Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Button Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Button Maker so you can tailor your answers to impress potential employers.

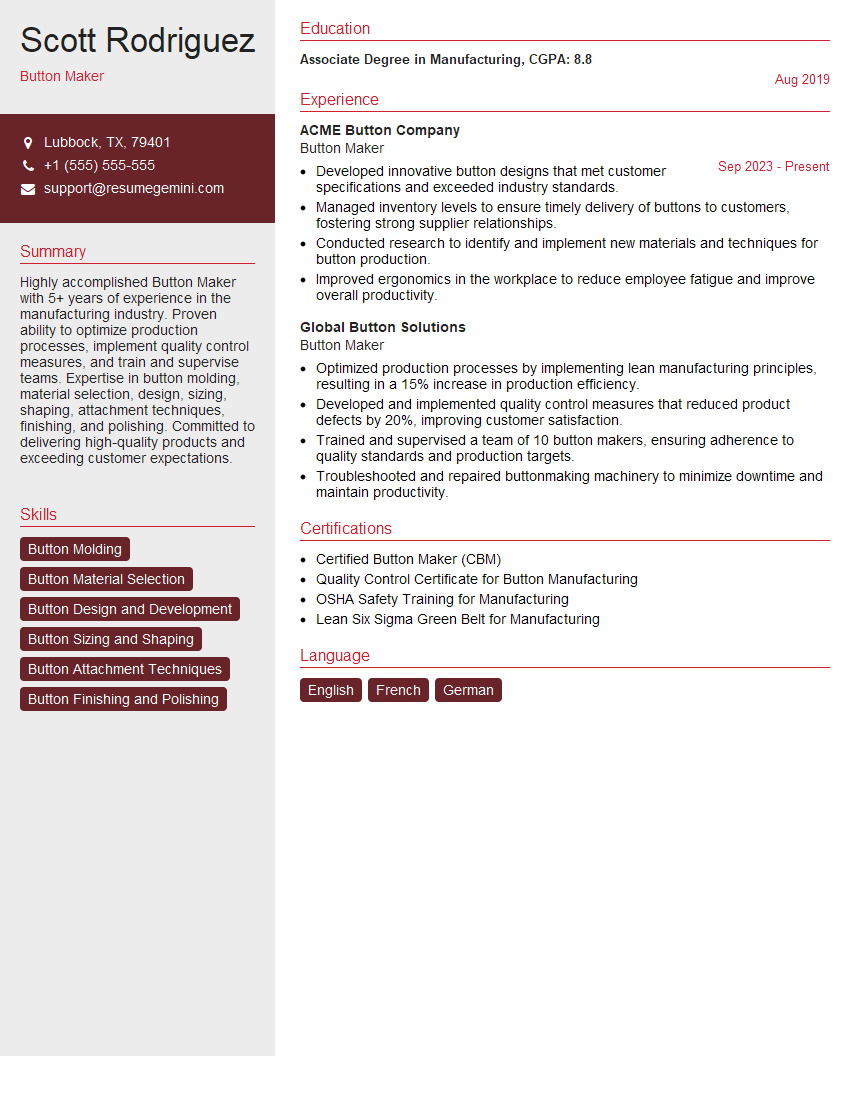

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Button Maker

1. What are the different types of button machines?

- Manual Button Machines: These machines require manual operation to punch out button parts and assemble them.

- Semi-Automatic Button Machines: These machines streamline the process by automatically punching out button parts, leaving the assembly to be done manually.

- Fully-Automatic Button Machines: These advanced machines automate the entire button-making process, including punching, assembly, and packaging.

2. What materials are used in button making and what are their characteristics?

Fabrics

- Cotton: Durable, absorbent, and breathable.

- Polyester: Synthetic, wrinkle-resistant, and moisture-wicking.

- Satin: Smooth, shiny, and luxurious.

Plastics

- Acrylic: Clear, lightweight, and shatter-resistant.

- PVC: Durable, flexible, and waterproof.

- PET: Clear, recyclable, and food-safe.

3. How do you ensure the quality of buttons produced?

- Regularly inspect and calibrate machines for optimal performance.

- Use high-quality materials to create durable and aesthetically pleasing buttons.

- Implement quality control measures to identify and rectify any defects or inconsistencies.

- Seek feedback from customers to identify areas for improvement and address any concerns.

4. What safety precautions are important to observe when operating button-making machines?

- Wear appropriate safety gear, such as gloves and goggles.

- Keep hands away from moving parts to prevent injuries.

- Operate machines only when they are properly set up and grounded.

- Never exceed the machine’s capacity to avoid damage or accidents.

5. How do you troubleshoot common problems that may arise during button making?

- Button parts not feeding correctly: Check for obstructions, damaged parts, or incorrect alignment.

- Buttons coming out misaligned: Adjust the machine settings, such as the punch depth and alignment guides.

- Excessive wear or damage to button molds: Inspect molds for damage, clean them regularly, and replace them if necessary.

- Machine overheating: Check ventilation, clean components, and allow for cooling breaks to prevent breakdowns.

6. Can you describe your experience in optimizing button-making processes for efficiency and cost-effectiveness?

- Streamlined workflow by rearranging equipment and optimizing material handling.

- Identified and implemented cost-saving measures, such as negotiating bulk material purchases.

- Trained team members on efficient operating techniques to reduce production time.

- Analyzed production data to identify bottlenecks and implement solutions for smoother processes.

7. How do you stay up-to-date with advancements in button-making technology?

- Attend industry events, conferences, and workshops.

- Read trade publications and online resources.

- Network with manufacturers and other professionals in the field.

- Research and experiment with new techniques and materials.

8. What is your approach to maintaining a clean and organized work environment in the button-making facility?

- Establish clear cleaning and maintenance schedules.

- Assign responsibilities for specific areas and equipment.

- Provide proper storage and disposal systems for materials and waste.

- Conduct regular inspections to ensure compliance and address any issues promptly.

9. How do you ensure that buttons meet customer specifications and quality standards?

- Review customer specifications thoroughly and confirm understanding.

- Use calibrated measuring and testing equipment to verify button dimensions and other attributes.

- Implement quality control procedures to identify and rectify any deviations from specifications.

- Document quality checks and maintain records for traceability and accountability.

10. What are your strengths and weaknesses as a Button Maker?

Strengths

- Proficient in operating a variety of button-making machines.

- Excellent attention to detail and commitment to quality.

- Ability to troubleshoot and resolve production issues efficiently.

- Strong teamwork and communication skills.

Weaknesses

- Limited experience with advanced button-making techniques.

- Need to improve time management skills in high-volume production environments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Button Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Button Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Button Maker plays a crucial role in the production and maintenance of buttons for various purposes, including clothing, accessories, and promotional material. Their primary duties range from operating button-making machinery to ensuring quality control and managing inventory.

1. Button Production

The core responsibility of a Button Maker involves operating specialized button-making machines. This entails adhering to specific design specifications, selecting appropriate materials, and ensuring smooth production processes.

- Operate button-making machines to create buttons in various sizes, shapes, and materials.

- Adjust machine settings, such as pressure, temperature, and speed, to optimize button production.

2. Design and Materials

Button Makers may contribute to the design and selection of materials used in button production. They ensure that buttons meet specific aesthetic and functional requirements.

- Assist in the selection of button designs, materials, and finishes to meet customer specifications.

- Source and procure high-quality materials, such as fabrics, plastics, and metals, for button production.

3. Quality Control

Maintaining the quality of produced buttons is paramount. Button Makers inspect buttons for defects, ensure they meet established standards, and perform necessary repairs or adjustments.

- Inspect buttons for any defects, including scratches, discoloration, or loose parts.

- Perform repairs or adjustments to defective buttons, ensuring they meet quality requirements.

4. Inventory Management

Button Makers are responsible for managing button inventory, including tracking stock levels, organizing storage, and coordinating with other departments to ensure timely production.

- Maintain accurate inventory records, including stock levels and reorder points.

- Organize and store buttons in designated areas to prevent damage and facilitate retrieval.

Interview Tips

To ace an interview for a Button Maker position, careful preparation is essential. Here are some key tips to help candidates stand out:

1. Research the Company

Before the interview, thoroughly research the company where you’re applying. Understand their history, values, products or services, and any recent news or developments.

- Visit the company website and social media pages to gather information.

- Read industry articles and news reports to stay informed about the company’s performance and reputation.

2. Practice Answering Common Questions

There are several common interview questions that candidates should prepare for. Practicing your responses can boost your confidence and help you articulate your skills and experience effectively.

- Tell me about your experience in operating button-making machines.

- How do you ensure the quality of buttons produced?

- Describe your approach to managing inventory and preventing stockouts.

3. Highlight Transferable Skills

Button Maker positions often require skills that are transferable from other roles. Emphasize your abilities in areas such as attention to detail, problem-solving, and customer service.

- Share examples of how you have demonstrated attention to detail in previous roles.

- Provide instances where you successfully resolved production issues or customer concerns.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally for your interview and arrive on time. Punctuality demonstrates respect for the interviewer’s schedule and professionalism.

- Choose business attire that is clean, pressed, and appropriate for an office setting.

- Plan your route to the interview location in advance to avoid delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Button Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!