Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Chronometer Assembler and Adjuster interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Chronometer Assembler and Adjuster so you can tailor your answers to impress potential employers.

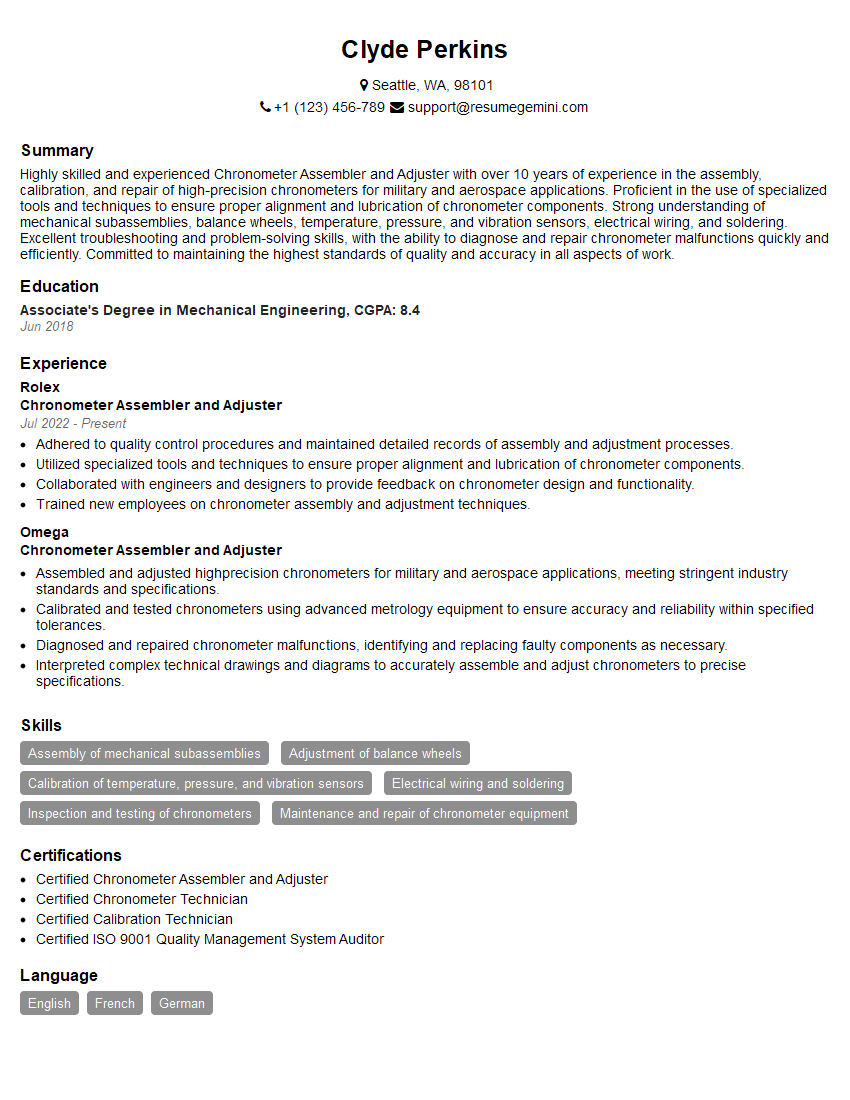

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chronometer Assembler and Adjuster

1. Describe the process of assembling a chronometer balance?

The process of assembling a chronometer balance involves several intricate steps:

- Preparing the balance rim: The rim is carefully rounded and polished to ensure a precise circular shape.

- Attaching the balance staff: The balance staff is inserted into the rim and secured with a spring or screw.

- Mounting the balance spring: The balance spring is attached to the balance staff at specific points, ensuring the proper tension and resonance.

- Adjusting the balance weight: Small weights are added or removed to achieve the desired weight and balance.

- Poising the balance: The balance is tested for poise, ensuring it rotates evenly without bias.

2. How do you ensure the accuracy of a chronometer movement?

Ensuring the accuracy of a chronometer movement requires a combination of precise assembly, adjustment, and testing:

- Lubrication: The movement is sparingly lubricated to minimize friction and wear.

- Regulation: The balance spring is adjusted to ensure the correct rate and amplitude of oscillation.

- Temperature compensation: A temperature-compensating mechanism, such as a bimetallic strip, is used to offset temperature variations.

- Testing: The movement is subjected to rigorous testing in different positions and temperatures to verify its accuracy.

- Certification: Once the movement meets the required standards, it undergoes certification by an official body.

3. What are the common materials used for chronometer components?

Chronometer components are typically made of high-quality materials to ensure durability and accuracy:

- Balance rim: Aluminum alloys, titanium, beryllium

- Balance staff: Steel, Nivarox

- Balance spring: Nivarox alloy, Elinvar

- Escapement: Steel, hardened alloys

- Jewels: Synthetic rubies or sapphires

4. Describe the role of the escapement in a chronometer movement?

The escapement is a crucial component of a chronometer movement, enabling it to keep time accurately:

- Controlling the balance: The escapement releases the balance spring energy in controlled intervals.

- Maintaining the amplitude: The escapement provides the impulse to the balance, maintaining its amplitude and rate.

- Preventing overwinding: The escapement prevents the movement from overwinding, protecting the components from damage.

- Accurate timekeeping: The precision of the escapement ensures the accurate transfer of energy to the balance, resulting in consistent timekeeping.

5. How do you adjust the beat error in a chronometer movement?

To adjust the beat error in a chronometer movement, follow these steps:

- Identify the error: Place the movement in the beat setting and observe the movement of the balance wheel.

- Correct the adjustment: Adjust the position of the pallets by bending them slightly with special tools.

- Test and refine: Repeat the beat setting and fine-tune the adjustment until the error is minimized.

- Lubricate and reassemble: After adjustment, lubricate the pallets and reassemble the movement.

6. What are the different types of chronometer adjustments and their significance?

There are several types of chronometer adjustments, each serving a specific purpose:

- Temperature adjustments: Compensate for temperature variations and maintain accuracy in different environments.

- Position adjustments: Ensure accuracy in various positions, such as vertical and horizontal planes.

- Isochronism adjustments: Correct for changes in the balance spring’s elasticity, ensuring consistent amplitude and rate.

- Rate adjustments: Regulate the rate of the movement to meet specific accuracy standards.

7. How do you troubleshoot and repair a chronometer movement?

Troubleshooting and repairing a chronometer movement requires a methodical approach:

- Diagnose the problem: Identify the source of the problem through observation, testing, and logical analysis.

- Repair the fault: Use appropriate tools and techniques to repair or replace faulty components.

- Regulate and adjust: After repair, regulate and adjust the movement to ensure accuracy and optimal performance.

- Test and verify: Conduct thorough testing to verify the repair and ensure the movement meets specifications.

8. Describe the importance of precision tools and equipment in chronometer assembly and adjustment?

Precision tools and equipment are essential for accurate and efficient chronometer assembly and adjustment:

- Micrometer calipers: Measure diameters and dimensions of components precisely.

- Dial indicators: Detect minute movements and adjust components within tight tolerances.

- Timing machines: Test the rate and amplitude of the movement to ensure accuracy.

- Specialized screwdrivers and pliers: Handle delicate components without damaging them.

- Magnifiers and microscopes: Inspect and manipulate components at high magnifications.

9. How do you stay up-to-date with advancements in chronometer technology and techniques?

To stay current with advancements, consider the following initiatives:

- Attend industry events and workshops: Engage with experts and learn about the latest techniques.

- Read industry publications and research papers: Stay informed about new materials, methods, and technologies.

- Network with other chronometer assemblers and adjusters: Exchange knowledge and experiences to enhance your skills.

- Explore online resources and forums: Access a wealth of information and connect with the global chronometer community.

10. What are the qualities and skills required to be a successful chronometer assembler and adjuster?

Qualities and skills essential for success in this field include:

- Meticulous attention to detail: Ensuring precision in every aspect of assembly and adjustment.

- Exceptional dexterity and hand-eye coordination: Handling delicate components and performing intricate tasks.

- Analytical and troubleshooting skills: Identifying and resolving technical issues effectively.

- Knowledge of horological principles: Understanding the mechanics and physics of chronometers.

- Patience and perseverance: Working diligently to achieve the highest levels of accuracy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chronometer Assembler and Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chronometer Assembler and Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A chronometer assembler and adjuster is a highly skilled professional responsible for the assembly, adjustment, and testing of marine and precision timekeeping instruments known as chronometers. These devices are critical for accurate timekeeping in navigation, surveying, and scientific applications.

1. Assembly and Disassembly

Assembling and disassembling chronometers is a delicate process that requires precision and attention to detail. The assembler follows precise specifications to correctly place and secure all components, ensuring proper functionality.

- Disassembling chronometers to identify and replace faulty parts

- Reassembling chronometers after repairs or maintenance

2. Adjustment and Calibration

After assembly, the assembler adjusts and calibrates the chronometer to meet specific accuracy standards. This involves adjusting the balance spring, hairspring, and other components to ensure optimal performance.

- Calibrating the chronometer against a reference timepiece

- Making fine adjustments to the escapement and other mechanical components

3. Testing and Inspection

Once adjusted, the assembler thoroughly tests the chronometer to ensure it meets specified accuracy and reliability requirements. This involves subjecting the chronometer to different environmental conditions and performing various tests.

- Conducting temperature, humidity, and shock tests to assess performance

- Inspecting chronometers for defects or potential issues

4. Record Keeping and Documentation

As part of the quality control process, the assembler maintains detailed records of all assembly, adjustment, and testing procedures. This documentation ensures traceability and accountability for the work performed.

- Recording assembly and adjustment details for reference and future troubleshooting

- Documenting test results to demonstrate compliance with specifications

Interview Tips

Preparing thoroughly for a chronometer assembler and adjuster interview is crucial to showcasing your skills and making a positive impression. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you’re applying for. This will help you understand the company’s culture, values, and the key responsibilities of the role.

- Visit the company’s website to learn about their mission, products, and services

- Read industry publications and news articles to stay informed about the latest trends and advancements

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and qualifications. Practice answering these questions concisely and confidently, highlighting your relevant abilities.

- Describe your experience in assembling and adjusting chronometers

- Explain your understanding of chronometer calibration and testing procedures

- Provide examples of your attention to detail and precision in your work

3. Showcase Your Knowledge of Chronometers

Demonstrate your in-depth knowledge of chronometers by discussing their history, principles of operation, and applications. Highlight your understanding of the different types of chronometers and their specific uses.

- Explain the differences between marine chronometers and precision timekeeping chronometers

- Discuss the factors that affect the accuracy and reliability of chronometers

- Describe the latest advancements in chronometer technology

4. Emphasize Your Problem-Solving Skills

Chronometer assemblers and adjusters often encounter technical challenges. Highlight your problem-solving abilities by providing examples of how you have successfully diagnosed and resolved issues related to chronometers.

- Describe a situation where you identified a problem with a chronometer and implemented a solution

- Explain how you troubleshoot and repair chronometers efficiently

- Discuss your knowledge of different troubleshooting techniques and diagnostic tools

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions that show your enthusiasm for the position and the company.

- Inquire about the company’s plans for future product development

- Ask about the opportunities for professional growth and advancement within the organization

- Express your interest in learning more about the company’s commitment to quality and innovation

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Chronometer Assembler and Adjuster, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Chronometer Assembler and Adjuster positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.