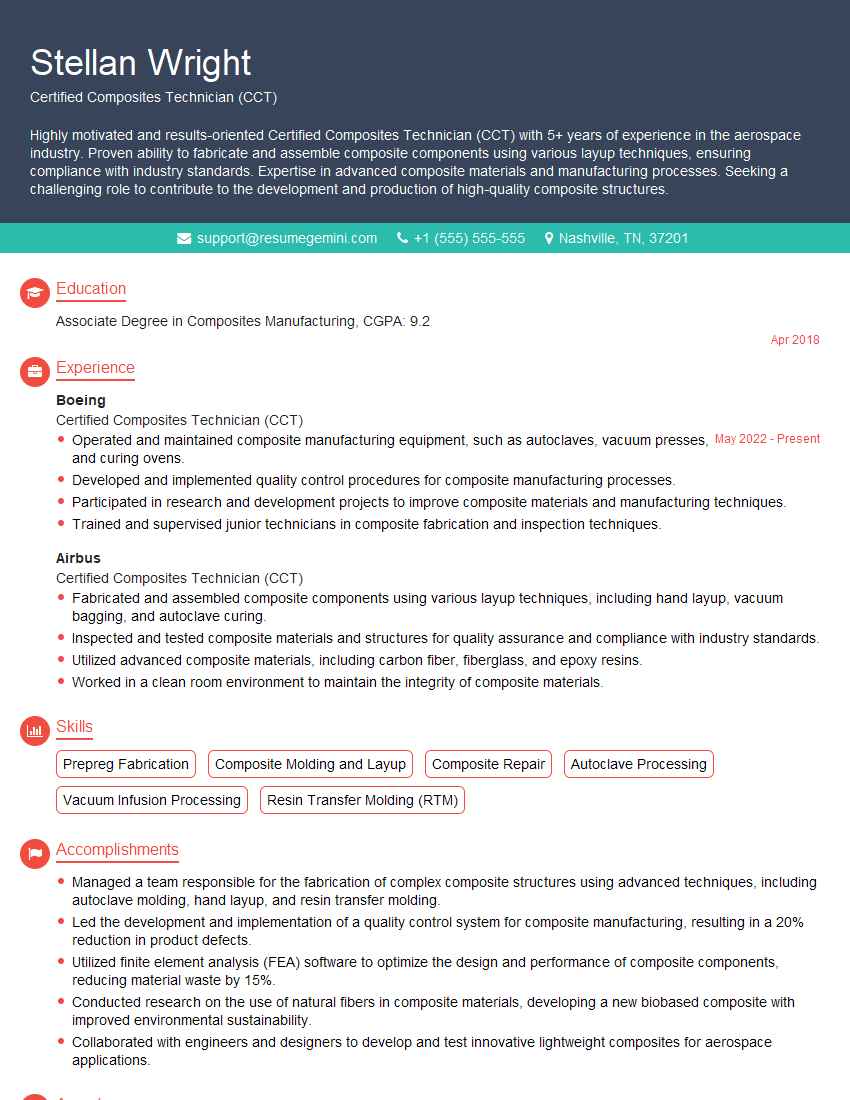

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Certified Composites Technician (CCT)

1. What is the difference between a laminate and a composite?

A laminate is a stack of two or more layers of material, while a composite is a material that is made up of two or more different materials that are combined to create a new material with different properties.

2. What is the difference between open and closed mold processes?

Open Mold Processes

- Lay-up of dry reinforcement is done in an open mold

- Resin is applied to the dry reinforcement and then cured

- Examples: hand lay-up, spray-up, and filament winding

Closed Mold Processes

- Reinforcement is placed in a closed mold

- Resin is injected into the mold and then cured

- Examples: vacuum infusion, resin transfer molding, and compression molding

3. What are the different types of composite materials?

There are many different types of composite materials, but the most common are:

- Fiber-reinforced composites: These composites are made of a reinforcing fiber, such as carbon fiber, glass fiber, or aramid fiber, that is embedded in a matrix material, such as epoxy, polyester, or vinyl ester.

- Particle-reinforced composites: These composites are made of a reinforcing particle, such as metal particles, ceramic particles, or carbon black, that is embedded in a matrix material, such as epoxy, polyester, or vinyl ester.

- Structural composites: These composites are made of a reinforcing material, such as carbon fiber or glass fiber, that is embedded in a matrix material, such as epoxy, polyester, or vinyl ester. Structural composites are used in a wide variety of applications, including aerospace, automotive, and marine.

4. What are the different properties of composite materials?

Composite materials have a wide range of properties, including:

- Strength: Composite materials are very strong, and they can withstand high loads without breaking.

- Stiffness: Composite materials are very stiff, and they do not deform easily under load.

- Lightweight: Composite materials are very lightweight, and they are often used in applications where weight is a concern.

- Corrosion resistance: Composite materials are resistant to corrosion, and they can be used in applications where exposure to harsh chemicals is a concern.

- Electrical conductivity: Composite materials can be either conductive or non-conductive, depending on the materials that are used to make them.

5. What are the different applications of composite materials?

Composite materials are used in a wide variety of applications, including:

- Aerospace: Composite materials are used in a variety of aerospace applications, such as aircraft wings, fuselages, and spacecraft.

- Automotive: Composite materials are used in a variety of automotive applications, such as body panels, bumpers, and interior components.

- Marine: Composite materials are used in a variety of marine applications, such as boat hulls, decks, and sails.

- Wind energy: Composite materials are used in a variety of wind energy applications, such as wind turbine blades and towers.

- Medical: Composite materials are used in a variety of medical applications, such as prosthetics, implants, and surgical instruments.

6. What are the challenges in the field of composite materials?

The field of composite materials is constantly evolving, and there are a number of challenges that need to be addressed in order to continue to advance the technology.

- Cost: Composite materials can be expensive to manufacture, which can limit their use in some applications.

- Processing: Composite materials can be difficult to process, which can also limit their use in some applications.

- Design: The design of composite structures can be complex, and it can be difficult to predict the performance of these structures under different loading conditions.

7. What are the trends in the field of composite materials?

The field of composite materials is constantly evolving, and there are a number of trends that are likely to continue in the future.

- Increased use of advanced materials: Advanced materials, such as carbon fiber and graphene, are becoming more affordable and easier to process, which will lead to increased use of these materials in composite applications.

- Increased use of automation: Automation is becoming more common in the manufacture of composite materials, which will help to reduce costs and improve quality.

- Increased use of simulation: Simulation is becoming more common in the design of composite structures, which will help to predict the performance of these structures under different loading conditions.

8. What is the role of a Certified Composites Technician (CCT)?

A CCT is responsible for the fabrication and repair of composite structures. CCTs work in a variety of industries, including aerospace, automotive, and marine. They use a variety of skills and techniques to fabricate and repair composite structures, including:

- Lay-up: CCTs lay up dry reinforcement in a mold.

- Resin application: CCTs apply resin to the dry reinforcement.

- Curing: CCTs cure the resin to create a solid composite structure.

- Repair: CCTs repair damaged composite structures.

9. What are the qualifications for a CCT?

To become a CCT, you must have the following qualifications:

- High school diploma or equivalent

- Completion of a CCT training program

- Experience in the fabrication and repair of composite structures

- Certification from the American Composites Manufacturers Association (ACMA)

10. What is the salary range for a CCT?

The salary range for a CCT varies depending on experience, location, and industry. According to the ACMA, the average salary for a CCT is $60,000 per year.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Certified Composites Technician (CCT).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Certified Composites Technician (CCT)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Certified Composites Technicians (CCTs) are responsible for fabricating, inspecting, and repairing composite structures in various industries, including aerospace, automotive, and marine. They work with high-performance materials such as carbon fiber, fiberglass, and epoxy resins.

1. Fabrication

CCTs fabricate composite parts by following detailed engineering drawings and specifications. They use various techniques such as hand layup, vacuum bagging, and autoclave curing to create complex shapes and structures.

- Interpret engineering drawings and specifications to determine material selection and fabrication methods.

- Lay up composite materials using hand layup, vacuum bagging, or autoclave curing techniques.

- Inspect fabricated parts for quality and conformance to specifications.

2. Inspection

CCTs inspect composite structures using non-destructive testing (NDT) methods such as ultrasonic, X-ray, and thermography to identify defects and ensure structural integrity.

- Perform NDT inspections to identify defects in composite structures.

- Interpret NDT results and make recommendations for repairs or corrective actions.

- Maintain inspection records and documentation.

3. Repair

CCTs repair damaged composite structures using techniques such as patching, bonding, and reinforcement. They ensure that repaired structures meet original design specifications and safety standards.

- Identify and assess damage to composite structures.

- Develop and implement repair plans based on damage assessment.

- Perform repairs using approved techniques and materials.

4. Quality Assurance

CCTs play a critical role in maintaining quality assurance in composite fabrication and repair. They adhere to industry standards and regulations to ensure the safety and reliability of composite structures.

- Monitor and maintain quality control procedures throughout the fabrication and repair process.

- Document all quality assurance activities and maintain records.

- Collaborate with engineers and quality assurance personnel to improve processes.

Interview Tips

To ace an interview for a Certified Composites Technician position, it is essential to prepare thoroughly and highlight your skills and experience in the field. Here are some interview tips and preparation strategies:

1. Research the Company and Position

Research the company you are applying to, including its mission, values, and current projects. This will help you understand the company’s culture and the specific requirements of the position.

- Visit the company website to learn about their products, services, and industry reputation.

- Review the job description carefully and identify the key responsibilities and qualifications required.

2. Highlight Your Skills and Experience

During the interview, clearly articulate your skills and experience in composite fabrication, inspection, repair, and quality assurance. Use specific examples to demonstrate your proficiency in these areas.

- Quantify your accomplishments whenever possible, using metrics such as the number of parts fabricated, defects detected, or repairs completed.

- Emphasize your experience with industry-standard NDT techniques and composite materials.

3. Demonstrate Technical Knowledge

Be prepared to answer technical questions about composite materials, fabrication techniques, and inspection methods. Show that you have a strong understanding of the fundamental principles and best practices in the field.

- Study composite materials, including their properties, advantages, and limitations.

- Familiarize yourself with different fabrication techniques, such as hand layup, vacuum bagging, and autoclave curing.

4. Prepare for Behavioral Questions

Interviewers often ask behavioral questions to assess your soft skills and work style. Practice answering questions about teamwork, problem-solving, and conflict resolution.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your behavior.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Show that you are passionate about composite technology and eager to contribute to the team. Dress professionally, arrive on time, and be respectful of the interviewer’s time.

- Practice your answers to common interview questions to build confidence and fluency.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Certified Composites Technician (CCT) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!