Are you gearing up for a career in Cane Splicer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cane Splicer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

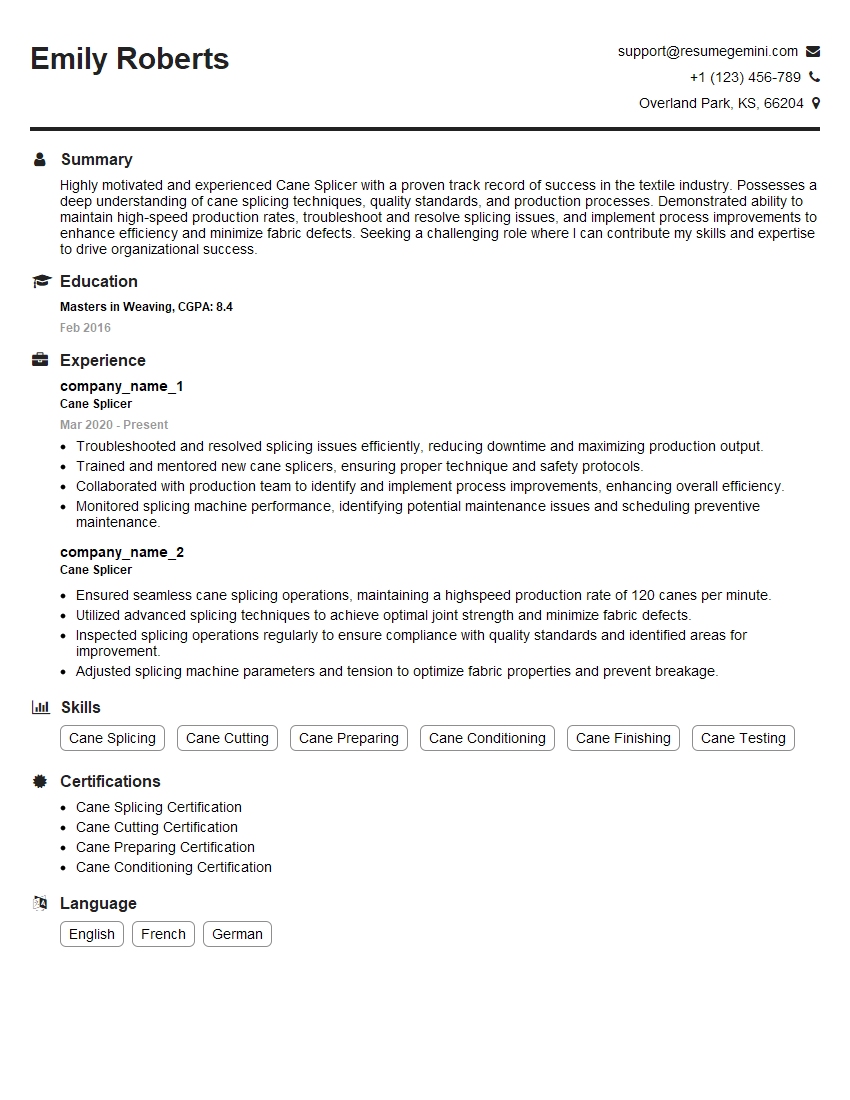

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cane Splicer

1. Describe the key steps involved in splicing cane?

- Preparing the cane by cutting and cleaning it

- Installing splicing rings

- Applying the splice paste

- Wrapping the splice with tape

- Inspecting the splice for defects

2. What types of splicing techniques are used?

Butt Splicing

- Joining two cane stalks together by aligning their ends and wrapping them with tape

- Most commonly used method

Lap Splicing

- Overlapping the ends of two cane stalks and wrapping them with tape

- Provides more strength but takes longer to complete

T-Splicing

- Joining a cane stalk to a cross member

- Used to create support structures

3. How do you ensure a strong and durable splice?

- Use high-quality splicing tape and rings

- Prepare the cane properly before splicing

- Apply the splice paste evenly and wrap the tape tightly

- Allow the splice to dry completely before handling

4. What are the common problems that can occur during splicing and how do you resolve them?

- Insufficient Tape: Use more tape to provide adequate strength and durability.

- Improper Preparation: Clean and cut the cane properly to ensure a smooth and secure bond.

- Contamination: Keep the cane and materials clean to prevent dirt or debris from weakening the splice.

- Moisture: Allow the splice to dry completely before handling to prevent weakening.

5. How do you maintain and repair splice joints?

- Inspect joints regularly: Check for signs of damage or wear

- Tighten loose tape: Rewrap loose tape to maintain strength

- Replace damaged joints: Cut out and replace damaged joints to ensure structural integrity

6. What safety measures should be taken during splicing?

- Wear gloves and protective glasses

- Use sharp tools and keep them in good condition

- Be aware of surroundings and potential hazards

- Follow all safety protocols and guidelines

7. Describe the different types of splicing rings used and their applications

- Standard Rings: General-purpose rings for butt splicing

- Reinforced Rings: Provide additional strength for high-stress applications

- Wide Rings: Distribute pressure more evenly over the splice

- T-Connector Rings: Specifically designed for T-splicing

8. What factors influence the choice of splicing paste?

- Environmental conditions (temperature, humidity)

- Type of cane being spliced

- Desired strength and longevity of the splice

9. Explain the importance of splice alignment and tension

- Proper alignment ensures equal load distribution

- Appropriate tension prevents excessive movement and weakens the splice

- Both factors contribute to the strength and longevity of the splice

10. How do you manage splicing operations in a production environment?

- Establish clear work instructions and quality standards

- Train and supervise splicing crews

- Monitor production rates and quality

- Optimize processes for efficiency and effectiveness

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cane Splicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cane Splicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Cane Splicer

Cane splicers play a vital role in the furniture manufacturing industry, deftly joining raw materials to create the frames of chairs, tables, and other furnishings. Their key responsibilities encompass:

1. Cane Splicing and Weaving

The primary task of cane splicers is to splice and weave cane strips or other materials to form intricate designs on furniture frames. They meticulously align and secure the strips using specialized tools and techniques, ensuring both aesthetics and durability.

2. Quality Control

Meticulousness is paramount in cane splicing, as even minor errors can compromise the structural integrity or visual appeal of the furniture. Cane splicers are responsible for thoroughly inspecting their work at every stage, ensuring that the joints are secure, the patterns are consistent, and the overall quality meets established standards.

3. Machine Operation and Maintenance

Cane splicers skillfully operate splicing machines to efficiently weave and join the cane strips. Their responsibilities include setting up and calibrating the machines, maintaining them in optimal condition, and promptly addressing any technical issues that may arise.

4. Material Handling and Inventory Management

Cane splicers are responsible for handling and managing raw materials, including cane strips, adhesives, and other supplies. They ensure that the materials are stored appropriately and readily available for use. Additionally, they may be involved in inventory control, ensuring sufficient stock levels for ongoing production.

Interview Preparation Tips for Cane Splicers

To excel in a cane splicer interview, candidates should meticulously prepare by researching the industry, familiarizing themselves with the specific requirements of the role, and practicing their responses to potential interview questions. Here are some key tips:

1. Research the Industry and Company

Demonstrating a keen understanding of the furniture manufacturing industry and the company you are applying to will impress the interviewer. Research the company’s history, products, and market position. Familiarize yourself with industry trends and technologies to showcase your knowledge and enthusiasm for the field.

2. Practice Your Answers

Prepare thoughtful and concise answers to common interview questions. Focus on highlighting your skills in cane splicing and weaving, quality control, and machine operation. Use specific examples from your experience to illustrate your capabilities.

3. Emphasize Quality and Attention to Detail

Cane splicing requires a high level of precision and attention to detail. Emphasize your ability to produce intricate designs that meet exacting standards. Describe your quality control processes and how you ensure the durability and aesthetics of your work.

4. Demonstrate Machine Proficiency

Showcase your proficiency in operating cane splicing machines. Explain how you set up, calibrate, and maintain the equipment to achieve optimal performance. Highlight your experience in troubleshooting and resolving technical issues.

5. Prepare Industry-Specific Questions

Asking informed questions about the company’s production methods, material sourcing, or industry innovations demonstrates your genuine interest and enthusiasm for the role. It also provides an opportunity to clarify any details about the position or the company’s expectations.

Next Step:

Now that you’re armed with the knowledge of Cane Splicer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cane Splicer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini